Chocolate transport system for feeding and packaging

Enhance your chocolate production with a versatile transport system designed for efficient feeding and seamless packaging, ensuring precision in handling both liquid chocolate and solid products like drops and flakes.

Feeds and Transports Chocolate Products Efficiently

The GIRAFFE Belts from Prefamac Chocolate Machines is a versatile transport system specifically designed for the chocolate and confectionery industries. This tailor-made equipment effectively addresses production challenges by providing a continuous and automated transport solution for solid, liquid, and granule chocolate products. It’s designed to integrate seamlessly into existing production lines, feeding materials to melting kettles, tempering machines, and packaging systems.

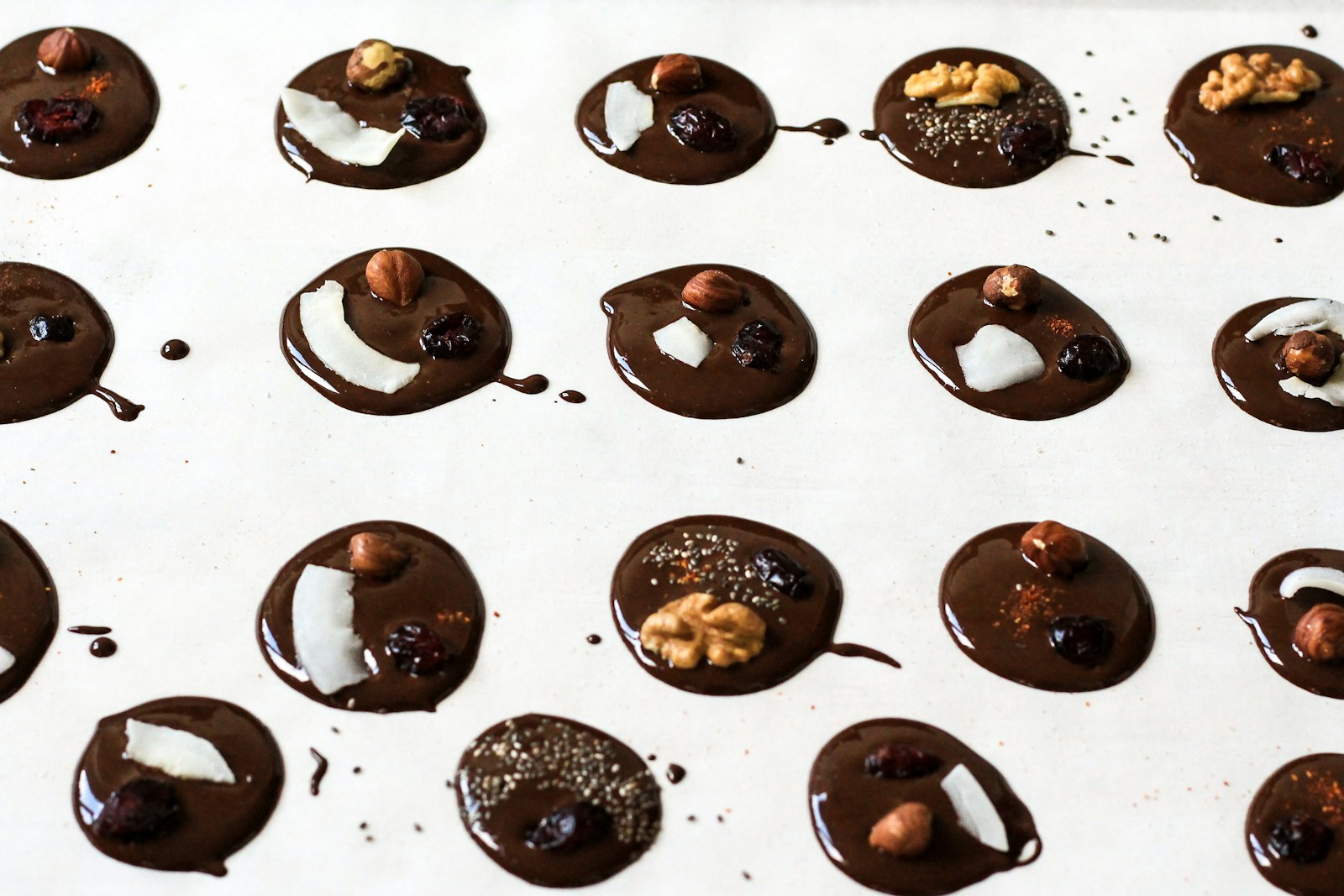

With the ability to customize transport speed and curvature, the GIRAFFE Belts cater to a range of operational needs, from high-speed processing to gentle handling. The system supports applications like feeding chocolate drops and flakes into packing boxes or bags and distributing decoration materials consistently. Engineered for flexibility, the GIRAFFE Belts accommodate a variety of chocolate products, such as bars, pralines, and truffles, enhancing productivity in chocolate production and biscuit manufacturing environments.

Constructed from durable stainless steel, the GIRAFFE promises longevity and minimal maintenance, demonstrating robust performance even under demanding conditions. It features a central control panel for intuitive operation and comes equipped with a hinged grill and a drum motor with adjustable speed, ensuring reliable and safe transport of materials. The system’s mobility, courtesy of heavy-duty castors, allows easy reconfiguration of production floor layouts as needed.

Benefits

- Enhances production efficiency with customizable speed settings for optimal material handling.

- Minimizes labor strain by positioning materials at ergonomic heights, reducing the risk of worker injury.

- Increases operational flexibility with easy mobility, allowing quick adjustments to production layouts.

- Provides robust performance with low maintenance needs, ensuring long-term reliability.

- Supports diverse chocolate processing needs, from feeding to packing, streamlining entire production processes.

- Applications

- Chocolate molding, Chocolate flakes, Confectionery, Sweets, Chocolate, Chocolate drops, Chocolate decorations

- End products

