Making Cocoa Butter

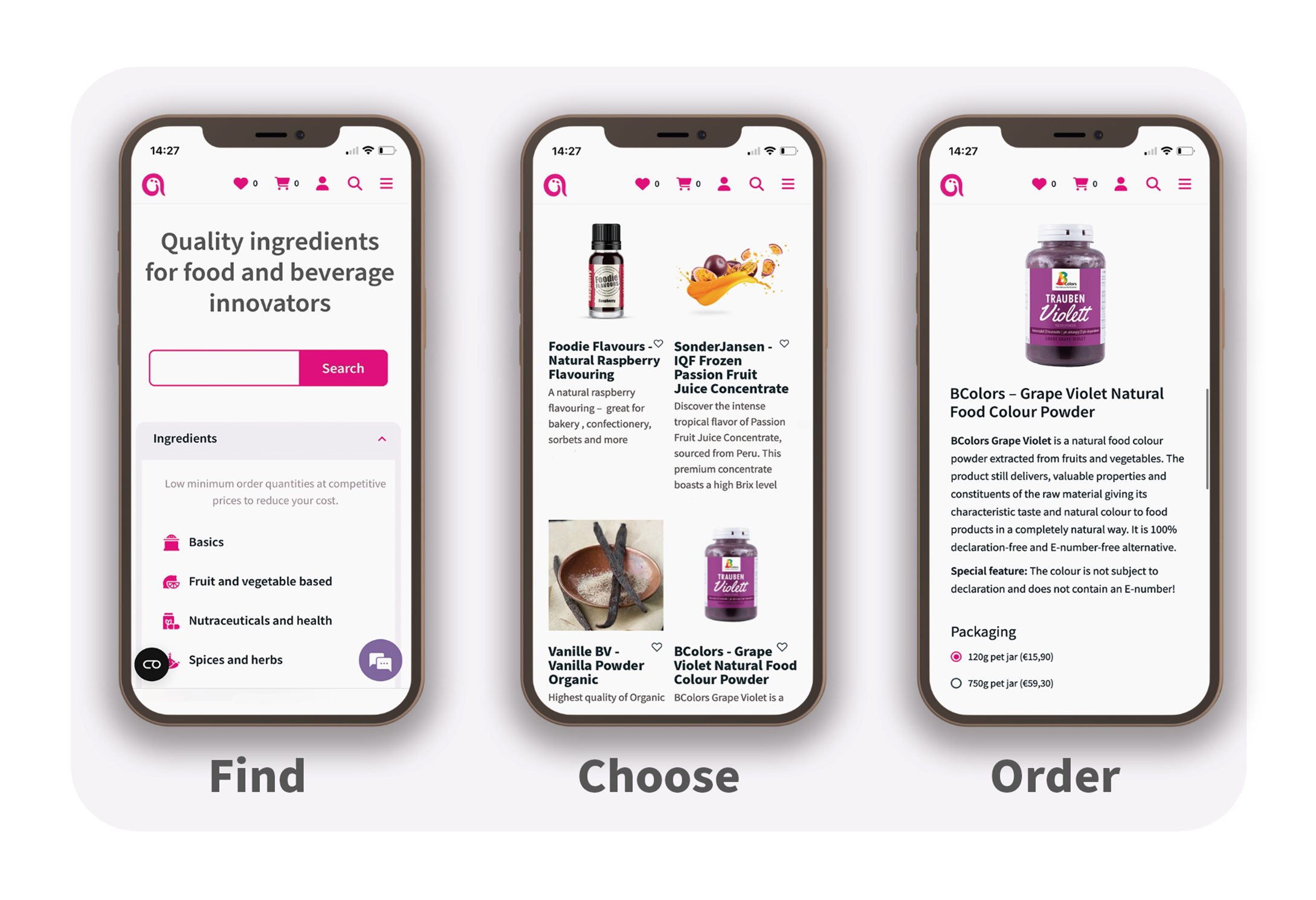

Find innovative production technology for making cocoa butter and connect directly with world-leading specialists

