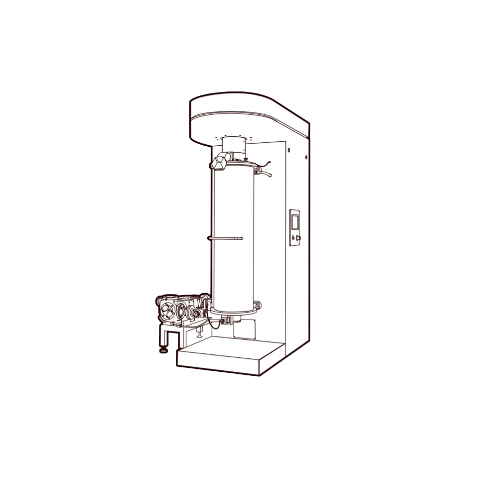

Spindle mill for fine and super fine grinding of cocoa liquor

Achieve precision in grinding cocoa liquor and nut pastes with this continuous high-speed mill, ensuring optimal texture and consistency for premium confectionery and food products.

Processes Cocoa and Nut Pastes Continuously

The Spindle Mill HKM from Hamburg Dresdner Maschinenfabriken is engineered for the precise fine and super fine grinding of cocoa liquor, nuts, and tahina. This continuous working mill optimizes production lines with its innovative design, combining pressure, friction, and shear forces. Designed for cocoa processors and nut paste producers, it efficiently handles products like almond butter, chocolate, and hummus. It features throughput levels of up to 2000 kg/h, driven by an advanced PLC-controlled system for seamless integration into your operations. The wear-resistant stainless steel construction, reversible grinding pot, and automatic temperature control enhance both durability and product consistency. The HKM conforms with EU machinery guidelines, ensuring compliance while providing energy efficiency with reduced cooling and warm water consumption. For added flexibility, it integrates easily with complementary equipment such as the Beater Blade Mill SMM. Enjoy the advantage of Hamburg Dresdner’s robust engineering support for all customization needs.

Benefits

- Enhances production efficiency with continuous operation and high throughput capabilities.

- Maintains consistent product quality through precise temperature control.

- Reduces maintenance costs with durable, wear-resistant construction.

- Minimizes energy usage with optimized cooling and heating systems.

- Ensures seamless integration and flexibility in manufacturing lines with PLC-controlled operation.

- Applications

- Tahina, Snacks, Cocoa liquor, Sweets, Nuts, Spices, Nut paste

- End products

- Cocoa butter, Hummus, Spice blends, Tahini, Peanut butter, Nut spreads, Almond butter, Chocolate, Nut-based snacks, Cocoa mass, Hazelnut spread

- Steps before

- Pre-Treating, Winnowing, Roasting, Pre-Grinding

- Steps after

- Pressing, Mixing, Pre-Refining

- Input ingredients

- preground cocoa liquor, tahina, nut paste, similar goods

- Output ingredients

- fine cocoa liquor, super fine cocoa liquor, fine tahina, super fine tahina, fine nut paste, super fine nut paste

- Market info

- Hamburg Dresdner Maschinenfabriken GmbH is known for expertise in manufacturing industrial machines for the cocoa, chocolate, and confectionery industries, particularly focusing on roasting, grinding, and refining processes. They have a strong reputation for quality and innovation.

- Capacity

- Up to 2000 kg/h

- Throughput

- Up to 1250 kg/h (HKM 80), Up to 2000 kg/h (HKM 200)

- Grinding pot filling content

- 80 L (HKM 80), 200 L (HKM 200)

- Connected Load

- 47 kW (HKM 80), 92 kW (HKM 200)

- Cooling water consumption

- Approx. 0.7 m³/h (HKM 80), Approx. 1.8 m³/h (HKM 200)

- Warm water consumption

- Approx. 0.1 m³/h (HKM 80), Approx. 0.2 m³/h (HKM 200)

- External Dimensions

- 1650 x 780 x 2440 mm (HKM 80), 1700 x 1200 x 3100 mm (HKM 200)

- Weight

- 2100 kg (HKM 80), 4000 kg (HKM 200)

- Automation

- PLC-controlled

- Operation

- Automatic

- Temperature Control

- Automatic product temperature control

- Preheating

- Automatic preheating (stand-by mode available)

- Working mechanism

- Continuous grinding with pressure, friction, shear forces

- Integrated steps

- Automatic preheating and temperature control

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC-controlled

- Cleaning method

- Automatic CIP

- Changeover time

- Minimal due to continuous operation

- Abrasion resistance

- High

- Cleanability

- Yes

- Corrosive resistance

- Stainless steel

- Density/particle size

- 0.5–2.5 g/cm³

- Heat sensitivity

- Yes

- Machine footprint

- 1650 x 780 x 2440 mm (HKM 80), 1700 x 1200 x 3100 mm (HKM 200)

- Weight net

- 2100 kg (HKM 80), 4000 kg (HKM 200)

- Grinding pot filling content

- 80 L (HKM 80), 200 L (HKM 200)

- Continuous grinding

- Yes

- Grinding pot material

- Wear resistant stainless steel

- Agitator shaft

- With wear resistant disks

- Control panel type

- Machine terminal with display

- Integration possibilities

- Compatible with Beater Mill SMM and Differential Mill 310