Making Compound Chocolate

Find innovative production technology for making compound chocolate and connect directly with world-leading specialists

Compound chocolate is a known alternative for pure chocolate. It uses vegetable fats that are semi-solid at room temperature as an alternative component. Compared to regular chocolates, they can deliver a richer cocoa flavor using practical compound chocolate production methods. It also does not have to undergo tempering due to the natural, glossy texture of vegetable fats.

Technology picks for making compound chocolate

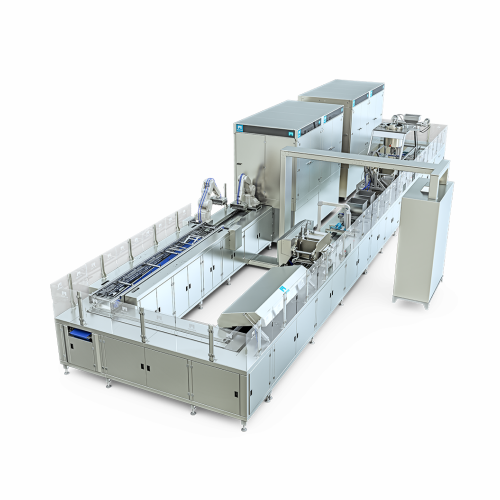

Automatic chocolate processing line

Transform your production by automating the complete chocolate-making process—from prec...

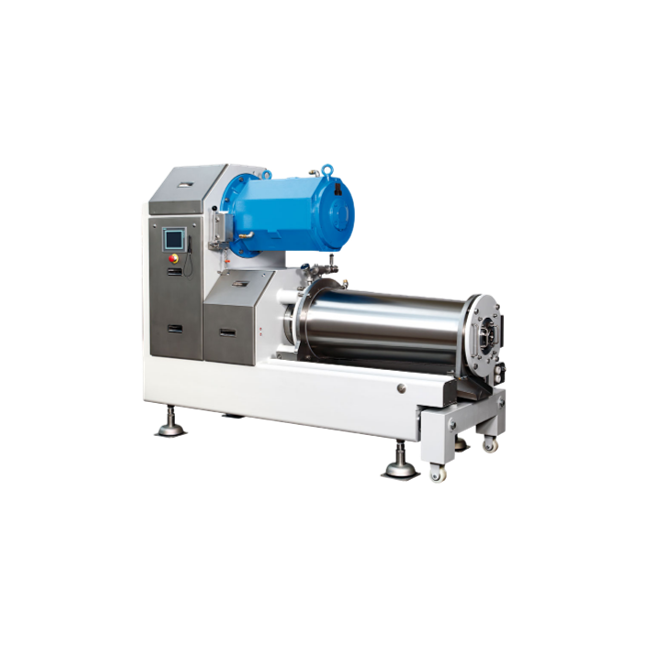

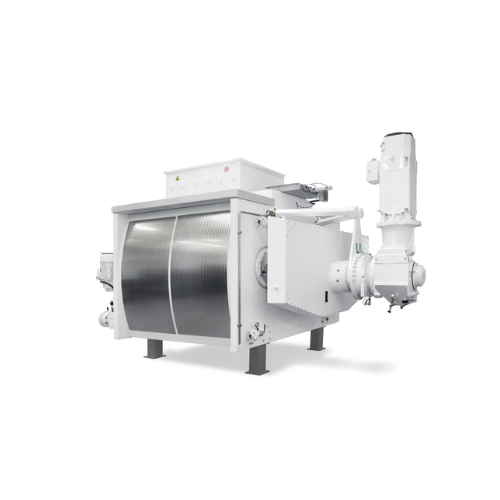

Horizontal ball mill for chocolate refining

Powders of extremely high fineness can be produced with ball mills and agitate...

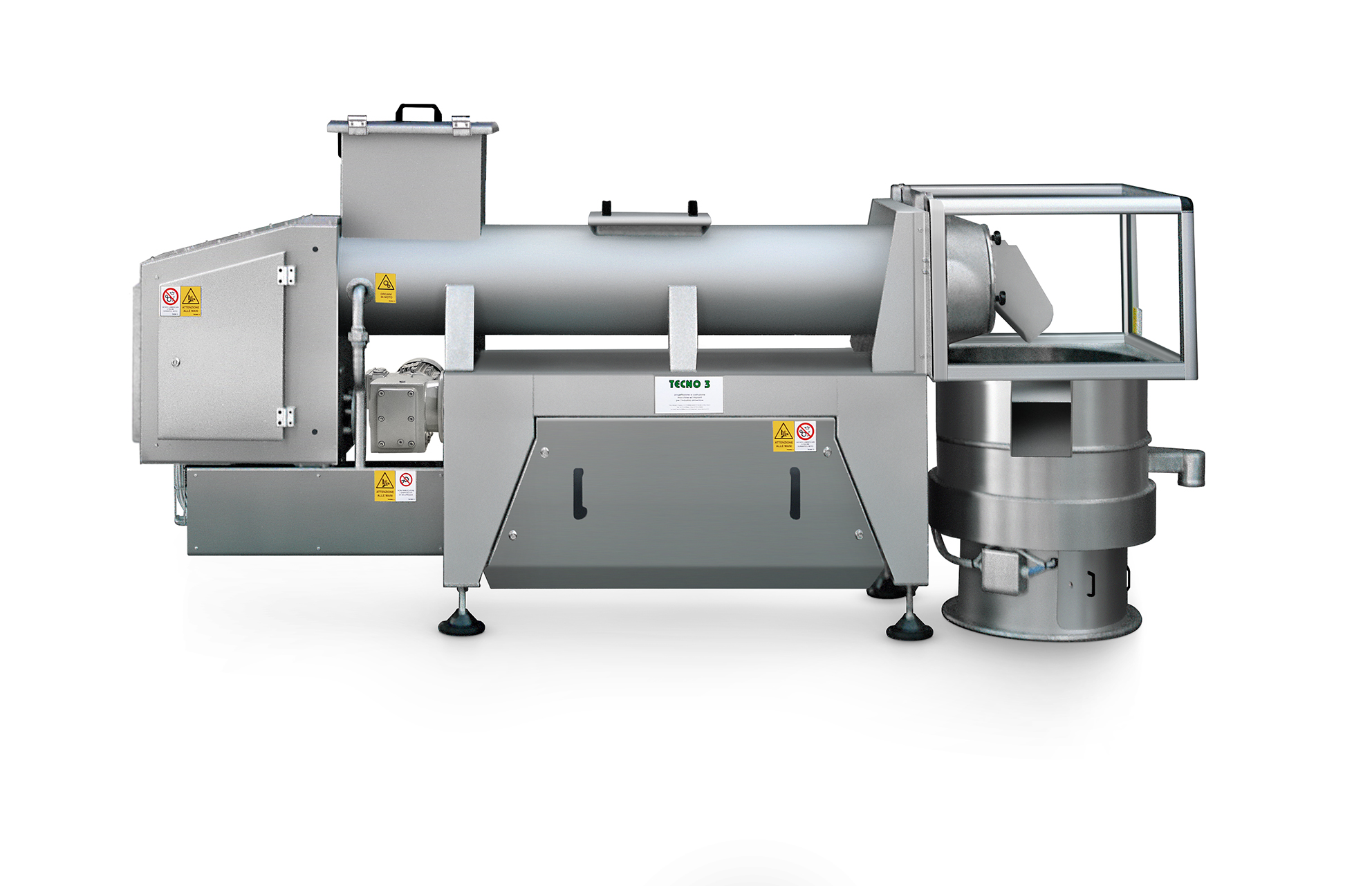

Chocolate processing unit for mixing and grinding

Achieve precise mixing and conching efficiency for premium chocolate an...

Tube heat exchanger for chocolate and cocoa liquor

Achieve precise temperature control for chocolate and cocoa processing...