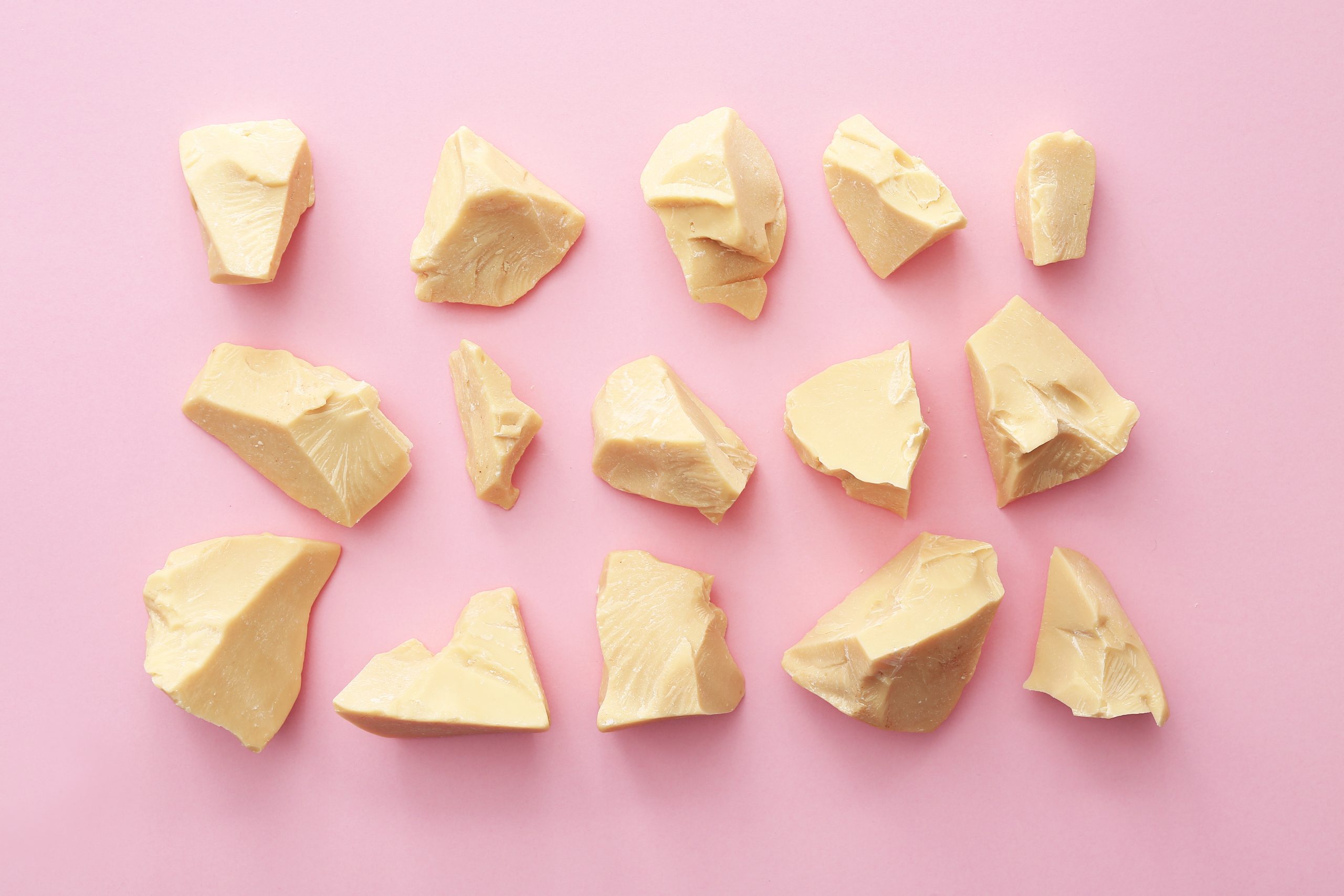

Cocoa butter is the fat product of cocoa liquor. It is an integral part of the chocolate-making process. To make cocoa butter, roast and process cocoa beans with the help of a cocoa butter production machine. After that, it undergoes continuous crushing – forming a rich liquid, known as cocoa liquor. You can finally press the liquid to extract cocoa butter.

