Multi-style candy and chocolate wrapper

Achieve high-speed, precision wrapping for diverse confectionery products with versatile fold wrapping capabilities, ensuring seamless integration into your production line and optimized packaging efficiency.

Wraps and Packs Sweets with Precision

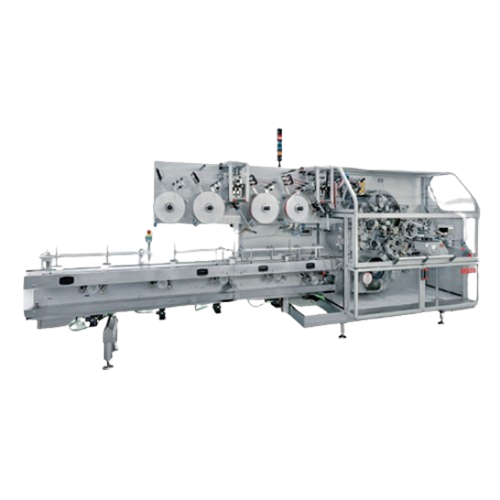

The CW 850 F – M from ACMA is a versatile fold wrapping machine designed for the candy and chocolate production industries. Known for its multi-style wrapping capability, this machine uses a continuous operation system to efficiently handle products like toffees, pralines, and bubble gums. With a throughput of up to 850 pieces per minute, it is engineered to meet the high-speed demands of modern confectionery manufacturing. It utilizes flexible film material, allowing for double twist packaging to accommodate a variety of shapes and sizes. Engineered for integration into existing production lines, the CW 850 F – M features an in-line feeding system and supports quick product changeovers within 1-2 hours, enhancing production flexibility. Built in compliance with EU safety and food regulations, including EN 1672-2 and 2006/42/EC, it ensures safe and hygienic operation. Furthermore, its robust construction is designed for ease of maintenance, facilitating efficient cleaning and minimal downtime.

Benefits

- Maximizes production speed with a capacity of up to 850 pieces per minute.

- Enhances versatility with quick, 1-2 hour product changeovers.

- Ensures regulatory compliance with EU food and safety standards.

- Facilitates seamless integration into existing production lines with in-line feeding systems.

- Minimizes maintenance interruptions with a robust, easy-to-clean design.

- Applications

- Chocolate, Sweets, Candies, Gums

- End products

- Chocolate truffles, Dark chocolate pralines, Bubble gum, Toffee, Fruit chews, Lollipops, Milk chocolate bars, Chewing gum

- Steps before

- Steps after

- Input ingredients

- candies, chocolate, flexible film

- Output ingredients

- wrapped candies, wrapped chocolate

- Market info

- ACMA (Coesia Group) is known for its expertise in designing and manufacturing packaging equipment for consumer goods, focusing on innovative and efficient machinery solutions for markets like confectionery, soap, tea, and coffee, with a strong reputation for reliability and quality.

- Machine speed

- 850 ppm

- Operating mode

- Continuous

- Product changeover time

- 1-2 hours

- Packaging material type

- Flexible film

- Packaging type

- Double twist

- Max product height

- 35 mm

- Min product height

- 5 mm

- Max product length

- 60 mm

- Min product length

- 15 mm

- Max product width

- 30 mm

- Min product width

- 10 mm

- Machine depth

- 1640 mm

- Machine height

- 1900 mm

- Machine length

- 4380 mm

- Machine weight

- 3500 kg

- Feeding system

- Inline

- Working mechanism

- Continuous

- Automation level

- Continuous operation mode

- Product changeover time

- 1-2 hours

- Feeding system

- In line

- Packaging Type

- Double twist

- Flexible film compatibility

- Yes

- Corrosive resistance (e.g.,acids)

- Unknown

- Cleanability

- Yes

- CE marking

- 2014/35/UE

- Safety Regulations

- 2014/30/UE, 2006/42/EC

- Food Regulations

- EN 1672-2-2009

- Environment Regulations

- 640/2009/E

- Machine depth

- 1640 mm

- Machine height

- 1900 mm

- Machine length

- 4380 mm

- Machine weight

- 3500 kg

- Footprint

- Not specified

- Feeding system

- In line

- Integration possibilities

- Yes

- Product changeover

- 1-2 h

- Packaging material compatibility

- Flexible film

- Packaging type options

- Double twist

- Product shape adaptability

- Any flat bottom