Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for seamlessly forming and assembling different carton shapes with high-speed precision.

Forms and Fills Cartons Rapidly

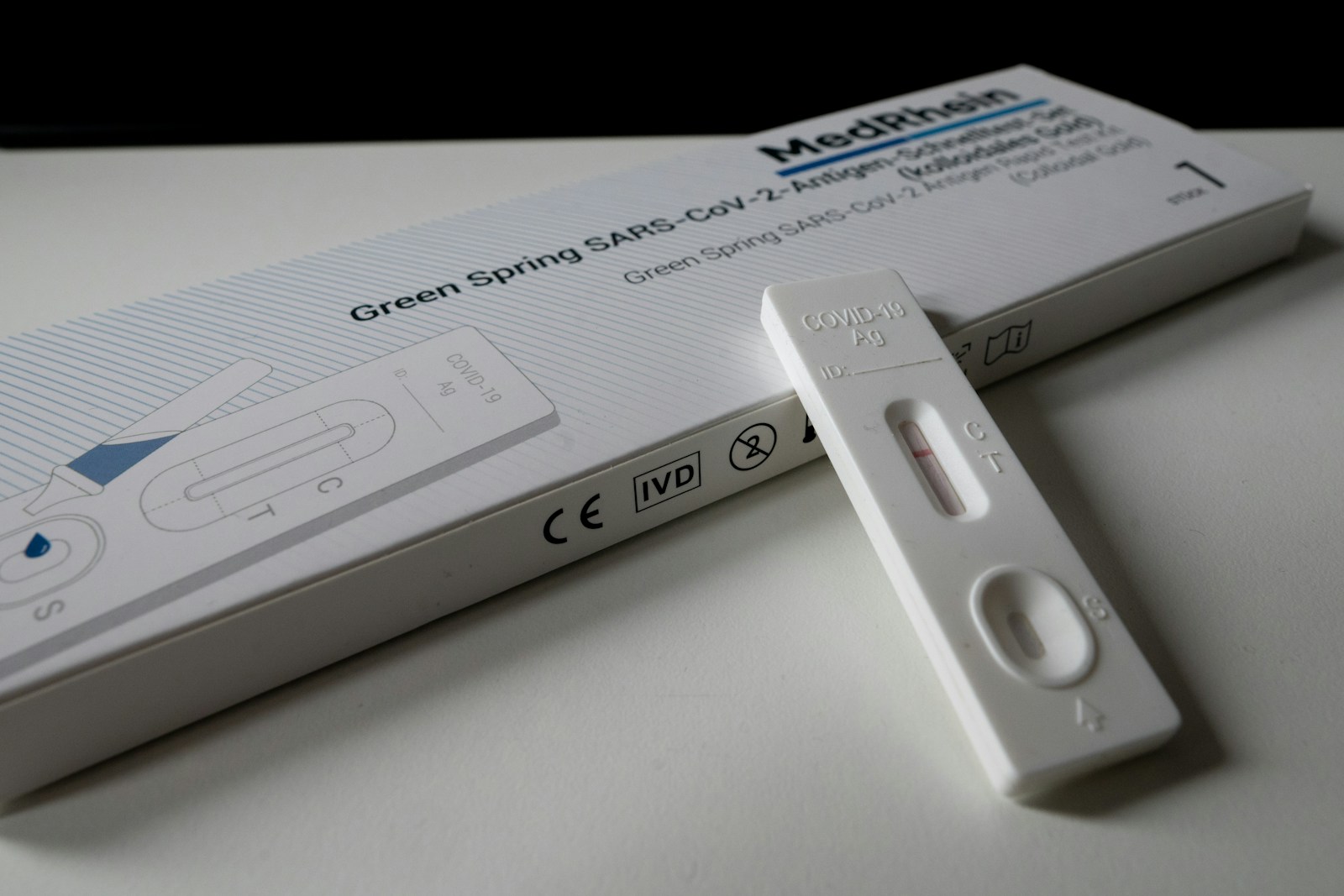

The Topload Cartoner CFM from Viking Masek is a robust carton forming and filling machine designed to meet the demands of various industries, such as food, beverage, and healthcare. It distinguishes itself with its capability to run different carton shapes through single, double, or triple head operation, offering flexibility for diverse product lines. The machine seamlessly integrates into high-speed production environments, supporting applications from packaging granola bars to medical testing kits. With a throughput of up to 150 cartons per minute, it ensures efficient and continuous operation. Equipped with servo drives and controlled by Siemens or Allen Bradley systems, the Topload Cartoner CFM offers precise automation with remote diagnostics capability. Constructed from rugged stainless steel, it is both durable and hygienic, suitable for stringent industry standards. Optional features include various closure systems and extended carton magazine for versatile production needs. Maintenance is streamlined through off-the-shelf components and a built-in vacuum pump, ensuring minimal downtime and easy access for cleaning and part replacement.

Benefits

- Enhances production efficiency with high-speed operation up to 150 cartons per minute.

- Offers flexibility with single, double, or triple head configuration for diverse product lines.

- Minimizes downtime with easy format changeover and off-the-shelf components.

- Reduces labor costs through automated servo-controlled systems and remote diagnostics.

- Ensures durability and compliance with rugged stainless steel construction and IP54 design.

- Applications

- Treats, Medical devices, Snacks, Bakery, Cheese, Organic foods, Medical testing kits, Fish, Liquids, Food, Fresh fruit, Non-food products, Beans, Supplies, Pills, Cannabis, Capsules, Candy, Pasta, Pet food, Individual quick frozen (iqf), Nuts, Natural, Rice, Health, Cereal, Beverage, Meat, Coffee, Medical, Vegetables, Poultry, Powders

- End products

