Making Fruit Powders

Find innovative production technology for making fruit powder and connect directly with world-leading specialists

Food powder is the result of drying and pulverizing food. It has been around since the astronauts when out to space. Fruits have a short shelf life and are difficult to preserve due to their high water content. Fruit powder processing allows you to keep the nutrients of the fruits for a longer time, even off-season.

Stories about fruit powder

Select your fruit powder process

Tell us about your production challenge

Different drying-powdering processes for juice and whole fruits

You can choose other fruit powder processing methods. The most common is spray-dried, where concentrated fruit juice passes through a nozzle into a heated chamber. Spray-dried fruit powder loses vitamins and mineral density but preserves fibers and nutrients.

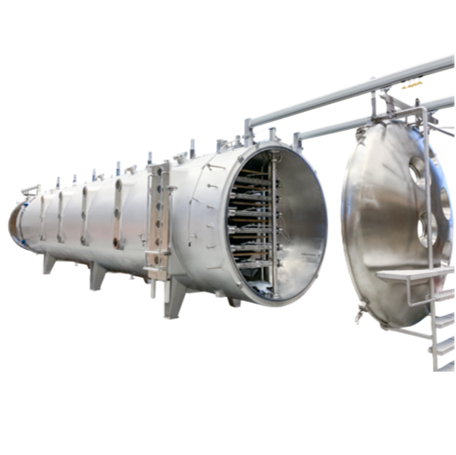

Fruit powder preserves more the nutrients and characteristics from fruits that are not submitted to high temperatures. You can choose a vacuum drier, a low-temperature vacuum environment that evaporates the water. Or choose a freeze-drier where fruits will be frozen in a sealed chamber. Both produce high-quality results.

If you have whole fruits, you clean them and cut them. Then you dehydrate them and finish by grinding or crushing the dried material into powder.

Rise of natural ingredients demand

Fruit powder is a natural ingredient that improves color taste and adds nutritional value. Using fruit powder is critical in the rising demand for natural products. It can be used in beverages, infant food, spices, bakery, cereals, snacks, sauces, and desserts. But also in medicine, dietary supplements, and even cosmetics. Fruit powders are able to be added to many recipes in many industries due to the fact that they can be easily blended into an array products.

The cosmetic industry uses minerals and vitamins from fruit powder processing in skin and hair care products. These ingredients also give color, smell, and texture in the formulations of masques, cleansers, and more.

No more wasted fruits and food

More than a third of the food we produce is wasted, mainly because they are ugly or don’t have a standard size. You can use dehydrated fruits and food to be destroyed to transform them into powder.

Fruit and food powders can be distributed in zones where access to food and refrigeration are difficult. Also, send to places affected by natural disasters. Fruit powders can be used in every home, where they can last all year-round on the shelves using less space.

Processing steps involved in fruit powder making

Which fruit powder technology do you need?

Freeze dryer for high sugar or acid content products

Achieve precise moisture control for challenging high sugar or acid ...

Ultrafiltration for fruit juices and nectars

Optimize your juice and nectars production with precise ultrafiltration, ensu...

Spray drying solution for heat-sensitive products

Optimize the drying of heat-sensitive and challenging materials into hi...

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, ...

