Baby Food Processing Equipment

Find innovative production technology for making baby food and connect directly with world-leading specialists

First commercially sold baby food was created by Henri Nestlé when he combined cow milk with sugar and grains. Baby food industry has since grown to offer everything from whole wheat infant cereals to ramen-flavored baby food. From infant formula to fruit puree, choosing the baby food processing equipment is related to the type of baby food you want to make.

Select your baby food process

Tell us about your production challenge

Baby food processing equipment for infant cereals

Infant cereals provide babies with nutrients, iron and various microorganisms for building their immune system. Baby food can be made from a wide range of raw materials such as rice, wheat, oats and other grains.

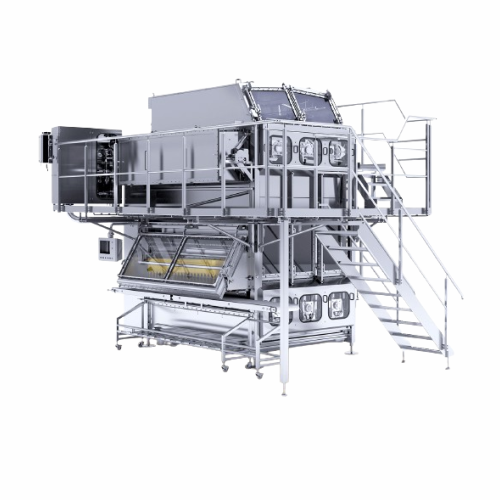

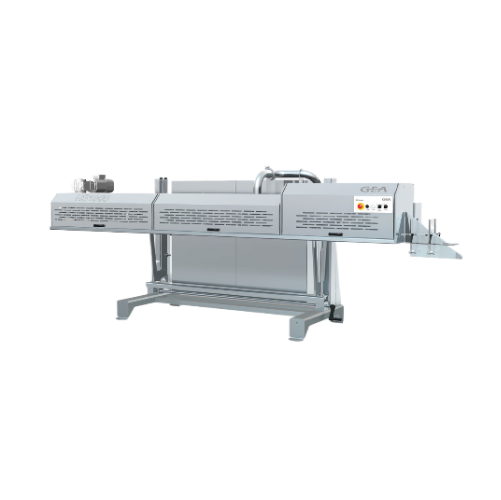

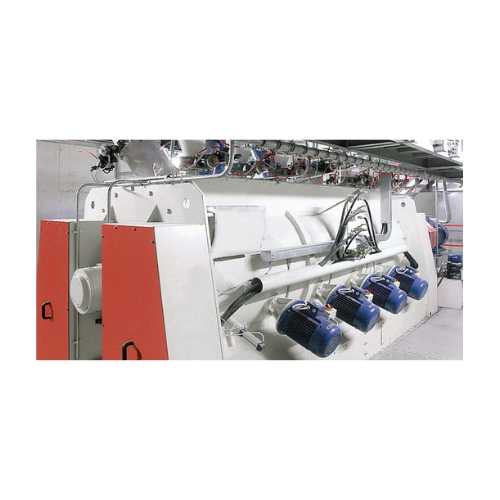

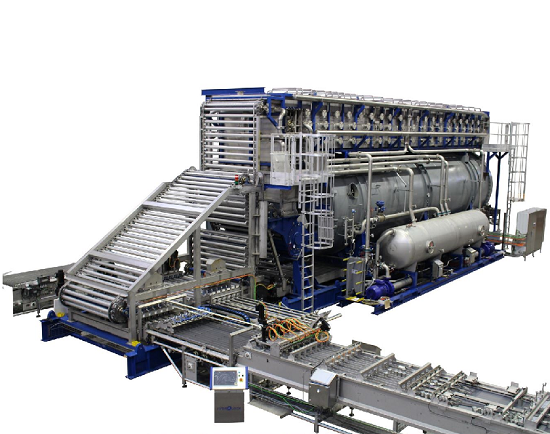

These grains are cooked and milled into small flakes that can be mixed with milk, water or other liquids to the desired consistency. Manufacturers use a whole array of baby food processing equipment and production lines. For example, steam cookers, industrial grinders, sifters and magnetic separators.

