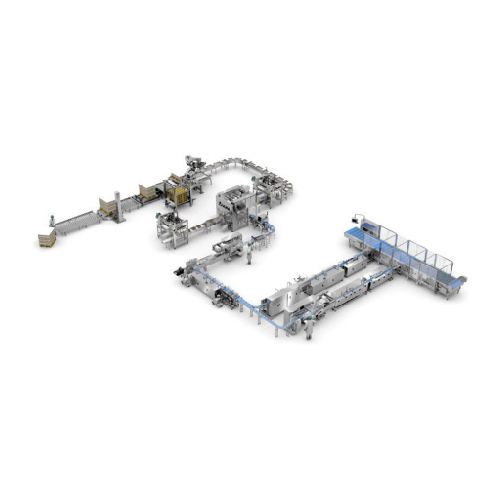

Sweet baked goods packaging solution

Optimize your sweet baked goods packaging process with a fully automated solution designed for high-speed wrapping, case packing, and palletizing, ensuring efficient product handling from alignment to bundling.

Wraps and Packs Sweet Baked Goods Efficiently

The Flow Pack and Case Packer System for Sweet Baked Goods from ULMA Packaging is an integrated solution designed to optimize the packaging processes of bakeries and confectionery manufacturers. This high-speed system utilizes dual flow pack machines to ensure precise wrapping and alignment of products such as croissants, donuts, and pastries. It features an efficient multistage process, starting with a row distribution system that feeds products into flow wrapping lines. The secondary packaging phase groups unitary packages for further case packing. A case erector and tray & hood case packer form display-ready boxes, enhancing retail presentation. Robotic palletizing simplifies the stacking and bundling of packaged goods, optimizing storage and transport efficiency. The system supports continuous operation while maintaining high throughput, making it an ideal choice for manufacturers seeking enhanced productivity and seamless integration into existing production lines.

Benefits

- Enhances packaging speed and precision, minimizing product handling errors.

- Saves labor costs with fully automated, continuous operation.

- Increases shelf appeal with carefully aligned and well-presented multipack boxes.

- Reduces storage space with efficient palletizing and bundling of finished goods.

- Seamlessly integrates with existing production lines, ensuring smooth scaling of operations.

- Applications

- Sweet baked goods, Bakery, Confectionery, Biscuits

- End products

- Cookies, Muffins, Fruit bars, Chocolate bars, Croissants, Cakes, Pastries, Donuts, Brownies, Sweet rolls

- Steps before

- Product alignment, Row distribution, Feeding system alignment

- Steps after

- Secondary packaging, Case packing, Palletizing, Bundling

- Input ingredients

- sweet baked goods, product rows, unitary packages, secondary packages

- Output ingredients

- flow wrapped sweet baked goods, unitary and multipack packages, display boxes, wrapped pallets

- Market info

- ULMA Packaging Spain is renowned for designing and manufacturing innovative, customized packaging solutions for the food, pharmaceutical, and non-food industries, emphasizing advanced automation technology, sustainability, and high-quality service.

- Primary Packaging Speed

- High Speed

- Flow Pack Wrapper Type

- Automatic

- Secondary Packaging Method

- Flow Pack Wrapper

- Case Erector Type

- Automatic

- Palletizing Method

- Robotic

- Automation level

- Fully Automated

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Quick Changeover

- Row distribution system

- Automatic Alignment

- Palletizing method

- Robotic Palletizing

- Product form

- Sweet baked goods

- Package type

- Flow pack, Multipack, Display box

- Flow wrapping system

- Dual high-speed lines

- Row distribution system

- Main product belt

- Feeding system

- Multibel feeding system

- Case packer

- Tray, hood case packer

- Palletizing system

- Robotic palletizing

- Row distribution system

- Customizable to production requirements

- Primary packaging type

- Flow pack wrapper

- Secondary packaging system

- Grouping of unitary packages

- Case packer type

- Tray, hood

- Palletizing system

- Robotic