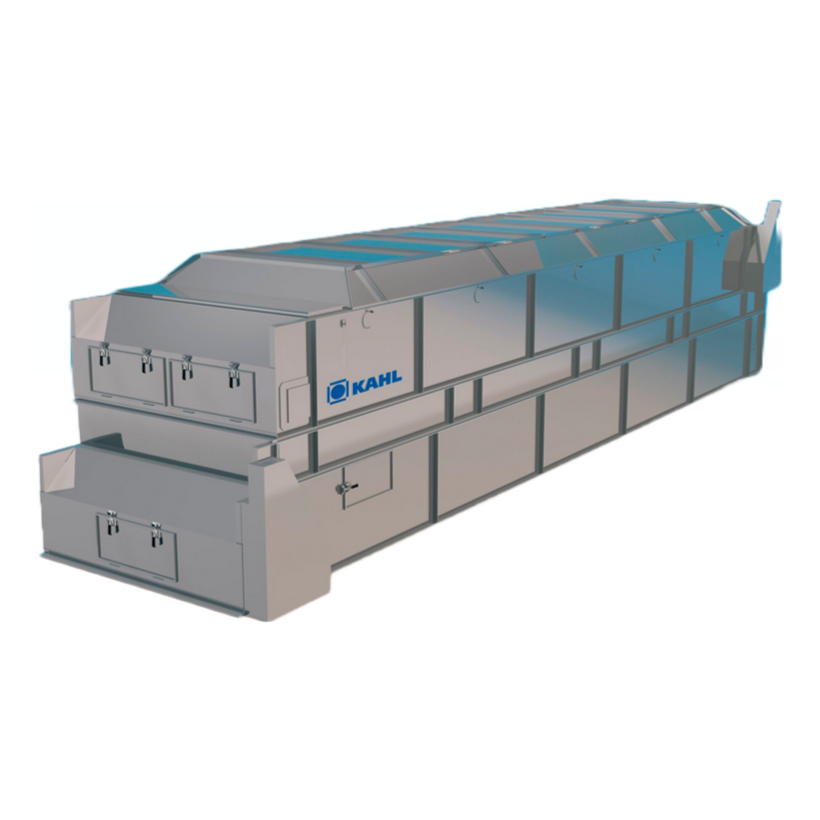

Mesh belt food dryer

Achieve uniform and efficient drying of diverse materials with the mesh belt food dryer, designed to max...

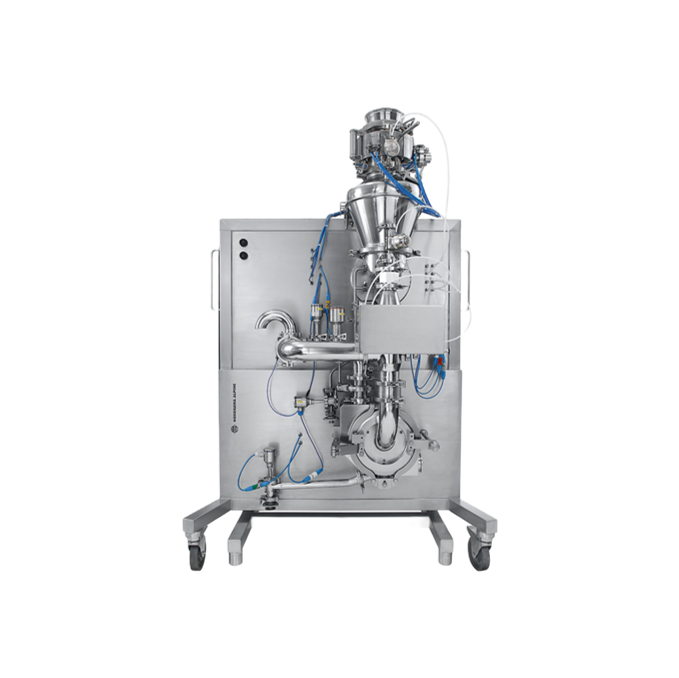

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

Freeze drying system for berries and fruit powders

Delicate fruits with high moisture levels, such as berries, risk losin...

Batch cooker for fruit puree

The fruit pulp is used in many different bakery products, especially as a filling. Since fruit ...

Concentrator for fruit puree preparation

Fruit puree is often an ingredient of various fruit-flavored yogurts, which someti...

Vacuum belt dryer for instant drink powders

Extracting the essential acids and compounds from fruits and plants is a compl...

Vacuum cabinet dryer for plant extracts and functional foods

Plant extracts are vital to functional food preparations. B...

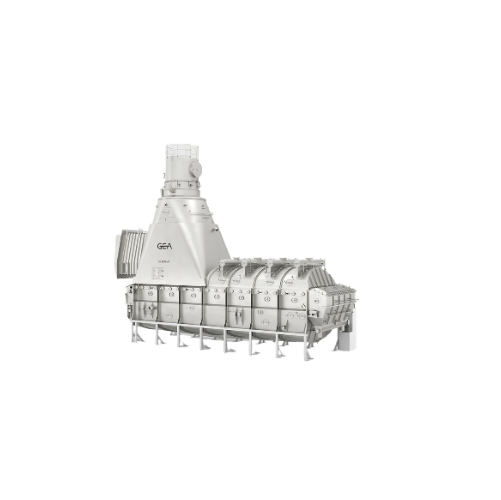

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

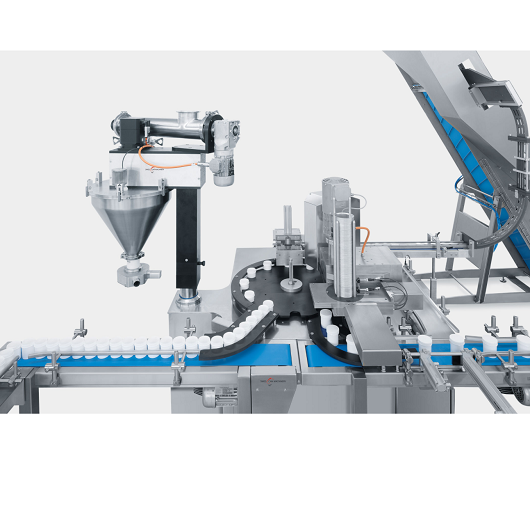

Fast gravimetric powder microdosing 50 - 200 g

Micro-dosing powders of high-value food or chemical products can be challen...

Flexible pasteurizer for packaged food

Autoclaves for sterilising and cooking food products are a mainstay of many producti...

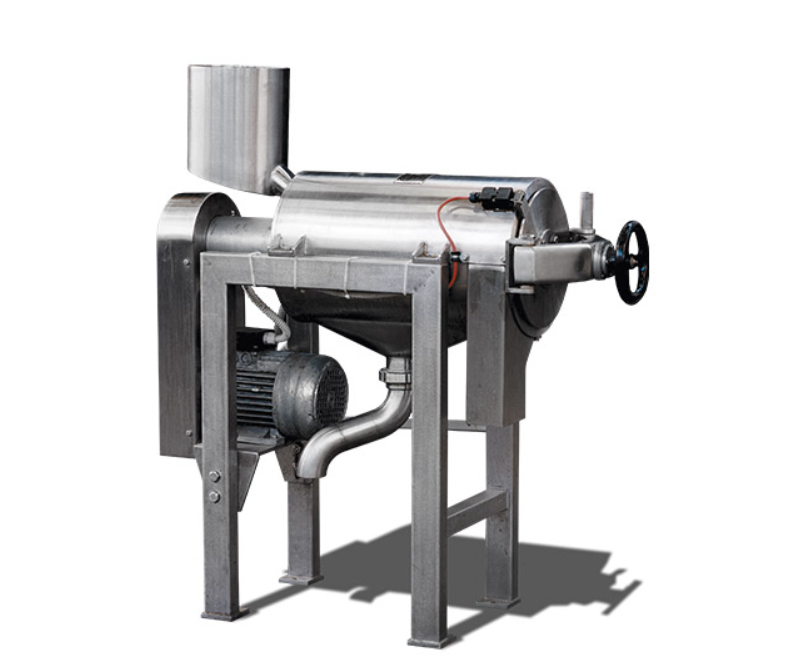

Fruit pulping machine

When making fruit pulp, a pulping machine helps you remove seeds, stems, and skins from your fruit. How...

Can filling equipment

Having separate equipment for different process steps like filling and closing, can put a brake on grow...

Metal detection system for aluminum packages

The magneto reflection system is ideal for detection of metals in aluminium f...

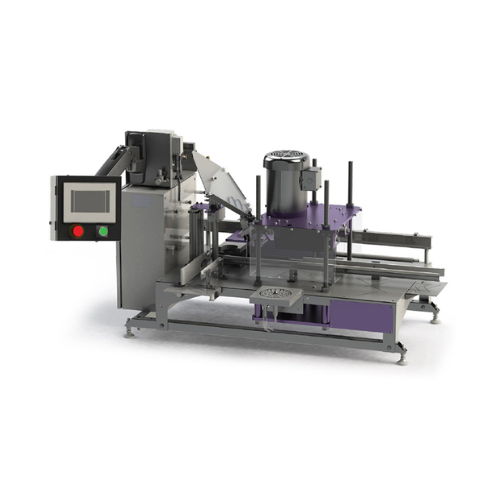

Bagger for open mouth bags

Where a stand-alone bagger is required for filling large, open mouth bags, a delivery method is n...

Horizontal form, fill and seal machine for bags up to 10kg

Bagging small quantities of solids or liquids, whether in pap...