Technology picks for cocoa buter

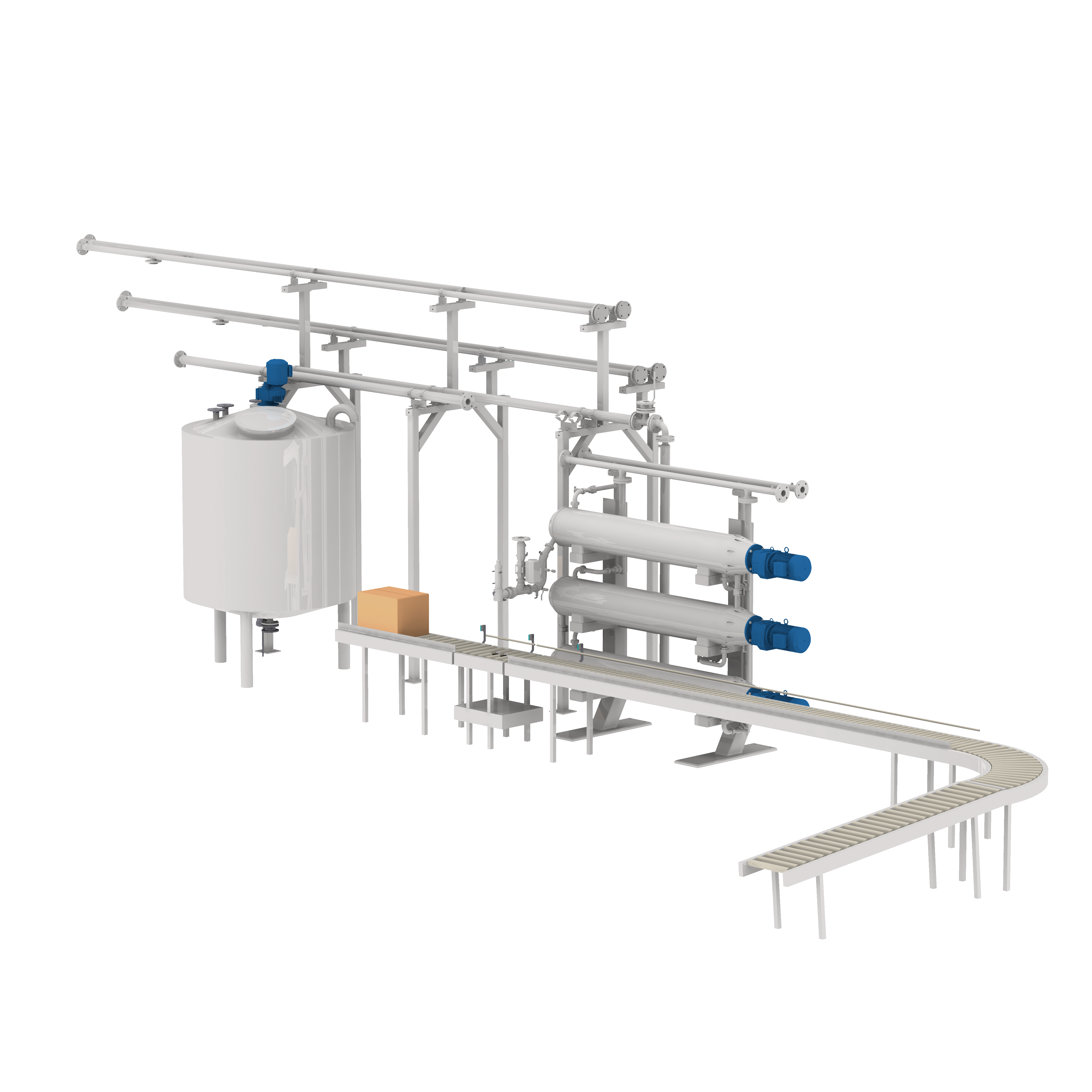

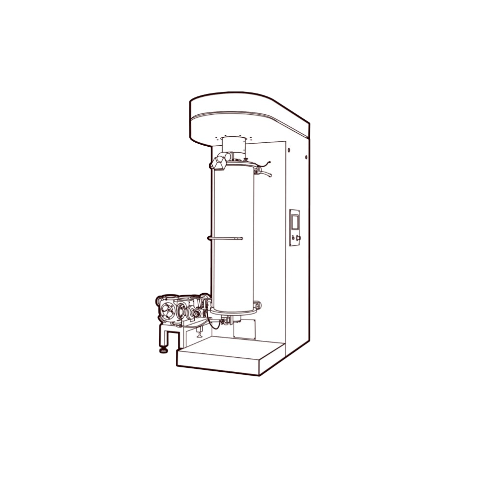

Cocoa butter and cocoa liquor melting unit

Optimize your chocolate production with a unit designed for efficient melting a...

