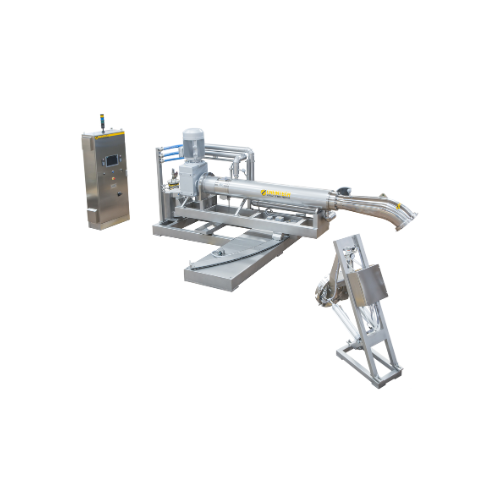

Oscillating heat exchanger for gelatin production

Ensure hygienic transfer in gelatin production with an innovative oscillating heat exchanger, designed to seamlessly integrate into your processing line while optimizing heat exchange and drying processes.

Processes and Transfers Gelatin Efficiently

The Oscillating Chemator Heat Exchanger, offered by Chemtech, is specifically designed for efficient gelatin production. It features an oscillating base frame that ensures hygienic transfer of gelatin noodles to dryer belts. With the capability to process up to 2,000 kg/hr, it is ideal for producing gelatin sheets and powders. Integrated with automatic wash-out plate systems and CIP technology, it simplifies cleaning while ensuring compliance with food safety standards. It operates within a fully automated SCADA control system to maintain high-speed processing and optimal operational efficiency. Constructed for durability, it offers glycol refrigeration for energy-efficient temperature control, making it indispensable for food processing and gelatin production lines.

Benefits

- Enhances hygiene standards with oscillating transfer, minimizing contamination risks.

- Maximizes production efficiency, processing up to 2,000 kg/hr.

- Reduces energy costs through glycol refrigeration system.

- Facilitates quick and thorough cleaning with CIP technology.

- Ensures consistent and reliable operation with full SCADA automation.

- Applications

- Cocoa butter, Gelatine, Shortening (bakery and pastry), Oils and fats, Margarine

- End products

- Cooking oils, Shortening for pastries, Vegetable fats, Gelatin powder, Cake shortening, Gelatin sheets, Margarine blocks

- Steps before

- Purification, Emulsification

- Steps after

- Drying, Packaging

- Input ingredients

- gelatine noodles

- Output ingredients

- dried gelatine noodles

- Market info

- Capacity

- up to 2, 000 kg/hr

- Automation

- SCADA control systems and full automation

- Cleaning method

- CIP systems

- Working mechanism

- Oscillating base frame

- Flow type

- Continuous

- Automation level

- Full automation with SCADA control systems

- Cleaning method

- CIP (Clean-In-Place)

- Integrated steps

- Chemetator heat exchangers, Hygienic high pressure feeding pump

- Base frame

- Oscillating

- Discharge method

- Noodles to dryer belt

- Capacity

- Up to 2000 kg/hr

- Control panel type

- SCADA

- Control panel type

- SCADA control systems

- Integration possibilities

- Full automation

- Base frame type

- Oscillating base frames