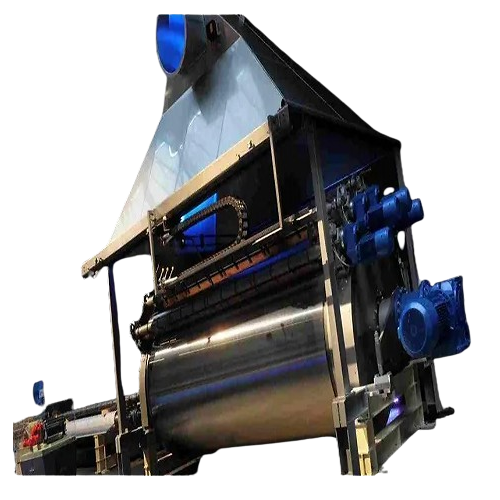

To make high quality infant cereals, harvested grains are rigorously prepped- all possible contaminants are removed and the grains are thoroughly washed. Then, the grains are cooked in steam cookers, until they turn into a slurry. Highly accurate gravimetric dosing systems add valuable minerals and vitamins into the cooked grain slurry. Afterward, the mass is transferred into drum driers to dry and turn the liquid slurry into dry flakes. Rice is one of the most often used grains for infant cereals because it has a low allergen potential and does not contain gluten.

Whole grain vs. refined cereals

There is an ongoing debate on the use of whole grain versus refined cereals for infant food. The key difference between whole grain and refined cereals is the amount of grain’s anatomical components. Whole grains consist of an endosperm, a bran and a germ, while refined cereals consist only of the endosperm. The bran and the germ contain the most fibers, vitamins and minerals of the grain, which means that whole grain cereals have a higher nutritional value than refined cereals. On the other hand, whole grains have more contaminants than refined cereals.

Even though the study suggests that whole grain is more beneficial compared to the refined cereals, baby food manufacturers face the challenge of removing dangerous contaminants such as heavy metals and mycotoxins (toxic chemical products produced by fungi) and arsenic in whole grain rice from whole grain products. Moreover, other issues such as consumer confusion regarding labeling practices and lack of policies on whole wheat intake for infants also have to be resolved by policy makers, researchers and manufacturers.

