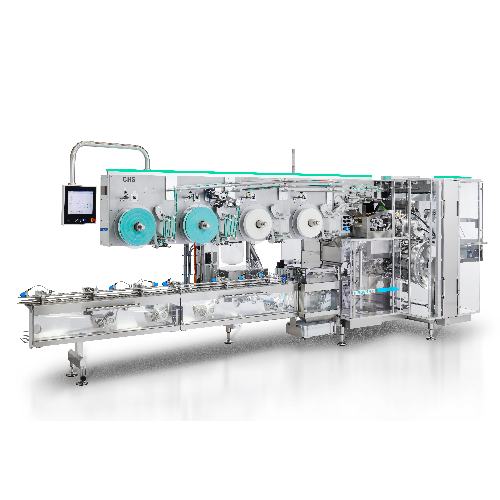

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping solution designed for precision handling and rapid changeovers, ensuring efficient and gentle treatment of diverse sweet and chocolate products.

Wraps and Packs Confectionery Products at High Speed

The CHS packaging machine from Theegarten-Pactec is a state-of-the-art solution for high-speed wrapping of confectionery products. Its modular design facilitates quick changes between wrapping styles and product sizes, catering to a broad range of sweets, chocolates, and candies. Seamlessly integrating into your confectionery production line, the machine operates on a continuous motion principle, ensuring gentle handling of delicate products at speeds of up to 1,800 wrapped items per minute. It efficiently tackles diverse confectionery challenges, wrapping everything from jelly products to truffles in styles like double twist, envelope fold, and foil wrap. The dual-lane feeding system minimizes product damage, while its energy-efficient motor significantly reduces power consumption. With options for stainless steel construction, it supports compliance with food-grade standards and offers easy maintenance and customization to meet specific production needs.

Benefits

- Enhances production efficiency with high-speed operation, wrapping up to 1,800 products per minute.

- Reduces operational costs by minimizing energy consumption through optimized motor control.

- Supports product integrity with gentle handling, reducing breakage and waste.

- Increases flexibility with quick transition between various wrapping styles and product sizes.

- Complies with food safety standards, ensuring hygienic packaging for confectionery products.

- Applications

- Soft caramels, Fudge, Bouillon cubes, Effervescent tablets, Chocolates, Confectionery, Bubble gum, Toffee, Sweets, Cereals, Candies, Jelly products, Eclairs, Chewing gum

- End products

- Chocolate fudge, Gummy bears, Chocolate eclairs, Granola clusters, Pralines, Salted toffee, Mint chewing gum, Mint candies, Chicken bouillon cubes, Nougat-filled chocolates, Fruit-flavored bubble gum, Caramel chews, Truffles, Licorice, Vegetable bouillon cubes, Lollipops, Fruit-flavored effervescent tablets

- Steps before

- Feeding, Product Sorting, Size Selection

- Steps after

- Storage, Distribution, Final Packing

- Input ingredients

- chocolate products, jelly, filled chocolate, enrobed chocolate products, wafers, biscuits, cereals

- Output ingredients

- wrapped chocolate products, wrapped jelly products, wrapped filled chocolate, wrapped enrobed chocolate products, wrapped wafers, wrapped biscuits, wrapped cereals

- Market info

- Theegarten-Pactec is known for its expertise in manufacturing highly specialized packaging machines for small-sized confectionery products, offering innovative, flexible, and efficient solutions tailored to various customer needs in the industry.

- Speed

- 1, 800 wrapped products per minute

- Capacity

- 1, 200 products/min

- Automation

- Continuous motion principle

- Wrapping Styles

- Double Twist, Protected Twist, Top Twist, Side Twist, Vienna-Fruit-Fold, Envelope Fold, Foil Wrap

- Modular Design

- Fast change of product size and wrapping style

- Feeding System

- Two-lane feeding

- Gentle Product Handling

- Ensured by design

- Working mechanism

- Continuous motion

- Changeover time

- Fast due to modular design

- Automation level

- High speed automated wrapping

- Energy efficiency

- Gentle product handling with low energy use

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual or automated options available

- Integration capability

- Flexible integration with feeding and storage systems

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- FDA compliance

- Chocolate packaging materials

- Machine footprint

- Compact modular design

- Control panel type

- Touchscreen PLC

- Discharge method

- Two-lane feeding system

- Wrapping Style Flexibility

- Double Twist, Protected Twist, Top Twist, Side Twist, Vienna-Fruit-Fold, Envelope Fold, Foil Wrap

- Modular Design

- Fast change of product size and wrapping style

- Feeding System Type

- Two-lane feeding

- Wrapping Machine Adaptability

- Equipped for different product types