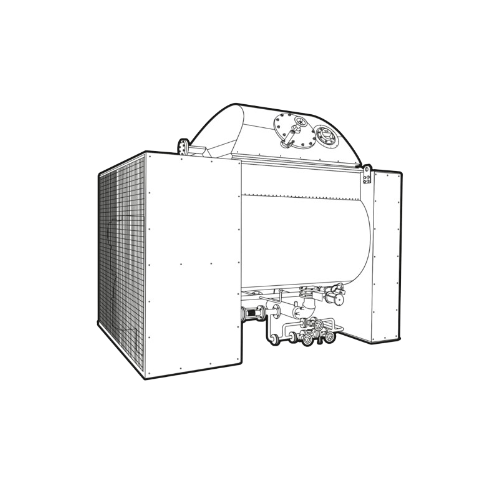

Cocoa butter deodorization system

Achieve premium cocoa butter quality with minimal thermal impact using a unique deodoriza...

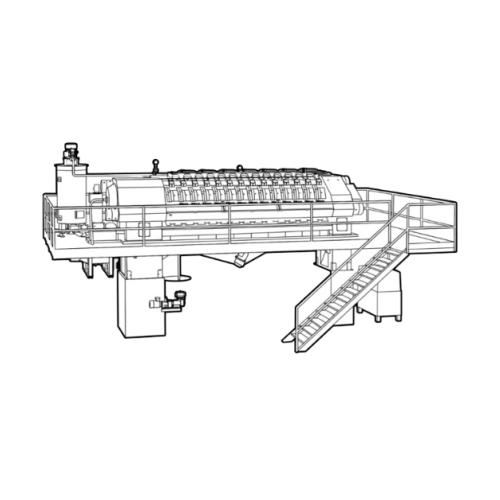

Cocoa butter filter-liquor blocking line

Cocoa butter, when pressed, is never totally free of solids. The process requires ...