- Spaghetti, Mixed nuts packs, Packaged chicken breasts, Canned beans, Cheddar cheese slices, Instant coffee packets, Vitamin supplements, Potato chips, Packaged spinach, Protein powder, White rice, Printer cartridges, Fresh apple slices, Granola bars, Dry dog food, Canned tuna, Pain relief capsules, Bandages, Cornflakes, Syringes, Rapid covid-19 test kits, Frozen vegetables, Cat treats, Muesli base flakes, Organic granola, Sliced bread, Cannabis-infused edibles, Chocolate bars, Bottled cold-pressed juice

- Steps before

- Carton Supply Preparation, Format Changeover Setup

- Steps after

- Carton Packing, Closure Application, Quality Inspection, Carton Palletizing

- Input ingredients

- flat carton blanks, packaging materials, carton shapes

- Output ingredients

- assembled cartons, filled cartons, sealed cartons

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Max Speed

- 150 cpm

- Carton Size (Intermittent)

- Min 40 mm x 50 mm x 20 mm

- Carton Size (Intermittent)

- Max 400 mm x 600 mm x 400 mm

- Configuration

- Single, double, or triple head

- Closure Systems

- Lock style, hot melt, or hot air systems

- Machine Footprint

- 1500 - 1800 mm W x 2600 mm L x 2100 - 2400 mm H

- Weight

- 800 - 1400 kg

- Air Pressure

- 6 bar (15–18 CFM at 90 PSI)

- Power Supply

- 4 - 12kVA

- Servo Drives

- Included

- Construction Material

- Rugged stainless steel

- IP Rating

- IP54 construction

- Automation

- Siemens or Allen Bradley controls

- Working mechanism

- Topload cartoning

- Automation level

- PLC-controlled

- Changeover time

- Easy format changeover

- Batch vs. continuous operation

- Continuous

- Carton configuration

- Single, double, or triple head

- Cleaning method

- Manual clean due to accessibility

- Carton supply control

- Controlled carton supply

- Abrasion resistance

- High durability

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Cleanability

- Easy clean surfaces

- Density/particle size

- Compatible with various carton shapes

- Machine Footprint

- 1500 - 1800 mm W x 2600 mm L x 2100 - 2400 mm H

- Weight

- 800 - 1400 kg

- Physical Construction Material

- Rugged stainless steel construction

- Integration

- Remote diagnostics

- Frame size

- Different frame sizes to accommodate large carton size range

- Closure system

- Various styles of closure systems

- Forming head

- Adjustable forming head

- Carton magazine

- Extended carton magazine

- Construction type

- IP65 washdown construction

- Carton supply

- Controlled carton supply

- Vacuum system

- Vacuum pump included