High viscosity material mixer for bakery and chocolate

Efficiently mix and knead high-viscosity materials for premium chocolate and confectionery products, ensuring consistent texture and quality throughout your production line.

Mixes and Kneads High-Viscosity Ingredients

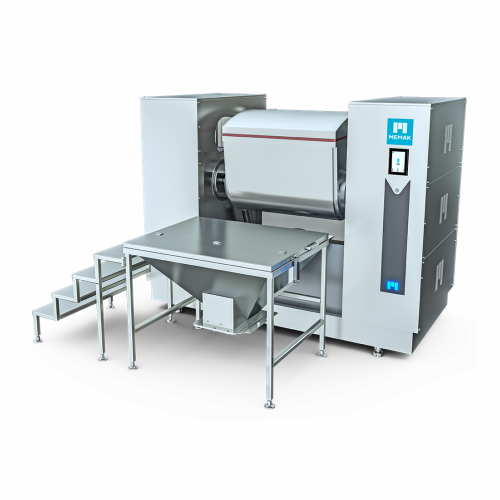

The Z-Mixer MKZM-250 from Memak is engineered for chocolate and confectionery production, specializing in the mixing and kneading of high-viscosity materials. Its twin 11 kW motors provide reliable power for integrating ingredients into a consistent mix, whether creating ganache, pralines, or fudge. With a capacity of 250 kg, it’s ideal for medium-scale production, seamlessly integrating into existing lines. The design caters to manual operations without compromising on efficiency, making it a go-to solution for both chocolate manufacturers and bakery producers. The robust construction ensures durability and ease of maintenance, enhancing overall operational uptime.

Benefits

- Enhances production efficiency by ensuring uniform mixing of high-viscosity materials.

- Reduces operational costs with robust, reliable performance that minimizes maintenance needs.

- Offers flexibility for producing a wide range of confectionery and bakery products.

- Integrates seamlessly into existing production lines for streamlined operations.

- Supports consistent product quality with precise mixing and kneading capabilities.

- Applications

- Confectionery, Sweets, Bakery products, Chocolate, Soft candy

- End products

- Chocolate truffles, Gummy bears, Fudge, Pralines, Caramel swirls, Ganache, Toffee, Jelly beans, Hard candy balls, Chocolate bars, Chocolate chips, Fruit chews, Fondant candies, Marshmallow treats, Nougat centers

- Steps before

- Chocolate Pre-Mixer, Fat Melting, Preparation, Sugar Powder Milling

- Steps after

- Conching, Chocolate Moulding, Tempering, Enrobing, Cooling

- Input ingredients

- high viscosity materials, chocolate ingredients, bakery ingredients

- Output ingredients

- mixed chocolate mass, kneaded dough

- Market info

- Memak is known for manufacturing high-quality, engineered-to-order equipment primarily for the food processing industry, with a reputation for innovation, precision engineering, and reliable customer support.

- Capacity

- 250 kg

- Power of Mixer Motor

- 2x11 Kw

- Total Power

- 22 Kw

- Mixing Function

- Mixing and Kneading

- Viscosity Handling

- High Viscosity

- Batch vs. continuous operation

- Batch

- Mixing and kneading capability

- High viscosity materials

- Automation level

- Manual / Semi-automatic

- Energy efficiency

- 22 kW

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm