Grain cleaning system for high-quality processing

Optimize your grain processing with a versatile cleaning system designed to efficiently separate impurities from grains, ensuring high-quality end products and reducing energy consumption—perfect for operations focused on maximizing throughput and product purity.

Cleans, Grades, and Sorts Diverse Grain Products

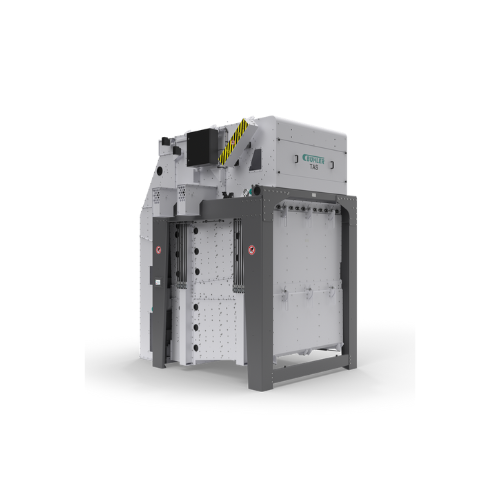

The TAS Universal Cleaning Machine from Bühler Group effectively transforms raw materials into high-quality end products by combining meticulous cleaning, grading, and sorting capabilities. This equipment excels by utilizing a high-density sieve system with gentle circular motions, allowing comprehensive separation of impurities from grains and other food materials. Capable of processing a diverse range of inputs like wheat, rice, pulses, and nuts, it supports production lines in food, grain, and feed industries, delivering results such as whole grain flour, semolina, and almond flour.

The TAS system operates continuously and at high speed, integrating seamlessly into automated production lines. With a large sieve area of up to 48 m² within a compact footprint, it ensures high throughput and reduces operational costs by optimizing airflow with a small fan. Enhanced by Bühler’s digital services, the TAS features remote control capabilities, enabling plant-wide adjustments and recipe settings to optimize yield and quality efficiently.

Designed with options for easy maintenance and safety, it provides quick sieve changes via a front panel and includes an optional sieve changing platform. The machine’s energy efficiency is further enhanced by electric aspiration settings and LED lighting, which also promote long-term sustainability. With improvements in wear protection and maintenance access, the TAS Universal Cleaning Machine is an indispensable asset for any operation aiming for excellence in product purification and quality.

Benefits

- Optimizes operational efficiency by reducing energy consumption through a shared aspiration system.

- Elevates product quality with high-density sieves ensuring thorough impurity separation.

- Maximizes production capacity with a large sieve area, allowing high throughput in a compact footprint.

- Minimizes labor costs and enhances flexibility with remote control capabilities for seamless operation adjustments.

- Enhances sustainability and reduces environmental impact with advanced energy-saving features like LED lighting and efficient airflow management.

- Applications

- Snacks, Dairy, Grains, Pulses, Spices, Aqua feed, Breakfast cereals, Cocoa, Animal feed, Pasta, Pet food, Nuts, Rice, Dried fruits, Wheat, Oilseeds, Confectionery, Coffee, Vegetables

- End products

- Fishmeal pellets, Potato chips, Cocoa nibs, Basmati rice, Chocolate chips, Sunflower seeds, Dehydrated carrots, Whole grain flour, Turmeric powder, Chickpea flour, Kibble, Roasted coffee beans, Raisin mix, Penne pasta, Cornflakes, Semolina, Milk powder, Cattle feed pellets, Almond flour

- Steps before

- Grain handling, Receiving, Storage

- Steps after

- Packing, Palletizing, Weighing, Dosing, Sorting, Drying

- Input ingredients

- grain, wheat, rice, paddy, oilseeds, pulses, spices

- Output ingredients

- cleaned grain, graded grain, high-quality grain product

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Sieve Area

- Up to 48 m²

- Footprint

- Less than 12 m²

- Automation

- Remote control

- Air Usage

- Shared inlet and outlet aspirations

- Energy Consumption

- Reduced due to small fan usage

- Sieves Density

- High density, gentle circular movements

- Sieve Design

- Large, for precise cleaning and grading

- Machine Capacity

- Increased due to automatic inlet regulator

- Sieve Quick Change

- Front panel, no screws

- Working mechanism

- Circular sieve movement

- Integrated steps

- Cleaning and grading

- Automation level

- Remote control/PLC

- Changeover time

- Quick changeover, seamless product changes

- Energy efficiency

- Lower energy consumption with small fan

- Cleaning method

- Manual, with optional remote settings adjustments

- Abrasion resistance

- High

- Biological compatibility

- Yes

- Cleanability

- Easy

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Corrosive resistance (e.g. acids)

- Yes

- Viscosity

- High/Medium/Low

- Multistage cleaning process

- Yes/No

- Grain types

- Wheat/Barley/Rice/Corn

- Machine footprint

- Less than 12 m²

- Sieve area

- Up to 48 m²

- Sieve type

- High density, circular motion

- Expansion chambers

- Two large expansion chambers

- Sieve changing platform

- Optional swing-down platform

- Control panel type

- Remote control capability

- Integration possibilities

- Bühler digital services

- Recipe settings control

- Remote control

- Sieve changing platform

- Optional

- Inlet regulating device

- Automatic

- Lining option

- Polyurethane plates

- Screen changeover unit

- Optional