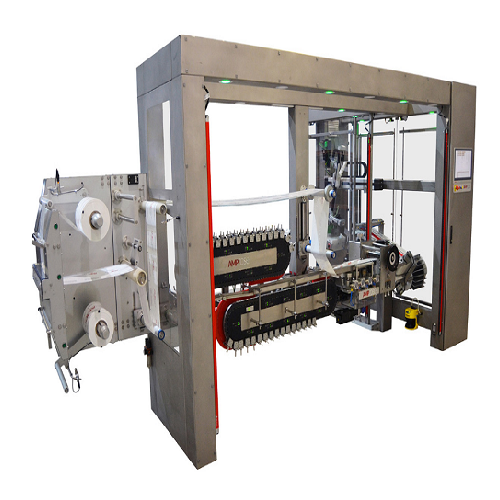

Multipack flowrapping system

Streamline your packaging process with a multipack flowrapping system that effortlessly handles diverse product configurations, minimizing downtime with touch-of-a-button adjustments.

Multipacks and Wraps Diverse Product Ranges

The XPax Multipack Flowrap System from A.M.P Rose is engineered for comprehensive packaging tasks, combining flowrapping with the latest linear transport technology. This system excels in wrapping, packing, and case packing operations, adeptly handling a wide array of products such as protein bars, gummy bears, and electronic components. What distinguishes the XPax is its Beckhoff XTS integration, which merges rotary and linear transport benefits for precise, high-speed product handling at up to 4 meters per second, without jerking.

With its touch-button features, you can easily alter pack sizes and product configurations, making it ideal for operations requiring frequent changeovers. The XPax system is PLC-controlled, offering robust integration possibilities and real-time data analysis to enhance production efficiency. Available in standard powder-coated or optional stainless steel finishes, it provides excellent material resistance and hygienic design. Maintenance needs are minimized thanks to a friction-reducing, passive mover system, ensuring reduced wear and prolonged equipment life. Customization options further align this multipack system to your specific production requirements, ensuring seamless line integration and peak operational performance.

Benefits

- Enhances production efficiency with rapid changeovers and minimal downtime.

- Provides versatile packaging options for a wide range of product sizes and configurations.

- Real-time data analysis identifies inefficiencies, optimizing operational performance.

- Reduces maintenance needs with low-friction, wear-resistant components.

- Compact design saves floor space while ensuring easy access and operation.

- Applications

- Jellies, Wafers, Biscuits, Snacks, Marshmallows, Hard candies, Chocolates, Hardware products, Toffees, Gum, Sweets, Food products, Caramel

- End products

- Gummy bears, Butter cookies, Electronic components, Mint toffees, Dark chocolate bars, Bubble gum, Jelly beans, Cereal bars, Caramel chews, Metal fasteners, Wafer cookies, Lollipops, Marshmallow treats, Protein bars

- Steps before

- Primary Wrapping

- Steps after

- Case Packing, Shelf Ready Display Packing

- Input ingredients

- bars, food products, hardware items, product layers, pack materials

- Output ingredients

- multipacks, shelf ready display cases, flowrapped products, case packed products

- Market info

- AMP Rose is renowned for manufacturing and supplying high-quality machinery for the confectionery, chocolate, and snack industries, offering innovative solutions and engineered-to-order equipment tailored to meet specific customer needs.

- Output speed

- Up to 4 metres/second

- Transport system type

- Beckhoff XTS (eXtended Transport System)

- Motor type

- Linear motor with power electronics

- Mover weight

- Less than 350g

- Flowrap machine type

- Full servo driven horizontal wrapping machine

- Wrapping material

- Heat or cold seal

- Material flow speed

- Up to 4m/s

- Synchronization

- Fully synchronised with XTS feed system

- Changeover speed

- At the touch of a button

- Automation level

- Industry 4.0 data and analysis capabilities

- Automation level

- Full servo, touch button controls, PLC

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Minimal, due to touch button features

- CIP/SIP

- Information not provided

- Cleaning method

- Manual, due to compact and accessible layout

- Energy efficiency

- Optimized by design, minimal energy use

- Flexibility

- Touch button collation changes

- Integrated steps

- Multipack and case packer, inline process

- Working mechanism

- Linear and rotary system, Beckhoff XTS

- Unique layout

- Compact, small footprint

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product type versatility

- Food to hardware

- Compact footprint

- Yes

- Control panel type

- Windows based HMI screen

- Discharge method

- Flowrap with XTS feed system

- Control panel type

- Windows based HMI

- Machine configuration

- Flowrap / Multipack

- Material finish

- Powder coated / Stainless steel

- Sealing jaw type

- Rotary / Box motion

- Integration possibilities

- Automation, Robotics