Fruits, vegetables and meat – how to make baby purees

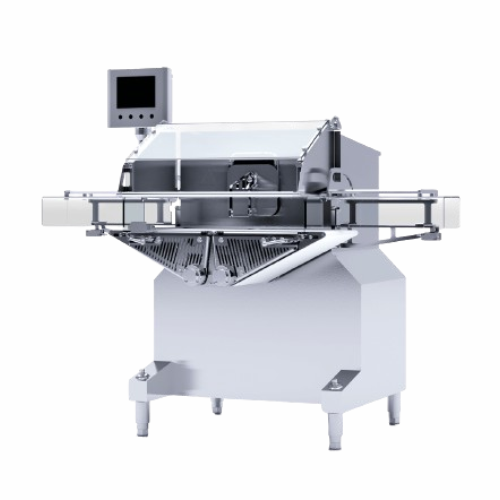

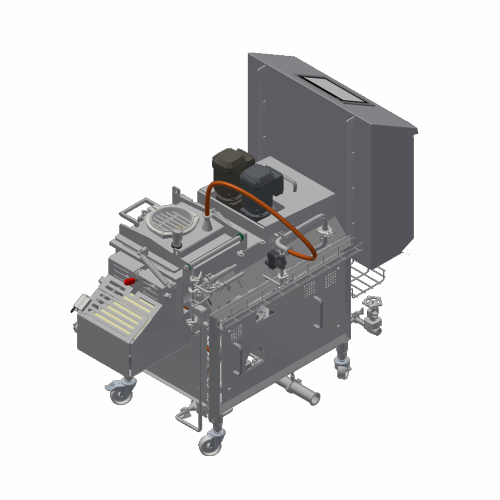

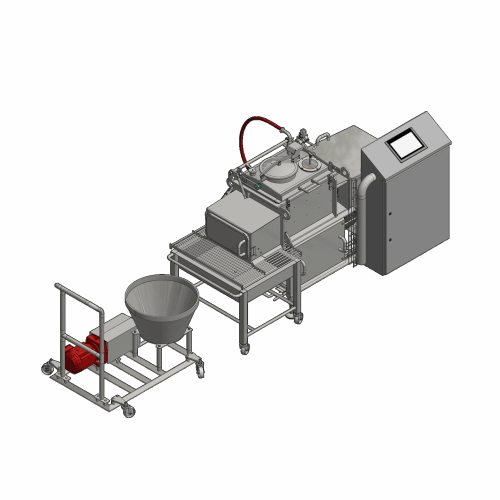

Filled with important vitamins and minerals, baby purees are made from fruits, vegetables and, sometimes, meat. Like infant cereals, baby purees are recommended for babies aged 6 months or older. Each fruit and vegetable has a different method of preparation before being ground and pureed. Depending on which fruit or vegetable you are using for the baby puree, you need various baby food production lines to wash, peel and grind the vegetable to a pulp with industrial graters.

The prepped fruits or vegetables are then cooked in equipment like vacuum cookers. The vacuum cooker preserves all the natural aromas and flavors of the fruits and vegetables – it cuts down on the cooking time of the ingredients because of the lower boiling temperature. The puree is then pasteurized, which removes any potentially harmful microbes and prolongs the product’s shelf-life.

Baby food regulations and standards

There are some important regulations and international standards set for baby food that you should be aware of. The EU has rigid regulations for pesticide residue, explained in the Commission Directive 2006/125/EC on infant cereals. It prohibits the use of some extremely toxic pesticides like fentin, nitrofen and disulfoton. Moreover, manufacturers of baby food have to comply with the EU laws on hygiene, contamination, the use of food additives and the materials used in the manufacturing process. The directive also sets down rules for labeling – the label includes the energy and nutritional value of the products.

In the US, the Food and Drug Administration has stringent rules under the Federal Food, Drug, and Cosmetic Act (the Act) on toxic elements like arsenic, mercury, cadmium and lead in baby cereals and other baby foods. The Act also includes regulations on food allergen controls and sanitation controls. The product’s label must always include nutrition information and serving sizes.

Processing steps involved in baby Food making

Which baby food technology do you need?

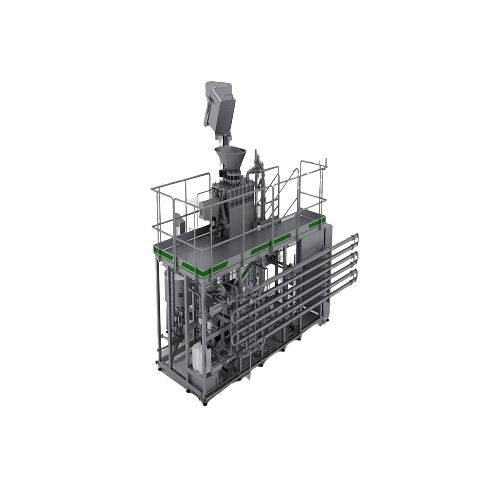

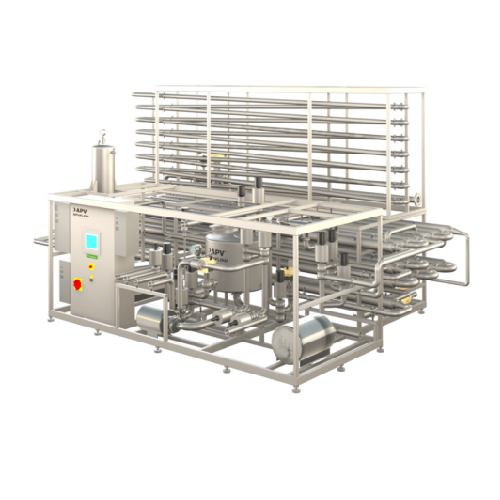

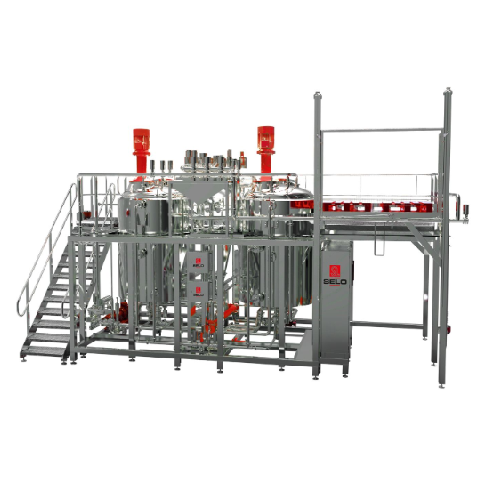

Whey processing line

Streamline whey processing by transforming byproducts into high-value proteins, catering to diverse nutr...

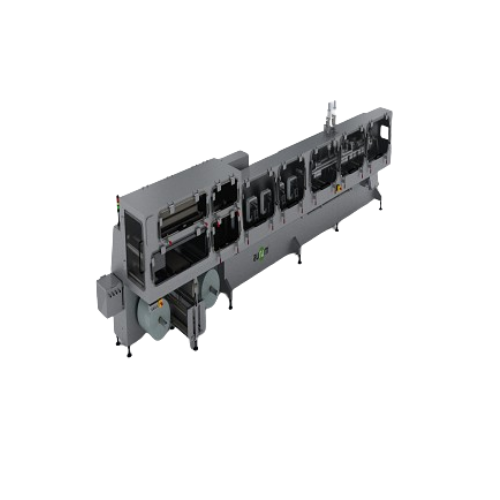

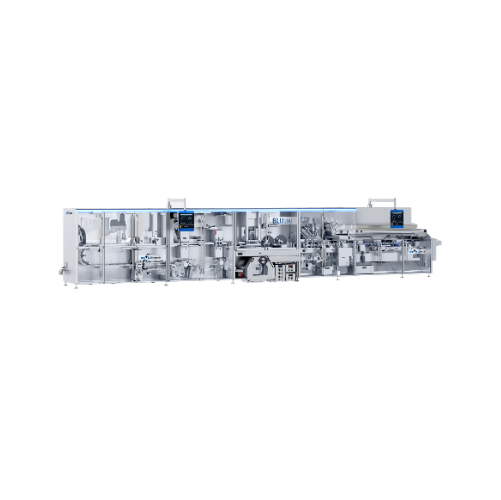

Intermittent end load cartoner for baked goods and snacks

Optimize your packaging line with an efficient, space-saving c...

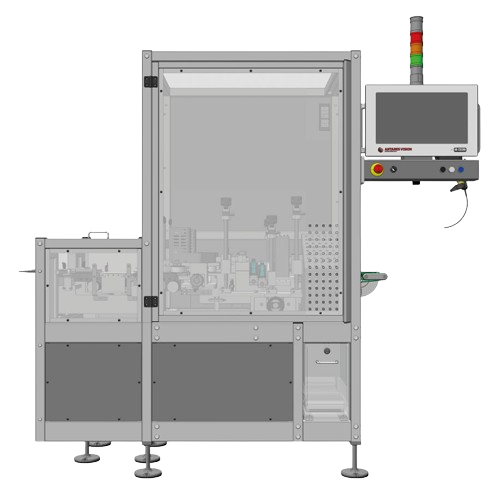

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

Milk powder processing plant

Achieve precise powder formulations with our state-of-the-art milk powder processing plant, ide...