- Chocolate truffles, Milk chocolate drops, Chocolate molds, White chocolate decorations, Chocolate pralines, Chocolate-covered nuts, Chocolate bars, Chocolate-coated sweets, Chocolate-covered biscuits, Dark chocolate flakes

- Steps before

- Melting, Tempering, Decoration preparation

- Steps after

- Packing, Boxing, Bagging

- Input ingredients

- chocolate, decoration material, chocolate drops, chocolate flakes

- Output ingredients

- melted chocolate, decorated products

- Market info

- Prefamac is known for manufacturing high-quality chocolate processing equipment, including tempering, enrobing, and cooling machines. The company is recognized for innovative and custom-engineered solutions tailored to the confectionery industry, emphasizing precision, efficiency, and reliability.

- Transport system width

- 280–1500 mm

- Total length

- Customizable

- Height of activity (adaptable)

- Customizable

- Required curvature

- Customizable

- Desired speed

- Variable, m/min

- Electricity

- 380-420V 50Hz / 220-240V 60Hz / 110-120V 60Hz

- Material

- Stainless Steel

- Standard Strap Width

- 400 mm

- Operating Speed

- Adjustable

- Drum Motor Position

- Upper side

- Storage Tank Size

- Customizable

- Working Mechanism

- Conveyor Belt

- Batch vs. Continuous Operation

- Continuous

- Automation Level

- Central Control Panel

- Mobile Ability

- Heavy Duty Castors

- Speed Control

- Adjustable Speed

- Materials Handled

- Chocolate, Decoration Material

- Operating Speed Range

- Customizable

- Tailor-made Design

- Available

- Abrasion resistance

- Yes

- Biological compatibility

- Food-grade

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel

- Density/particle size

- Various chocolate forms

- Container size and shape

- Boxes / Bags

- Machine footprint

- Compact

- Material

- Stainless steel

- Mobility

- Equipped with heavy duty castors

- Storage tank height

- 1 meter

- Strap width

- 400 mm standard or on request

- Customizable width

- 280–1500 mm

- Customizable speed

- Variable

- Discharge method

- Outlet funnel

- Custom design options

- Tailor-made

- Control panel type

- Central control

- Protection features

- Hinged stainless steel grill

- Control panel type

- Central control panel

- Operating speed

- Adjustable speed

- Tailor-made design

- Custom sizes and configurations

- Height adaptation

- Adjustable activity height

- Material

- Stainless steel construction

- Transport system width

- Customizable from 280 mm to 1500 mm

- Machine integration

- Connection with melting kettles, decoration machines

- Storage capacity

- Custom storage tank sizes

- Powder product integration

- Compressed air connection