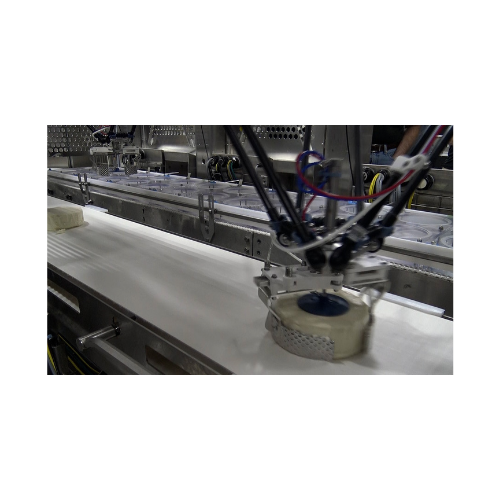

Vision-guided variety pack solution for confectioneries

Achieve seamless variety pack assembly by dynamically loading various products with precision and flexibility, ensuring each flavor or style is placed accurately, even under rapid production speeds.

Sorts and Loads Multi-Flavor Variety Packs

Blueprint Automation’s Vision Guided Variety Pack System is designed to revolutionize multi-flavor pack assembly for snack manufacturers and confectionery producers. Utilizing integrated vision technology, this system inspects, verifies, and dynamically sorts various products into cartons, ensuring precision in loading unbalanced product counts with minimal changeover time. It’s ideal for handling snacks like granola bars and savory crackers, as well as confectioneries such as chocolates and fruit gummies. With pick-and-place rates exceeding 140 items per minute with a single robot, and opportunities to increase throughput using multiple robots or grippers, this system meets high-speed, continuous operation demands. The equipment integrates seamlessly into existing production lines, offering expandable capacity and flexibility in configuration. Its robust design supports solid product types and is engineered for efficient operation in food processing environments, ensuring reliability and high throughput.

Benefits

- Enhances operational efficiency with rapid product orientation and loading.

- Boosts production flexibility by accommodating unbalanced and varied product counts.

- Increases throughput with high-speed pick-and-place capabilities.

- Minimizes changeover time for seamless transition between product types.

- Integrates vision guidance for improved accuracy and quality assurance.

- Applications

- Cookies, Baked goods, Granola bars, Snacks, Chocolates, Snack foods, Confectionaries

- End products

- Chocolate truffles, Energy bars, Pretzel sticks, Assorted fruit gummies, Savory crackers, Shortbread cookies, Layered wafer bars, Party mix trail snacks, Macadamia nut cookies

- Steps before

- Sorting, Inspection, Product preparation

- Steps after

- Cartoning, Tray insertion, Quality check

- Input ingredients

- naked product, packaged product, flow wrapped products, granola bars, cookies, snack foods, chocolates, confectioneries, baked goods, bulk product

- Output ingredients

- variety pack, product tray, carton, final packaged product, kit assembly

- Market info

- BluePrint Automation is known for designing and manufacturing innovative packaging automation systems, specializing in end-of-line robotic case packing solutions for various industries, enhancing operational efficiency and product handling with a strong reputation for quality and innovation.

- Pick,Place rates

- 140+ per minute with a single robot

- Automation

- Vision guided, robotic

- Capacity

- Expandable for any product count

- Flexibility

- Load unbalanced product counts

- Product Detection

- Integrated vision system

- Cycle Time

- Dependent upon application specifics

- Loading

- Dynamic loading of product into cartons

- Working Mechanism

- Robot with vision-guided system

- Integrated Steps

- Inspection, verification, re-orientation, placement

- Automation Level

- Vision-guided robotics

- Changeover Time

- Minimal

- Batch vs. Continuous Operation

- Batch for variety pack assembly

- Flexibility

- Handles naked and packaged, different flavors/styles

- Efficiency

- High throughput with 140+ picks per minute

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Discharge method

- Dynamic loading

- Modularity

- Expandable for any product count

- Control panel type

- Touchscreen HMI

- Integration capabilities

- Vision system integration

- Product handling flexibility

- Naked and packaged products

- Pick,Place speed

- 140+ per minute