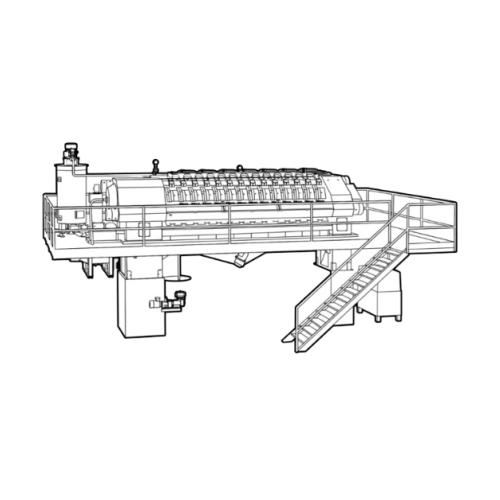

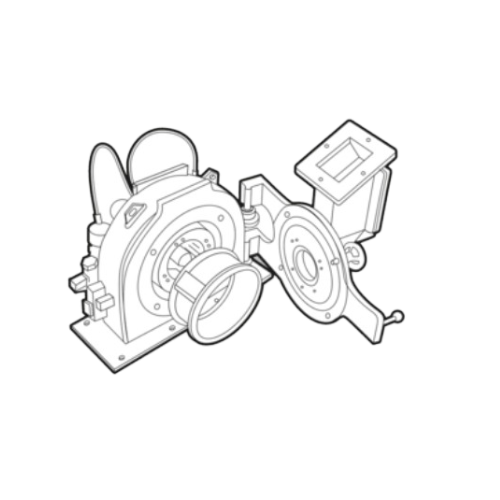

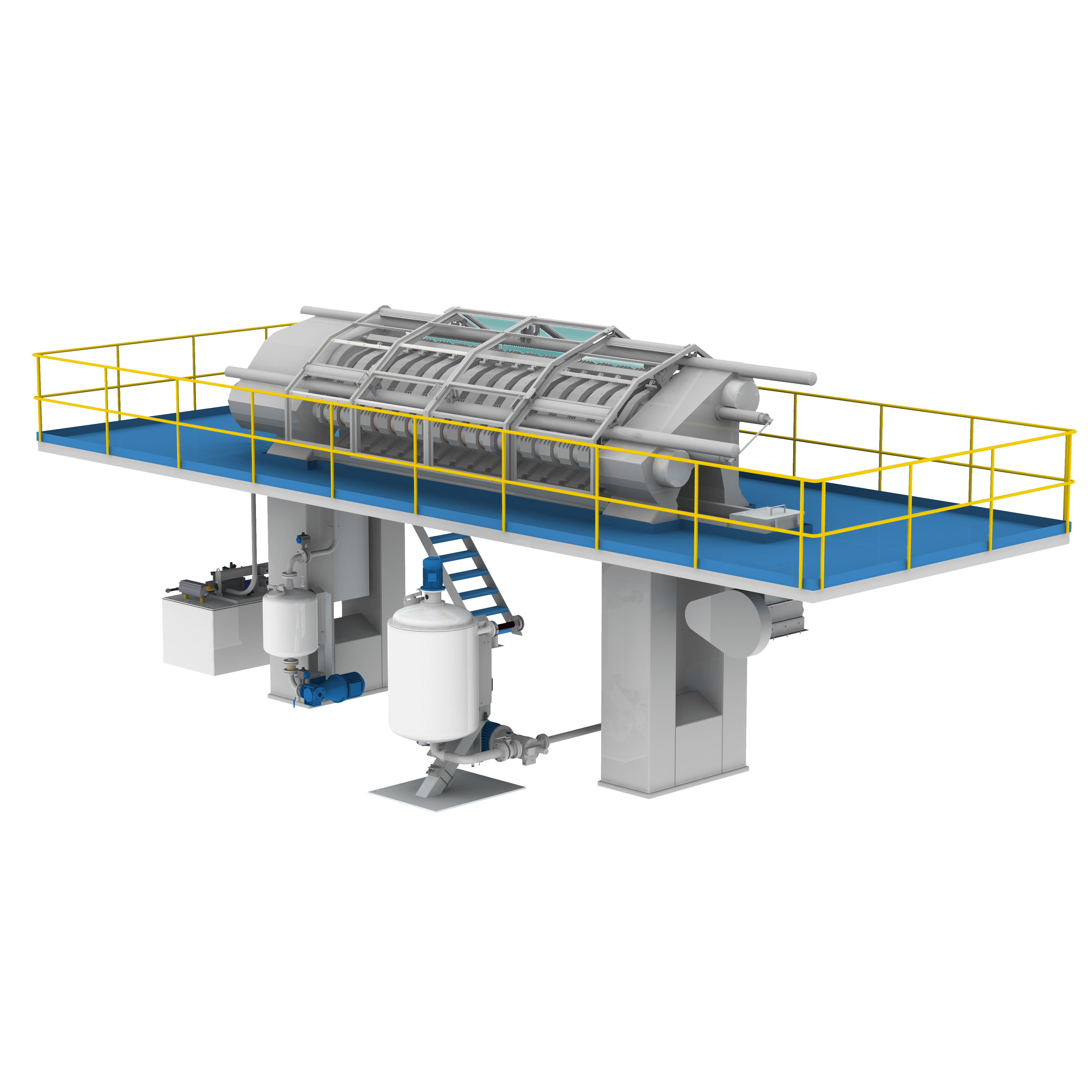

Cocoa pressing plant for high-capacity cocoa liquor processing

Optimize your cocoa processing by converting cocoa liquor...

Stories about cocoa butter

Tell us about your production challenge

Key processes and utilization of cocoa butter production machines

In chocolate production, cocoa butter originates from cocoa nibs, which you first alkalize to develop flavor and color. Next, they undergo milling to produce cocoa liquor and pass through a mechanical press to extract the cocoa butter in its solid form. Cocoa butter making machines such as a cocoa butter hydraulic press make this process easier. Cocoa butter processing machines can also help in producing filtered cocoa butter in its liquid form. Also, producers typically deodorize cocoa butter for chocolate production, through a process called deodorization. They do it to emit reactive components of the cocoa butter, which may cause off-odors.