Tell us about your production challenge

Compound chocolate vs. couverture chocolate

Compared to compound chocolate, couverture chocolate is the highest grade of chocolate available in the market. For a chocolate to be couverture, it must contain a minimum of 35% cocoa solids and 31% cocoa butter. In terms of ingredients, you make compound chocolates using cocoa powder and vegetable oil. Couverture chocolate, in their turn, use cocoa butter and chocolate liquor. You need to conch couverture chocolate more deliberately, due to the high-fat content. It also needs to go through tempering – where it heats to an optimal temperature of 29-32 °C (84.2-89.6 °F) for beta crystals to grow and then cools down to 20 °C (68 °F). Compound chocolate processing does not involve tempering and is more manageable in terms of resources.

Is compound chocolate ‘true’ chocolate?

No. It is only an alternative to true chocolate – which contains cocoa solids, cocoa butter, and dairy fat – by US standards. However, EU regulations allow up to 5% of vegetable fats to be present in true chocolates. In general, the chocolate standards-of-identity requires chocolate to contain 50-60% cocoa butter and should exclusively use cocoa liquor. Any deviation from these standards becomes a compound coating or compound chocolate. Cocoa butter replacers or CBRs are also used as an alternative to cocoa butter. Their consistency makes it easy to mix with chocolate liquor. However, their tolerance to other fats is only up to 20%.

Who will buy compound chocolates?

Compound chocolate production usually serves for coating candies. Compound chocolate hardens more easily than normal chocolate. This is because it has vegetable fats as ingredients, and they don’t require much tempering, which means it’s easy to mold them to candies and other desserts. True chocolate needs tempering to harden properly.

It also serves confectionaries and bakeries that involve dipping food items in chocolate, such as chocolate-dipped strawberries and biscuits. Compound chocolates are a reliable alternative for couverture chocolate to use in chocolate fountains. They are also a practical choice for large servings of chocolates, such as caterers, restaurants, and other dessert businesses. Though the flavor and melt-in-mouth sensation are not the same as pure chocolate, it is still a cost-effective substitute and is relatively easy to work with.

Healthy cocoa butter alternatives for compound chocolate production

Usually, CBEs (Cocoa Butter Equivalent) and CBAs (Cocoa Butter Alternatives) are using vegetable oils with hydrogenated fat or trans-fat. They emulate cocoa butter and increase the shelf life of compound chocolates. This can, in turn, leads to major health issues, such as raised cholesterol levels, and can further develop stroke or heart disease. There is however an alternative to this, which is non-hydrogenated fat. Most food companies now use this kind of fat in their dairy products such as chocolates. Lauric fats, which are ingredients of CBEs, do now have non-hydrogenated fat alternatives.

Processing steps involved in compound chocolate making

Which compound chocolate technology do you need?

Chocolate tempering quality analyzer

Ensure your chocolate’s tempering precision with a device that accurately assess...

Chocolate moulding system for small-scale production

Optimize your chocolate production by efficiently melting, tempering...

Batch tempering solution for chocolate production

Achieve precise temperature control for chocolate consistency and quali...

Industrial chocolate flaking system

Achieve precise chocolate flake dimensions effortlessly, enhancing product textures and...

Automatic one-shot moulding line for chocolate production

Streamline your chocolate production with a versatile line tha...

Conching solution for chocolate processing

Achieve optimal chocolate texture and flavor by ensuring efficient conching, cr...

Automatic chocolate shell moulding line

Enhance your production capabilities with a cutting-edge moulding line that deliver...

Enrobing system for high-quality chocolate applications

Enhance your confectionery line with precise chocolate coating ca...

Inline chocolate filter for large particle removal

Ensure the purity and consistency of your chocolate products by effici...

Commercial chocolate refiner/conche

Elevate your chocolate production with a versatile 5-in-1 solution, integrating cocoa m...

Chocolate pump for confectionery production

Effortlessly pump and convey a range of chocolate-based products with precisio...

Chocolate storage tank for large-scale manufacturing

Enhance your chocolate production line with a storage system designe...

