Accumulation conveyor for controlled feeding in packaging lines

Ensure seamless product flow and enhance efficiency in your packaging line with a conveyor system designed to manage and stabilize irregular product distribution, optimizing feeding precision for downstream wrapping machines.

Controls and Balances Product Flow

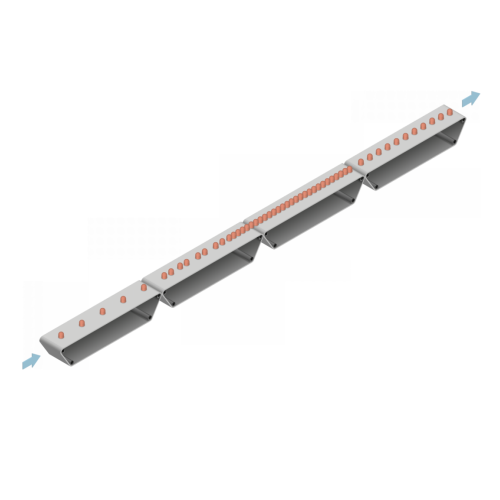

The Accumulation Conveyor by Theegarten-Pactec is engineered to manage the challenges of high-speed packaging lines for confectionery and food products. Featuring a multi-stage design with a three-phase motor and integrated frequency controller, it ensures continuous operation by compensating for irregular product flow. This system is optimized for a wide range of products, including chocolates, candies, and tablets, enhancing the efficiency of upstream and downstream processes. Designed for ease of maintenance, it includes quick tensioning devices and removable support plates for straightforward cleaning. The conveyor is available with optional cooling to accommodate temperature-sensitive items. Seamlessly integrate this component into your production line to enhance product handling, with custom configurations available to meet specific operational needs.

Benefits

- Optimizes product flow for continuous packaging operations, minimizing bottlenecks.

- Lowers maintenance time and costs with easy-access design and quick tensioning.

- Enhances product quality with precise control over temperature-sensitive items via optional cooling.

- Increases efficiency through seamless integration with existing wrapping systems.

- Customizable to fit specific operational requirements, ensuring compatibility with diverse product lines.

- Applications

- Soft caramels, Bouillon cubes, Hard candies, Chocolate products, Bubble gum, Cereals, Sweets, Jelly products, Effervescent tablets, Dishwasher tablets, Chewing gum

- End products

- Assorted caramel chews, Gummy bears, Fruit-flavored jellies, Cornflakes, Spearmint chewing gum, Lavender-scented dishwasher tablets, Muesli mix, Chicken bouillon cubes, Bubble gum balls, Fizzy vitamin tablets, Dark chocolate truffles, Milk chocolate bars

- Steps before

- Product Processing, Distribution Preparation, Bulk Delivery

- Steps after

- Wrapping, Final Packaging, Distribution to Packaging Machines

- Input ingredients

- irregular product flow, product rows, bulk products, chocolate products, hard caramels, jelly products, chocolate balls, chocolate eggs

- Output ingredients

- controlled feeding, packaged chocolate products, packaged hard caramels, packaged jelly products, packaged chocolate balls, packaged chocolate eggs

- Market info

- Theegarten-Pactec is known for its expertise in manufacturing highly specialized packaging machines for small-sized confectionery products, offering innovative, flexible, and efficient solutions tailored to various customer needs in the industry.

- Execution Stages

- Single- to four-stage

- Motor Type

- Three-phase motor

- Frequency Control

- Integrated within the switch cabinet

- Cleaning Access

- Easy access through removable conveyor support plates

- Maintenance Feature

- Quick tensioning devices for conveyor belts

- Product Transfer

- Smooth transfer with 10 mm diameter return shafts

- Optional Feature

- Cooling of the conveyors

- Automation level

- PLC controlled

- Batch vs. continuous operation

- Continuous

- Changeover time

- Quick tensioning devices

- Cleaning method

- Easy access for cleaning

- Cooling option

- Optional cooling of conveyors

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product size and shape variation

- Single block, individual rows, or bulk

- Machine footprint

- Single- to four-stage execution

- Motor type

- Three-phase motor driven conveyor

- Control type

- Frequency controller integrated within the switch cabinet

- Cleaning access

- Easy access for cleaning through removable conveyor support plates

- Maintenance features

- Quick tensioning devices for the conveyor belts

- Product transfer and waste management

- All product transfers and scrapers with underneath sliding waste trays

- Return shaft diameter

- 10 mm for smooth product transfer

- Cooling option

- Optional

- Cooling option

- Available

- Conveyor stages

- Single- to four-stage execution

- Motor type

- Three-phase motor driven

- Conveyor belt tensioning

- Quick tensioning devices