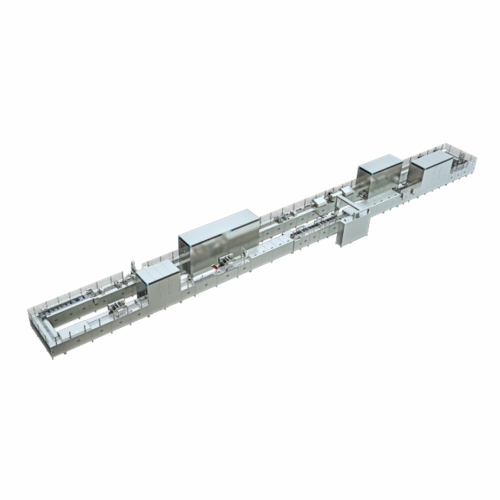

Automatic chocolate shell moulding line

Enhance your production capabilities with a cutting-edge moulding line that delivers precision-filled chocolates, from multi-layered varieties to nut-infused treats, ensuring seamless integration and high-speed output in your confectionery operations.

Moulds and Cools Diverse Chocolate Products

The Automatic Chocolate Shell Moulding Line MKSL-A (450/900) by Memak offers a comprehensive solution for chocolate manufacturers seeking versatility and efficiency in their production lines. Designed for producing a variety of center-filled and solid chocolates, it features an automated process encompassing moulding, cooling, and demolding to streamline operations. With a capacity of 12-18 shots per minute, handling up to 900 kg/h, this line supports high-speed, continuous production suitable for confectionery and bakery sectors. The integration of PLC controls enhances automation and adaptability, while optimized cooling systems ensure precise crystallization of chocolate shells. The robust design accommodates various fillings, from crispies to whole nuts and liquids, enabling diverse product offerings. Engineered from durable materials, the line is easy to sanitize and maintain, ensuring compliance with industry standards and minimal downtime.

Benefits

- Enhances production flexibility with diverse chocolate filling options.

- Increases output efficiency with high-speed, continuous operation.

- Minimizes labor intervention through fully automated process control.

- Ensures product consistency with precise moulding and cooling stages.

- Simplifies maintenance with corrosion-resistant construction and easy-to-clean design.

- Applications

- Sweets, Chocolates, Confectionery, Snacks

- End products

- Liquid filled chocolates, 50% granule filling chocolates, Center filled chocolates with crispies, Double layers filled chocolates, Solid chocolates, Cream filled chocolates, Whole hazelnut chocolates, Three colored chocolates, Center filled chocolates with peanut, Double colored chocolates, Center filled chocolates with walnut, Caramel filled chocolates, Granule-filled chocolates (2-4 mm), Jelly filled chocolates, Center filled chocolates with hazelnut, Center filled chocolates with almond, Center filled chocolates with sesame

- Steps before

- Pre-mixing, Cooling, Demolding

- Steps after

- Packaging

- Input ingredients

- chocolate, cream, colored chocolates, filled chocolate mixtures, granules (2-4 mm), whole hazelnuts, jelly, caramel, liquids

- Output ingredients

- solid chocolates, cream filled chocolates, double or three colored chocolates, double layers filled chocolates, center filled chocolates, chocolates with crispies, chocolates with almond, chocolates with walnut, chocolates with hazelnut, chocolates with peanut, chocolates with sesame, jelly filled chocolates, caramel filled chocolates, liquid filled chocolates, %50 granule filling chocolates

- Market info

- Memak is known for manufacturing high-quality, engineered-to-order equipment primarily for the food processing industry, with a reputation for innovation, precision engineering, and reliable customer support.

- Capacity

- 12-18 shots/min up to 450 kg/h

- Capacity

- 12-18 shots/min up to 900 kg/h

- Total Power

- 85 Kw

- Total Power

- 88 Kw

- Automation

- Automatic demolding system

- Product Variety

- Solid chocolates, cream filled chocolates, double or three colored chocolates, etc.

- Cooling System

- Cooling paternosters

- Cooling System

- Cooling paternosters

- Demolding System

- Automatic demolding

- Product Flexibility

- Solid and filled chocolates

- Automation Level

- Automatic

- Production Capacity

- 450 kg/h / 900 kg/h

- Batch vs. Continuous Operation

- Batch

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size and shape

- Various shapes and sizes

- Product variety

- Solid, cream-filled, liquid-filled chocolates

- Shell or Mould Design

- Automatic Shell Moulding

- Footprint

- Compact dimensions suitable for ETO setup

- Cooling System

- Cooling paternosters included

- Demolding System

- Automatic demolding system

- Material handling

- Integrated granule and nut filling system

- Capacity

- 450 kg/h, 900 kg/h

- Control Type

- Automatic control for moulding process

- Production options

- Solid, cream filled, multi-colored chocolates

- Filling capabilities

- Nut, jelly, caramel, liquid, granule fillings

- Cooling system

- Cooling paternoster

- Demolding system

- Automatic