Oil and fat filling system for industrial use

Optimize your production line with this precise filling solution, designed to handle a range of semi-liquids efficiently, reduce waste, and maintain product integrity in high-speed operations.

Fills and Packages Semi-Liquid Products

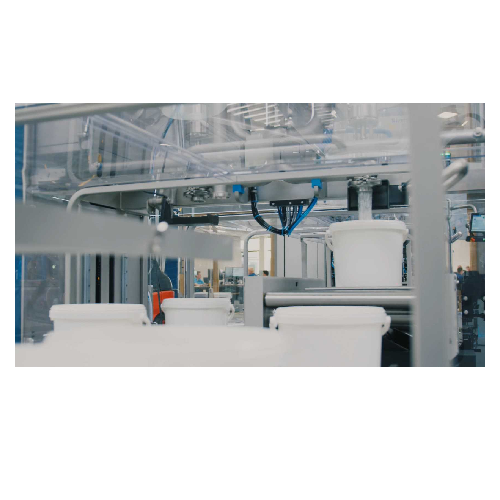

The OLAF from Niverplast B.V. is a high-speed filling machine designed for semi-liquid products, addressing the challenges faced by food and beverage manufacturers, oil producers, and chemical processors. This equipment stands out for its ability to fill up to 12 tons per hour with outstanding precision, utilizing a dual-stage dosing system to ensure accuracy. It processes various semi-liquids, such as oils, fats, and liquid formulations, making it ideal for end-products like vegetable and industrial cooking oils, mayonnaise, and cosmetics.

Engineered with an intuitive touch interface and remote control capabilities, the OLAF integrates seamlessly into existing packaging lines, reducing downtime with its hygienic valve system and stainless steel construction for superior durability and corrosion resistance. Optional features like Clean in Place (CIP) preparation enhance ease of maintenance, while heated anti-drip trays prevent product loss. This machine caters to the needs of those seeking to improve operational efficiency and product quality in high-demand environments.

Benefits

- Enhances production efficiency with high-speed, precise filling up to 12 tons per hour.

- Minimizes product waste and spillage through adjustable box height and anti-drip trays.

- Simplifies maintenance and operations with intuitive touchscreen and remote control.

- Ensures product safety and quality through hygienic stainless steel construction.

- Integrates easily into existing production lines, offering seamless automation and customization options.

- Applications

- Palm oil, Liquid formulations, Fats, Oils, Semi-liquids

- End products

- Cocoa butter, Shortening, Olive oil, Lard, Lotion base, Vegetable oil, Industrial cooking oil, Butter oil, Palm olein, Palm kernel oil, Shampoo base, Liquid soap formulations, Coconut oil, Mayonnaise, Margarine, Salad dressing

- Steps before

- Purification, Mixing, Heating

- Steps after

- Packing, Sealing, Labeling

- Input ingredients

- semi-liquids, oil, fat, boxes, buckets

- Output ingredients

- filled boxes, filled buckets

- Market info

- Niverplast is known for innovative packaging solutions, specializing in industrial engineered-to-order equipment for bag-in-box systems, tray handling, and carton erecting machinery, with a strong reputation for quality and reliability in the packaging industry.

- Capacity

- Up to 12 tons per hour

- Accuracy

- ± 40 g with a standard deviation of ± 15 g

- Material

- Stainless steel

- Automation

- Interactive, intuitive operating software

- Touchscreen

- Easy-to-operate touch IPC

- Hygiene

- Hygienic valve and heated anti drip trays

- Box Height Adjustment

- Adjustable box height to avoid splashing

- Remote Control

- Integrated remote control

- CIP Preparation

- Optional

- Pipe Heating

- Optional

- Automation level

- Intuitive touchscreen, PLC-controlled

- Batch vs. continuous operation

- Batch

- Changeover time

- Easy change of packaging format

- CIP/SIP

- Optional CIP preparation available

- Cleaning method

- Easy access for maintenance and cleaning

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Splash prevention

- Adjustable box height

- Control panel type

- Interactive and intuitive touchscreen

- Adjustable box height

- Avoid splashing

- Easy change of packaging format

- No extension tubes or parts needed

- Interactive and intuitive operating software

- Available in multiple languages

- Optional preparation for CIP

- Clean in Place

- Optional hot water supply

- Pipe heating

- Standard heated anti-drip trays

- Separately adjustable in temperature

- Touch IPC

- Easy-to-operate