Vertical colloid mill for emulsifying and homogenizing

Optimize your production line with precise particle size reduction...

Centrifugal pumps for food & beverage and biopharmaceutical applications

Optimize your liquid transfer processes with p...

Aseptic sampling devices for biopharmaceutical applications

Secure aseptic sampling ensures your high-value biopharmaceu...

Mobile cleaning-in-place unit for process equipment

Ensure seamless cleaning of diverse process equipment with a mobile, ...

Compact cleaning in place units for food industry

Optimize your production line with a compact system designed for effici...

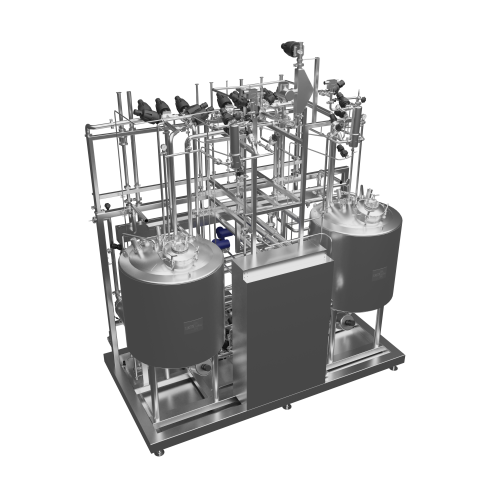

Cleaning-in-place for multiple equipment in food industry

Ensure precise hygiene and traceability with a system designed...

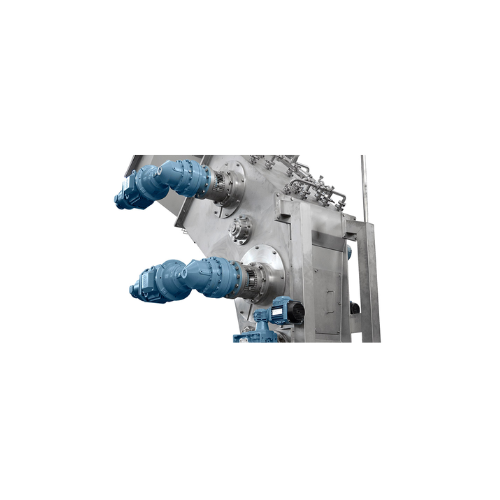

Industrial agitation and mixing solutions

Enhance your production line efficiency with engineered agitation and mixing sys...

Cleaning and sterilization in place for hygienic control

Ensure maximum hygiene and sterility in your production line wit...

Stainless steel process vessels for biopharmaceutical applications

Ensure seamless mixing and sterilization with engine...

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

Direct steam injection system for heat treatment

Achieve precise thermal processing and enhance product quality for comple...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Wet mixer for viscous and paste-like products

Achieve high-quality mixing of medium to highly viscous products with precis...

Heating and cooling system for food and dairy products

Achieve precise temperature control and efficient processing with ...

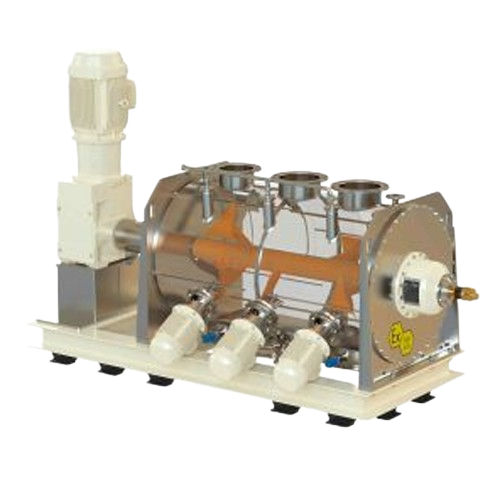

Industrial powder blender

Optimize your production with precise dry blending, ensuring efficient mixing processes and seamle...

