High-speed overwrapping for display boxes

Achieve seamless overwrapping of display boxes with ultra-high-speed capabilities, ensuring optimal product protection and presentation with precision sealing and film splicing features.

Overwraps and Seals Display Boxes Efficiently

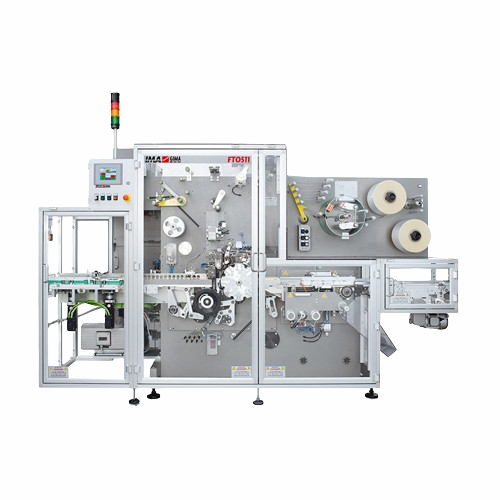

The FTO511 from IMA Group is an ultra-high-speed overwrapping machine specifically engineered for confectionery and food packaging solutions. Unique for its continuous carton feeding system, the FTO511 prevents product collision and ensures the seamless, careful handling of items such as chocolate bars, candy boxes, and biscuit packets. Operating at up to 500 packs per minute, it meets the demands of high-volume manufacturers with precision. Equipped with an inline tear-tape unit, double reel holder, and automatic film splicing device, it efficiently processes all heat-sealable films like PP, PVC, and Cellophane. The machine’s automation capabilities facilitate smooth integration into existing production lines, enhancing throughput without compromising package quality. With a compact footprint and easy maintenance access, the FTO511 offers reliable operation, reducing downtime to support continuous production goals. Additionally, its engineering support allows for customization to address specific packaging requirements.

Benefits

- Increases production efficiency by processing up to 500 packs per minute.

- Minimizes product damage with continuous carton feeding and careful handling.

- Enhances package presentation with precise sealing and film control.

- Customizable design adapts to specific packaging needs and workflows.

- Integrates seamlessly into existing lines, streamlining operations and reducing labor.

- Applications

- Snacks, Confectionery, Packaging, Sweets, Display boxes

- End products

- Display box sets for sweets, Chocolate boxes, Mints, Truffle boxes, Snack bars, Biscuit packets, Chocolate bars, Wrapped cough drops, Gum packs, Candy boxes, Confectionery bundles

- Steps before

- Cartoning, Dosing, Pressing, Pouch filling, Form Fill and Seal, Horizontal form fill and seal

- Steps after

- Case packing, Palletizing

- Input ingredients

- display boxes, heat-sealable films, PP, PVC, Cellophane

- Output ingredients

- overwrapped display boxes, enhanced package appearance, sealed packages

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Production Speed

- Up to 500 ppm

- Automation Features

- Automatic film splicing

- Material Compatibility

- PP, PVC, Cellophane

- Film Width

- Up to 150 mm

- Reel Diameter

- Max 300 mm

- Core Diameter

- Min 76.2 mm

- Average Power Consumption

- 20 kW

- Operating Pressure

- 6 bar

- Maximum Air Consumption

- 100 Nl/min

- Machine Weight

- 2, 200 Kg

- Inline Features

- Inline tear-tape unit, double reel holder

- Automation level

- Automatic with PLC control

- Product handling

- Continuous carton feeding system

- Tear-tape application

- Inline integrated unit

- Film handling

- Double reel holder and automatic film splicing

- Flexibility

- Handles various heat-sealable films

- Operation speed

- Up to 500 ppm

- Energy Consumption

- 20 kW

- Operation pressure

- 6 bar

- Air consumption

- 100 Nl/min

- Heat-sealable films

- PP, PVC, Cellophane

- Web-width

- Up to 150 mm

- Core diameter

- Min. 76.2 mm

- Web-width

- Up to 150 mm

- Reel diameter

- Max 300 mm

- Core diameter

- Min 76.2 mm

- Integration possibilities

- Continuous carton feeding system

- Tear-tape unit

- Inline

- Reel holder

- Double

- Film splicing device

- Automatic