Cocoa butter applications and in-market audiences

Other than making chocolate, cocoa butter also is used in various industries. In pharmaceuticals, manufacturers make cocoa butter odorless and tasteless through steam and vacuum extraction. They eliminate all volatile compounds and organic impurities, leaving a clear texture and appearance in the ingredient. Cocoa butter also possesses natural antioxidants and has many health benefits. In the cosmetics industry, lotions, soaps, creams, hair products, and many more products use cocoa butter as an ingredient. It reduces the effects of hair loss, aging, skin inflammations, and scars.

Environmental impacts of cocoa butter production

As the global demand for cocoa butter continuously grows, manufacturers from different industries are encouraged to develop a traceable supply chain, which oversees the production process from start to finish. For instance, they document and trace all raw materials to ensure that they comply with the global industry standards. This also promotes accountability and ensures that raw materials are well taken care of, as well as efficient logistics for the final products. Farmers also learn Good Agricultural Practices and other related training to combat any environmental and socioeconomic challenges.

Standards for a great quality cocoa butter

Good cocoa butter should contain at least 60% saturated fat. It also contains other natural fats. Organic cocoa butter has a pale yellow color, smooth texture, and a pleasant cocoa aroma. Taste-wise, it has a strong cocoa flavor, which makes it hard to imitate when finding alternatives. Considered fat substitutes are coconut, palm rapeseed, and shea butter. Although this happens in pharmaceutical or cosmetic purposes only, since chocolate standards are strict for both US and EU.

Processing steps involved in cocoa butter making

Which cocoa butter technology do you need?

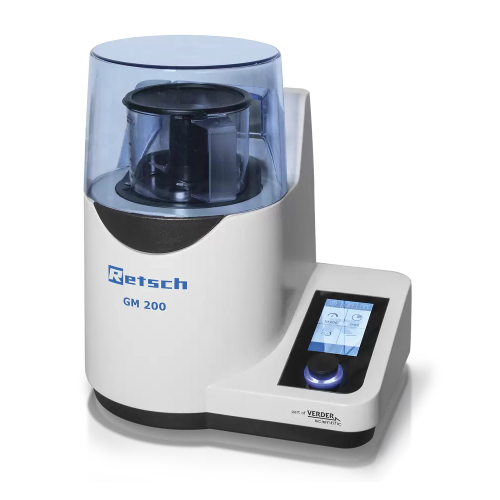

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Turbo block flaker for fats

Achieve quick and precise flaking of chocolate, cocoa butter, and fats with high-speed technolog...

Industrial chocolate flaking solution

Optimize your confectionery production with high-speed flaking technology, ensuring p...

Melting and mixing kettles for chocolate production

Achieve consistent melting and mixing of chocolates, butter, and jams...

Chocolate melter for large quantities

Efficiently melt and maintain the temperature of substantial chocolate quantities wit...

Turbo block flaker for cacao butter

Efficiently transform large chocolate and fat blocks into uniform flakes, enhancing pro...

Semi-liquid weigh filler for edible oils & fats

Achieve precise weigh filling of semi-liquids while minimizing product was...

Automated bag sealing for packaging lines

Enhance your packaging efficiency by seamlessly integrating an automated bag sea...

Automatic bag sealer for varied box sizes

Seamlessly integrate this high-speed bag sealing solution to enhance productivit...

Oil and fat filling system for industrial use

Optimize your production line with this precise filling solution, designed t...

Cocoa butter and cocoa liquor melting unit

Optimize your chocolate production with a unit designed for efficient melting a...

Jet mill for toner and pigment industries

Optimize particle size and distribution for high-demand applications with this h...

Mechanical conveying systems for bulk solids

Optimize your bulk material processes with advanced mechanical conveying syst...

Heavy-duty shredder for difficult materials

Struggling with stubborn materials that resist conventional shredding? This ro...

Ultrafine classifier for precise particle separation

Gain precise control over particle size with this ultrafine classifi...

Discharge systems for difficult bulk materials

Achieve seamless bulk material discharge with our advanced systems that eff...

