Compact carton packing solution for standardized tasks

Streamline your packaging workflow with a preconfigured solution designed to swiftly handle erecting, filling, and closing processes, ensuring high efficiency and quality with reduced setup times and costs.

Automates Packing, Erecting, Filling, and Closing

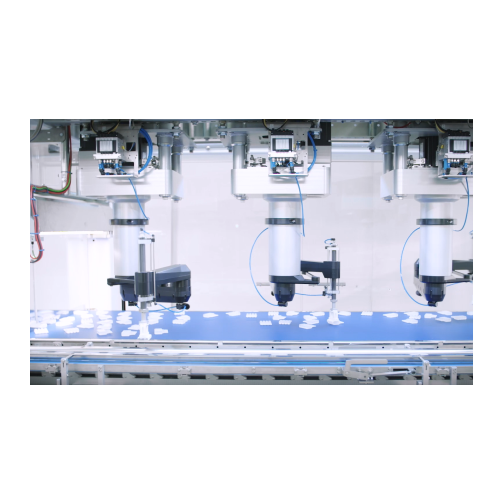

The Schubert Lightline series offers a versatile range of packaging machines designed to optimize efficiency and streamline operations across various industries including food, cosmetics, and pharmaceuticals. These machines are preconfigured for quick integration into your existing production lines, minimizing setup time and costs. Featuring the latest in TLM technology, the Lightline Cartonpacker, Pickerline, and Flowpacker automate tasks such as packing, erecting, filling, and closing, making them ideal for solid products like chocolate bars, juice cartons, and pet food. Capable of high-speed continuous operation, these machines ensure consistent quality with low energy consumption, enhancing overall productivity. The series supports easy scalability and custom performance adjustments, allowing you to meet specific production demands efficiently. Additionally, the robust construction provides durability and minimal maintenance requirements, ensuring a long lifecycle with high system availability. With a focus on sustainable operation, the Lightline series excels in delivering reliable, future-proof solutions that meet rigorous industry standards.

Benefits

- Minimizes setup time and operational costs with preconfigured modules ready for quick deployment.

- Enhances production efficiency in packing and filling operations, reducing labor requirements.

- Lowers energy consumption, promoting sustainable and cost-effective operation.

- Achieves high-quality, consistent results across diverse product forms, ensuring end-product integrity.

- Ensures long-term reliability with proven Schubert functional principles, reducing maintenance intervals.

- Applications

- Food, Beverages, Snacks, Pet food, Confectionery, Cosmetics, Pharma, Bakery products, Dairy

- End products

- Biscuits, Face creams, Juice cartons, Dog kibble, Cat treats, Milk cartons, Tablets, Chocolate bars, Cheese blocks, Snack pouches, Shampoo bottles

- Steps before

- Product preparation, Tray loading, Carton erecting

- Steps after

- Carton sealing, Tray packing, Flow wrapping

- Input ingredients

- products for packaging, naked products, already packed products, trayed products

- Output ingredients

- packaged cartons, trays with products, flowpacks

- Market info

- Schubert Group is renowned for its innovative packaging technology solutions, specializing in modular, highly flexible packaging machines for various industries, ensuring efficiency and precision in production lines.

- Automation

- TLM system

- Configuration

- Preconfigured machine modules

- Cycle time

- Short delivery times, fast commissioning

- Efficiency

- High performance range, low energy consumption

- Footprint

- Compact, smallest of spaces

- Packaging type

- Cartonpacking, Flowpacking, Picking

- System Availability

- High system availability over lifecycle

- Quality

- High quality as per Schubert standards

- Automation level

- High

- Batch vs. continuous operation

- Preconfigured modular system

- Changeover time

- Reduced

- Energy efficiency

- Low energy consumption

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Carton size

- Varied based on product

- Packaging format

- Cartons, Trays, Flowpacks

- Packaging task

- Standardised

- Machine footprint

- Compact

- Discharge method

- Cartonpacking, Flowpacking

- Control panel type

- Intelligent machine control system

- Integration possibilities

- With existing systems

- Preconfigured machine modules

- Yes

- Control panel type

- Intelligent machine control system

- Scalability

- Adaptation to specific performance requirements