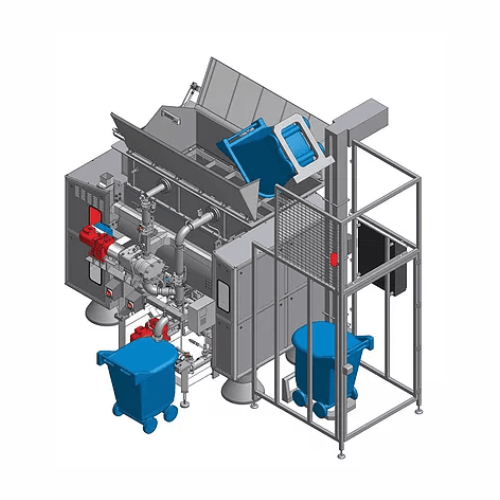

Industrial product rework system

Efficiently rework products while minimizing waste with a robust system designed for precise mixing and heating, adaptable for both batch and continuous operations in diverse production environments.

Mixes, Heats, and Reworks Diverse Products

The Product Rework System from MacIntyre Chocolate Systems is engineered for precision and reliability in processing applications. This robust system efficiently mixes, heats, and reworks solid, liquid, and slurry products, suitable for bakery, confectionery, and pharmaceutical industries. Utilizing a single or twin shaft arrangement and optional paddle mixing actions, it supports batch and continuous operations. With a capacity ranging from 750kg to 1000kg, the system features a jacketed trough for steam or electric heating. The high-efficiency geared motor drive reduces energy consumption, while stainless steel construction ensures hygiene and longevity. Integration options include fixed or variable speed motors, PLC control, and customization to fit into existing production lines. Optional CIP systems streamline cleaning for reduced downtime.

Benefits

- Enhances production efficiency with energy-saving geared motor drives.

- Provides versatile processing for both wet and dry mixing applications.

- Simplifies integration with existing systems through customizable control options.

- Minimizes maintenance time with CIP-ready design for quick, effective cleaning.

- Ensures long-term reliability with robust stainless steel construction.

- Applications

- Bakery, Confectionery, Food products, Pharmaceutical

- End products

- Chocolate truffles, Processed food recyclables, Pralines, Medicinal tablets, Chocolate bars, Cream fillings, Dough for pastries, Dietary supplements

- Steps before

- Grinding, Melting, Mixing

- Steps after

- Recycling, Quality Control, Packaging

- Input ingredients

- raw materials, bakery ingredients, confectionery ingredients, pharmaceutical ingredients, recyclable food products

- Output ingredients

- reworked products, mixed products, processed ingredients

- Market info

- Macintyre Probat is known for manufacturing specialized industrial machinery, particularly in the cocoa and chocolate processing industry, offering engineered-to-order solutions with a reputation for innovation and reliability in their equipment designs.

- Capacity

- 750kg – 1000kg

- Paddle mixing actions

- Type D, Type T

- Heating Type

- Steam or electric immersion heating

- Outlet Type

- Larger bottom outlet, gate or ball valve

- Temperature Monitoring

- Product temperature probe PT100

- Drive Options

- Fixed speed or variable speed

- Shaft Arrangement

- Single shaft or twin shaft

- Control System

- PLC Control

- Construction Material

- Stainless steel

- Cleaning System

- CIP System

- Batch vs. continuous operation

- Batch

- Automation level

- Manual / PLC

- Energy efficiency

- Energy efficient geared motor drive assembly

- Cleaning method

- CIP

- Single shaft or twin shaft arrangements

- Yes

- Heating options

- Steam heating / Electric immersion heating

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- Designed for CIP

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Density/particle size

- Variety of food products

- Multi-functionality

- Wet and dry mixing

- Machine footprint

- 750kg – 1000kg capacity

- Construction Material

- Stainless steel

- Configuration

- Single shaft or twin shaft arrangements

- Heating method

- Steam or electric immersion heating

- Discharge method

- Larger bottom outlet, with gate or ball valve

- Trough arrangement

- Jacketed trough

- Control panel type

- PLC Control

- Integration possibilities

- Linking into existing PLC controlled system

- Machine color

- Painted to client's specification

- Speed control

- Fixed speed or variable speed (additional cost)

- Mixing actions

- Type D, type T paddle mixing actions

- Heating options

- Steam heating or electric immersion heating

- Material supply connections

- Connection in lids

- Outlet valve type

- Gate or ball valve

- Shaft arrangement

- Single shaft or twin shaft

- Hygienic design

- Robust and hygienic operating system

- CIP System

- Configured to suit customer requirements

- Tailored Configuration

- Tailored to suit customer’s requirements