Ball mill for dry comminution of hard materials

Achieve ultrafine particle sizes and precise material breakdown with this ...

Cocoa pressing plant for high-capacity cocoa liquor processing

Optimize your cocoa processing by converting cocoa liquor...

Cocoa sterilizing and alkalizing plant

Optimize cocoa product quality with a system engineered for precise sterilizing, alk...

Batch conche for chocolate making

Achieve optimal texture and flavor development in your chocolate with precise control ove...

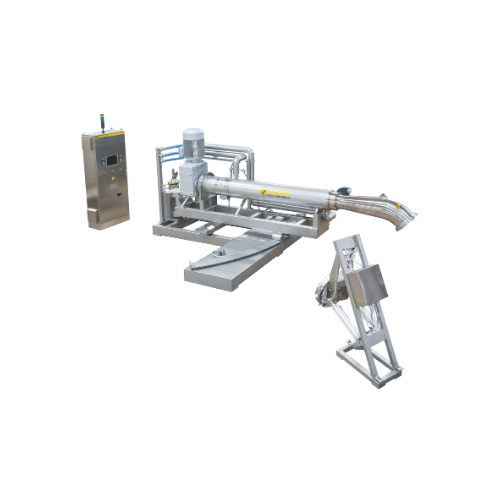

Inline cocoa bean roaster

Streamline your cocoa production by achieving consistent roast quality with precision heat control...

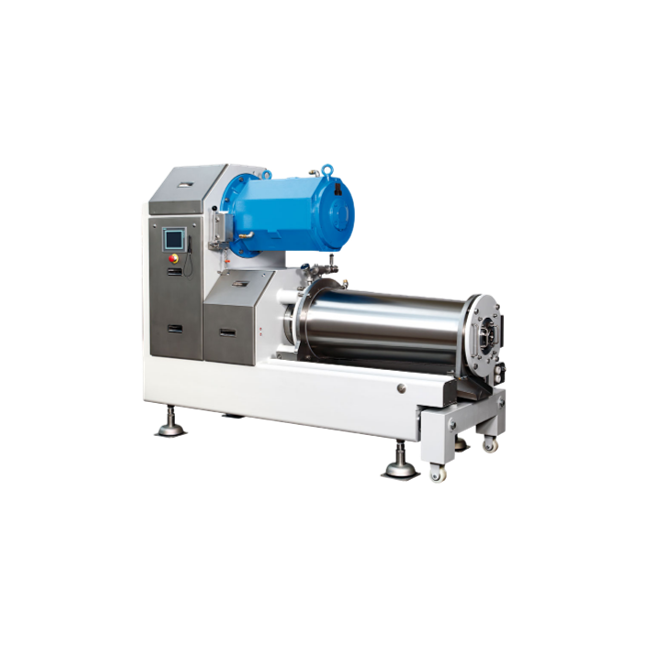

Pre-refiner for chocolate processing

Optimize pre-refining in chocolate and cocoa production with precise fineness control,...

Chocolate refiner and conche solution

Elevate your chocolate production with a versatile solution that seamlessly integrate...

Spindle mill for fine and super fine grinding of cocoa liquor

Achieve precision in grinding cocoa liquor and nut pastes ...

Industrial melting unit for chocolate and powders

Enhance your production efficiency by seamlessly melting and homogenizi...

Stainless steel chocolate tank for storage and processing

Efficiently control temperature and consistency for chocolate ...

Oscillating heat exchanger for gelatin production

Ensure hygienic transfer in gelatin production with an innovative oscil...

Pin worker unit for margarine plasticizing

Ideal for high-speed continuous operations, these pin worker units ensure optim...

Cleaning-in-place system for oils and fats

Streamline your production line by efficiently cleaning oils and fats processin...

Cocoa butter deodorization system

Achieve premium cocoa butter quality with minimal thermal impact using a unique deodoriza...

Scraped surface heat exchangers for gelatine processing

Effortlessly manage the cooling, gelling, and extrusion of gelati...

Process tanks for oils and fats

Optimize your oil and fat processing with versatile tanks designed for precise emulsificatio...

Scraped surface heat exchanger for oils and fats

Achieve precise crystallization and streamline the production of margarin...