High shear mixer for viscous powder dissolution

Need consistent, homogeneous blending of high-viscosity liquids and powder...

Inline high shear mixer for low to medium viscosity liquids

Efficiently dissolve large quantities of powders into liquid...

Inline mixer for uniform powder blends

Achieve uniform powder blends in minutes with this high shear inline mixer, designed...

Inline high shear mixing for dairy and condiments

Streamline your production line with innovative inline high shear mixin...

High-shear inline mixer for lump-free products

Achieve consistent texture and prevent clumping in liquid and powder blends...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

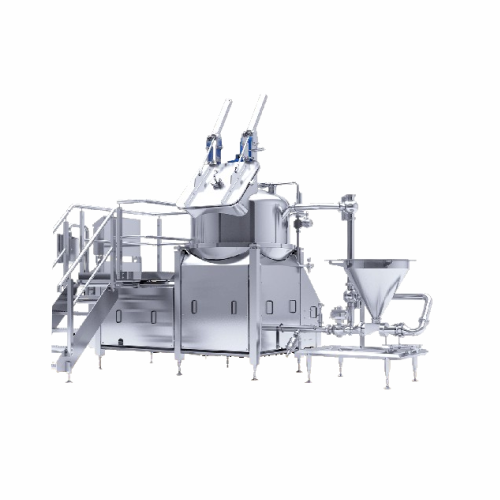

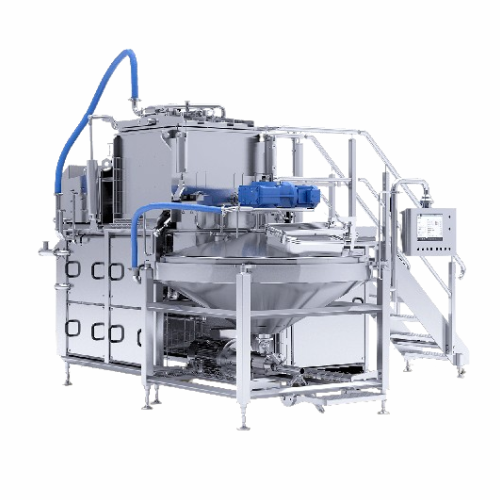

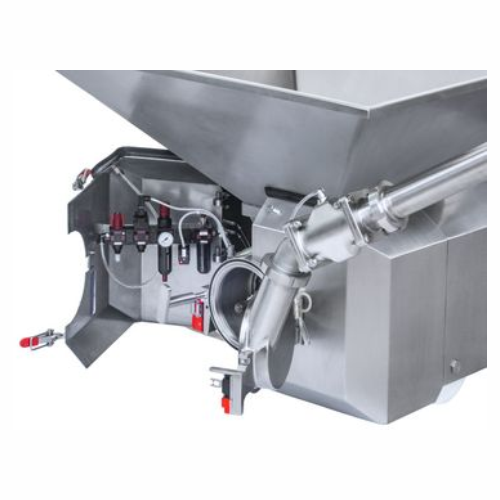

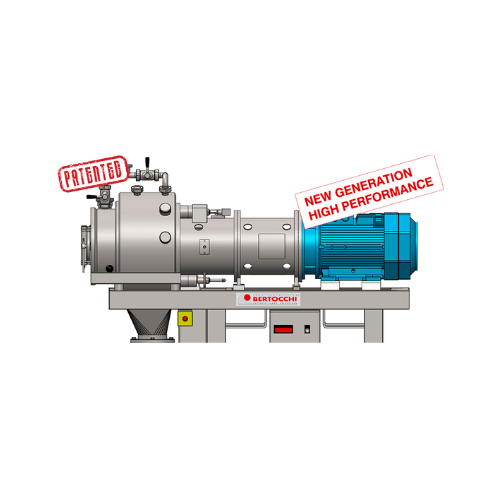

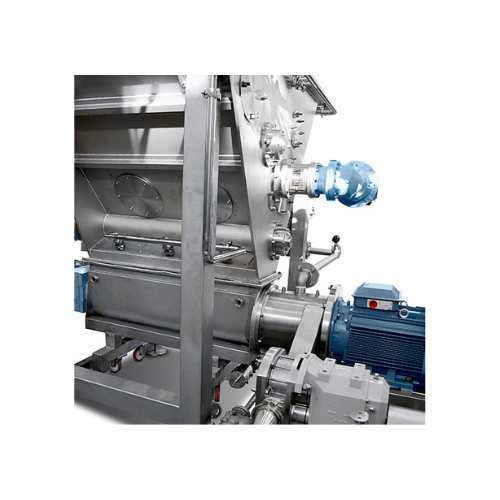

Industrial mixer for baby food and dairy production

Optimize your production line efficiency with a versatile mixing solu...

Customized oil storage tank for industrial use

Enhance production efficiency and ensure seamless integration with customiz...

Cooling system for vegetables and meat

Optimize cooling efficiency with dual counterrotating agitators and expansive surfac...

Heating solution for vegetable and meat products

Achieve efficient heating and optimal heat transfer for sauces and dairy ...

Conical buffer tank for hygienic dairy and food processing

Achieve efficient processing of high-viscosity products with ...

Food mixing and blending system

Enhance your production line with a versatile system designed for gentle processing needs, o...

Jar sealing system for plastic and glass containers

Achieve precise and efficient sealing of plastic and glass jars with ...

Dense phase pressure conveying system for fragile powders

Ensure gentle handling and long-distance transport of fragile ...

Depalletizer with accurate level compensation

Optimize your high-speed assembly line with a depalletizer designed for prec...

Double cone blender for fragile and abrasive material