Pre-refiner for chocolate processing

Optimize pre-refining in chocolate and cocoa production with precise fineness control,...

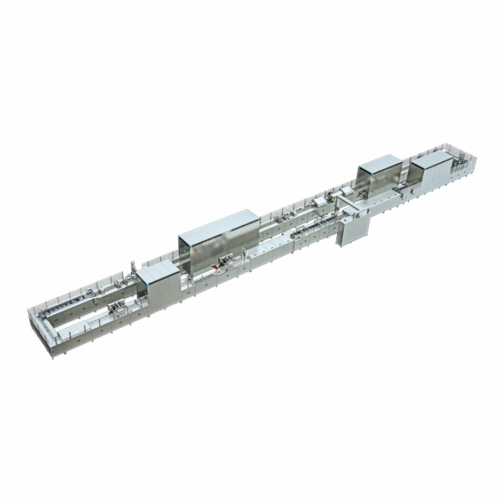

Fully automatic chocolate processing line

Accelerate your chocolate and confectionery production with this high-speed syst...

Chocolate processing unit for mixing, grinding, and conching

Optimize chocolate production with precise mixing, grinding...

Laboratory conching solution for small batches of chocolate

Optimize your chocolate formulations with precise moisture a...

Automatic chocolate processing line

Transform your production by automating the complete chocolate-making process—from prec...

Ball mill for chocolate, cocoa, and nut products

Optimize your grinding processes and achieve perfect product consistency ...

Double-overthrow conche for chocolate production

Achieve precise taste and texture in chocolate production with reduced en...

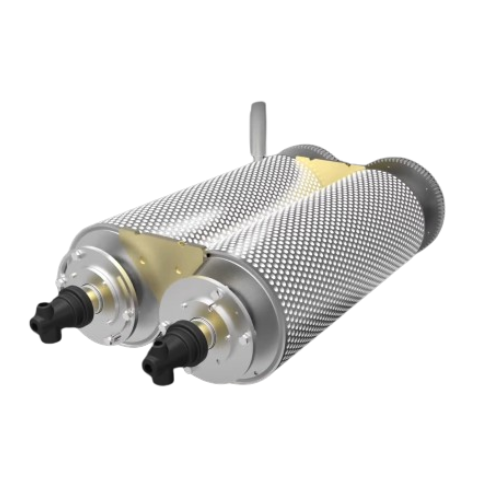

Five-roll refiner for chocolate production

Achieve precise particle size control and energy efficiency in your chocolate r...

Chocolate production belt line

Optimize your chocolate and bakery production with a versatile belt line designed for continu...

Chocolate moulding line for lentils, balls, and eggs

Achieve precision and efficiency in molding chocolate centers for le...

Flexible chocolate moulding line for limited space production

Optimize your production line with a versatile moulding sy...

Chocolate tempering system

Optimize your chocolate production with a tempering system that achieves precise crystallization,...

Lab-scale chocolate chip depositor

Enhance your R&D capabilities with precision depositing of chocolate masses, allowi...

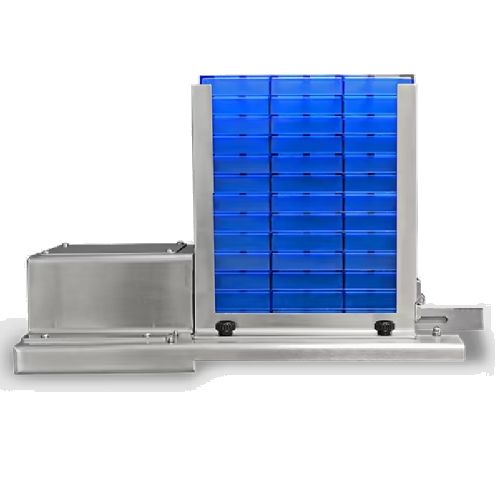

Chocolate quality analysis instrument

Ensure the highest quality of your chocolate production by precisely measuring contra...

Chocolate temper measurement device

Ensure your chocolate maintains optimal temper by measuring and analyzing the chocolate...