Powder addition system for oils and fats

Efficiently integrate powdered additives into your liquid processes with our hygie...

Scraped surface heat exchanger for viscous liquids

Optimize heating and cooling of viscous liquids efficiently with conti...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Scraped surface exchanger for heat transfer with high viscosity

Efficiently handle high-viscosity products and extend ma...

Filling and weighing station for chocolate production

Ensure precise and efficient chocolate mass depositing with a stati...

Industrial block melt system for butter and chocolate

Efficiently transition solid blocks of butter, chocolate, or waxes ...

Spray cooler for food and chemical industry applications

Achieve precise particle size control and encapsulation for melt...

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

Cocoa bean processing line from cocoa pod to cocoa nibs

Streamline your cocoa production process by transforming raw coco...

Chocolate tempering solution for superior gloss and shelf life

Achieve consistent sheen and extend the shelf life of cho...

Industrial cocoa nib grinder for bean to bar production

Streamline your chocolate production with this versatile grinder,...

Entry level cocoa roaster

The biggest challenge that small-scale cocoa processing manufacturers face is even and thorough ro...

Small capacity cocoa grinder

The first step of producing almost any kind of chocolate starts with grinding cocoa beans to ge...

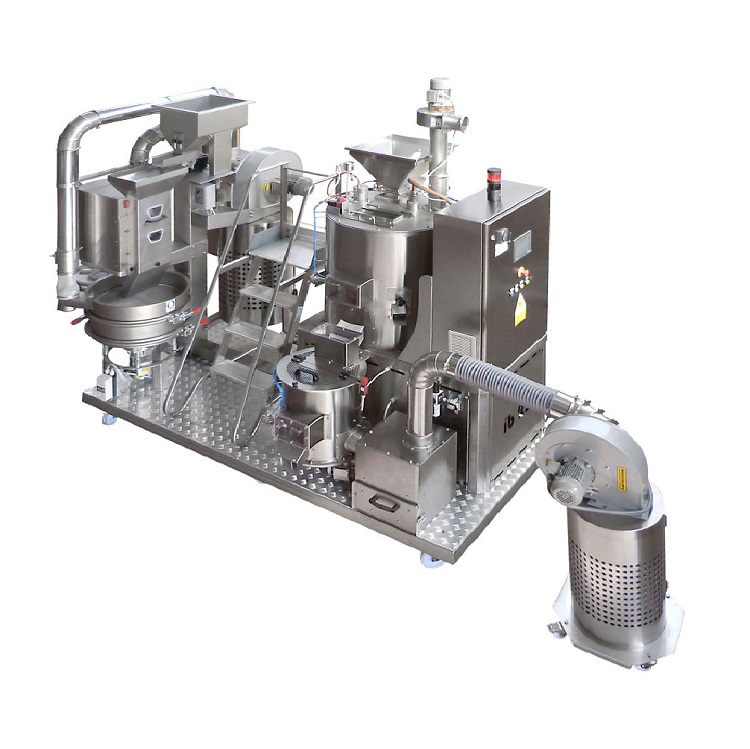

Entry level bean to bar line

One of the challenges when setting up a small-scale cocoa processing factory is making all of t...

Chocolate laboratory ball mill

The ball mills are a type of grinder, with a cylindrical shape, used in the process of grindi...

Continuous cocoa bean roasting line

When you are processing chocolate, after the conditioning and fermenting of cocoa, the ...

Infrared rotating drum dryer

Traditional drying methods are often slow and can actively damage ingredients, reducing the fin...

Small scale cocoa beans processing machine

For the highest quality chocolate production, complete control of the entire pr...

Entry level bean-to-bar machine

The production of high-quality chocolate from the bean can often be out of the reach of smal...

R&D roaster for cocoa beans

When designing a new chocolate line or experimenting with new ingredients for existing processes...

Ball roaster for cocoa beans

Homogeneous roasting of cocoa beans is essential for the production of fine chocolate. Precise ...

Cocoa powder processing line

Cocoa beans are first fermented, dried, roasted, and separated from their skins to obtain a coc...

Cocoa press

After the cocoa beans have been fermented, dried, roasted, and separated from their skins, you obtain a cocoa mass...