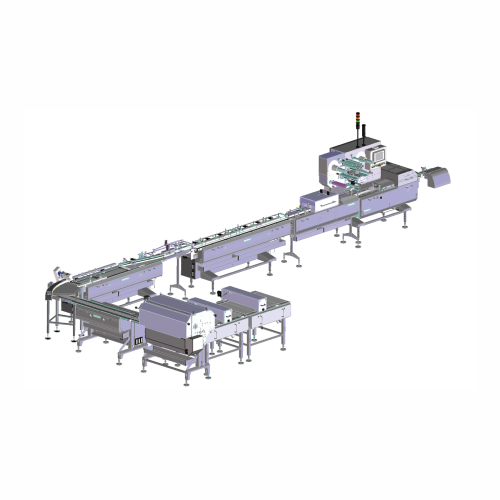

Feeding system for single wrapping lines

Optimize your high-speed wrapping operations by ensuring precise product alignment and seamless integration with upstream and downstream processes, reducing waste and enhancing efficiency in confectionery and snack packaging lines.

Aligns, Transfers, and Monitors Solid Products

The MINISMART from IMA Eurosicma is a belt-based feeding system tailored for single wrapping lines, offering an efficient solution for aligning and transferring solid products such as candy bars, snack bars, and chocolate bars. Its dynamic transfer system accommodates up to 90 rows per minute, ensuring precise monitoring and rejection of defective products through a telescopic system. Ideal for high-speed packaging in the food, dairy, and confectionery industries, it seamlessly integrates with existing operations, thanks to its continuous, automated processes. With no need for changing parts or manual adjustments, the MINISMART simplifies cleaning and maintenance, reducing downtime and enhancing productivity in packaging and transport departments.

Benefits

- Maximizes efficiency by handling up to 90 rows per minute.

- Minimizes defects with precise monitoring and rejection systems.

- Reduces maintenance downtime with tool-free product changeovers.

- Integrates seamlessly into existing high-speed production lines.

- Enhances operational flow with continuous, automated processes.

- Applications

- Sweets, Confectionery products, Food packaged goods, Snacks

- End products

- Nougat bars, Granola bars, Individually wrapped cookies, Snack bars, Wrapped candies, Candy bars, Chocolate bars, Jelly sweets, Energy bars

- Steps before

- Product Alignment, Row Formation

- Steps after

- Wrapping, Defective Product Rejection, Product Transfer

- Input ingredients

- products in rows, aligned products

- Output ingredients

- single wrapping lines, orderly distributed products

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Conveying speed

- Up to 90 rows/min

- Power consumption

- 5.5 kW

- Air consumption

- 50 NL/min

- Standard width

- 800 mm

- Product size range

- Length

- Automation

- Automatic alignment and rejection system

- Product monitoring

- Monitored at every stage of transfer

- Cleaning and maintenance

- Easy cleaning and maintenance

- Product changeover

- No change of parts or manual adjustments required

- Product alignment system

- Dynamic Transfer System

- Product transfer angles

- 90° / 110° / others

- Defective product handling

- Telescopic System rejection

- Product monitoring

- Monitored at every transfer stage

- Cleaning method

- Easy cleaning

- Product changeover

- No changing parts/manual adjustments

- Row throughput

- Up to 90 rows/min

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product alignment

- Aligned rows

- Product size

- Length

- Product handling speed

- Up to 90 rows/min

- Defective product rejection

- Telescopic system

- Machine footprint

- Standard width 800 mm

- Feed/Discharge method

- Belt system

- Transfer system

- Dynamic Transfer System for products alignment

- Exit belt system

- 90° exit belt positioned at the end

- Rejection system

- Telescopic System for the rejection of defective and oversized products

- Integration possibilities

- Dynamic Transfer System, Telescopic System

- Exit belt angle

- 90°/110°/others