Achieve homogeneous blends of fragile materials while minimizing da...

Double cone blender for homogeneous solid-solid mixtures

Need uniform blending for complex solid mixtures with diverse de...

Industrial v-type solids blender for homogeneous mixture

Achieve precise blending of diverse powders and solids using the...

Industrial cooking kettle for food processing

Achieve seamless integration of cutting, mixing, and cooking processes to cr...

Filling and sealing system for pre-formed cups

Experience seamless integration of hygienic filling and sealing with adapta...

Flexible filling and sealing system for pre-formed cups

Achieve precise portioning and consistent quality in your product...

High-speed pouch filling and sealing system for food and dairy

Achieve precise spouted pouch filling with minimal waste ...

Rotary doypack packaging system for various materials

Enhance your packaging line with versatile doypack machines designe...

Rotary doypack for granules, liquids, and powders

Enhance your packaging line with a rotary doypack system designed to ef...

Packaging solution for small bottles and jars

Effortlessly seal and fill non-stackable containers, ensuring precision for ...

Tray sealing machine for buckets

Ensure efficient sealing and preservation with high-speed tray sealing for various food pro...

Vertical stick pack sachet packaging solution

Ideal for mid-scale operations, this vertical stick pack machine streamlines...

Automatic vertical casepacker for efficient packaging integration

Streamline your packaging process with a vertical cas...

Tray sealer for food packaging buckets

Enhance your packaging efficiency with a highly adaptable tray sealer, designed for ...

Tray sealer for packaged food products

Optimize your food packaging with precise sealing and advanced Modified Atmosphere P...

Traysealer for modified atmosphere packaging - food products

Optimize your packaging line with this semi-automatic trays...

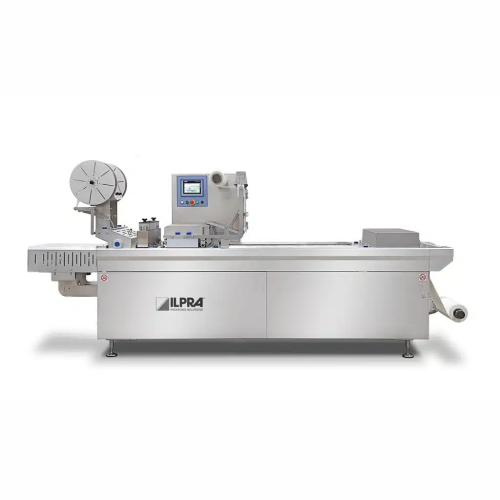

Traysealer for medium production

Streamline your packaging process with high-speed traysealing, ensuring freshness and exten...