Cooling simulator for chocolate production optimization

Optimize your chocolate cooling processes and refine production s...

Laboratory cold-press chocolate shell maker

Enhance your R&D capabilities with a solution that enables precise cold-p...

Energy efficient chocolate tempering solution

Enhance your chocolate products with precise temperature control, reducing e...

Laboratory chocolate tempering solution

Achieve precise tempering of diverse chocolate and confectionery masses with optimi...

Small-scale chocolate enrober for laboratory use

Optimize small-scale chocolate production with a flexible enrober designe...

Depositing system for solid and filled chocolates

Enhance your chocolate production with a versatile depositing system, p...

Enrobing system for rapid changeover in confectionery production

Achieve seamless chocolate coating transitions with a s...

Cooling unit for chocolate mass extrusion

Optimize your chocolate production by precisely cooling chocolate masses during ...

Industrial melting tank for chocolate and confectionery production

Maximize your production efficiency by seamlessly in...

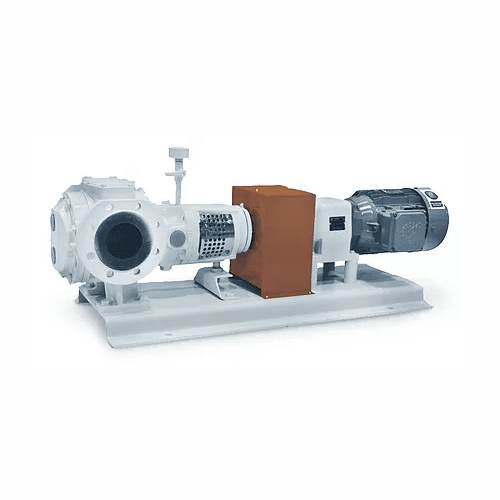

Chocolate pump for consistent mass transport

Efficiently transport chocolate mass with precision, ensuring gentle handling...

Small scale chip depositor for confectionery production

Efficiently deposit a variety of confectionery and snack products...

Aeration and aroma mixing system for chocolate production

Optimize your chocolate and confectionery production with prec...

Robotic chocolate assortment system

Streamline your chocolate production by precisely assorting various filled chocolate ar...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Professional chocolate tempering system for chocolatiers

Achieve precise chocolate tempering with advanced digital contro...

Automatic chocolate mould loader

Streamline your chocolate production with seamless mould loading, optimizing efficiency in ...

Professional chocolate tempering system for artisan chocolatiers

Achieve precise chocolate tempering with quick changeov...

Industrial chocolate conching solution

Optimize chocolate production by effectively removing acidity and moisture, ensuring...

Melting mixer for bean to bar chocolate production

Achieve seamless chocolate texture and remarkable flavor enhancement w...

Flowpack packaging machine for chocolate products

Effortlessly wrap and preserve large quantities of chocolate and sweet ...

Professional chocolate tempering equipment for efficient production

Enhance your production capabilities with a versati...

Carton Tray Forming Machine for Biscuits

Trays used as packaging for products for biscuits, cookies, chocolates and other s...

Mixer for production of chocolate with inclusions

Using the same mixing equipment for different recipes in chocolate manu...

Refining plant for chocolate

Achieving a balanced, velvety mouthfeel in chocolate is challenging. Larger particles in chocol...

Industrial melter for chocolate rework

Wastage or out-of-specification products are not uncommon in the chocolate manufactu...

High-speed chocolate block melt machine

If you produce chocolate using larger blocks instead of cocoa beans, chocolate melt...

Entry level cocoa roaster

The biggest challenge that small-scale cocoa processing manufacturers face is even and thorough ro...

Small capacity cocoa grinder

The first step of producing almost any kind of chocolate starts with grinding cocoa beans to ge...

Entry level bean to bar line

One of the challenges when setting up a small-scale cocoa processing factory is making all of t...

Small capacity chocolate melangeur

In order to produce the finest of chocolate products, you need the cocoa nibs to be grin...