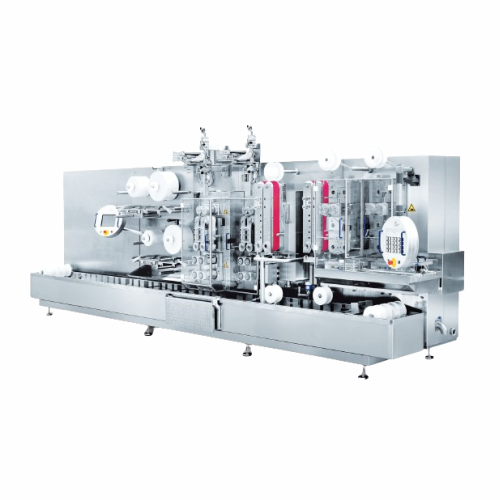

Thermoforming packaging solution for food and medical applications

Enhance your packaging line with a solution designed...

Compact thermoforming packaging system for food industry

Revolutionize your packaging line with a space-saving solution t...

Linear and auger weighing systems for non-free-flowing products

Optimize your production line with precise weighing and ...

Metal detector for small to medium-sized products

Ensure product integrity and compliance by seamlessly integrating metal...

Multi head weigher for precise portioning

Ensure consistent product portions with our multi head weigher, ideal for high-s...

Vertical form fill seal for small to medium production runs

Ideal for scaling production, this compact packaging solutio...

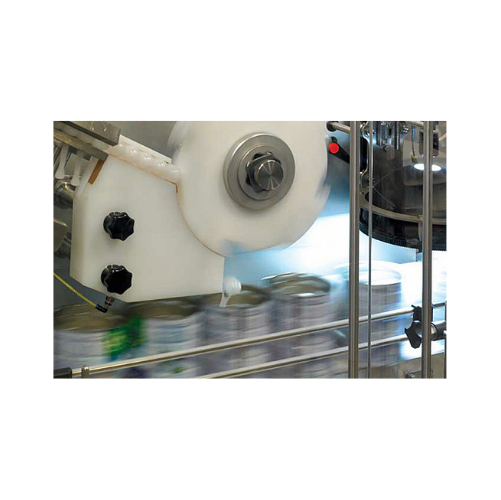

Automatic c-wrap labelling for packaged products

Enhance your production line with precise C-wrap labelling, seamlessly in...

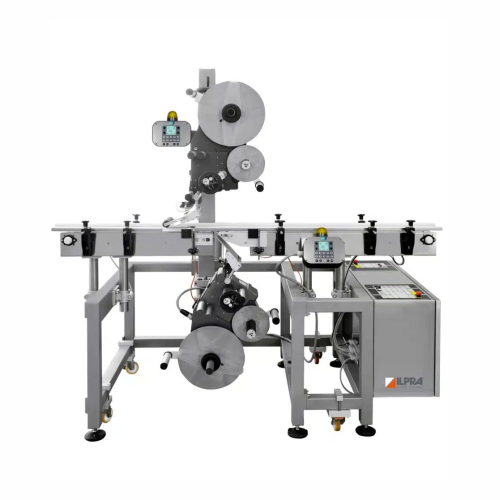

Automatic top & bottom labelling system

Enhance your packaging line efficiency by applying precise top and bottom labels to...

Industrial check-weigher for accurate product weight verification

Ensure precise weight compliance and reduce waste wit...

Rotary filler and sealer for dairy products

Optimize your filling and sealing needs with a compact solution designed for c...

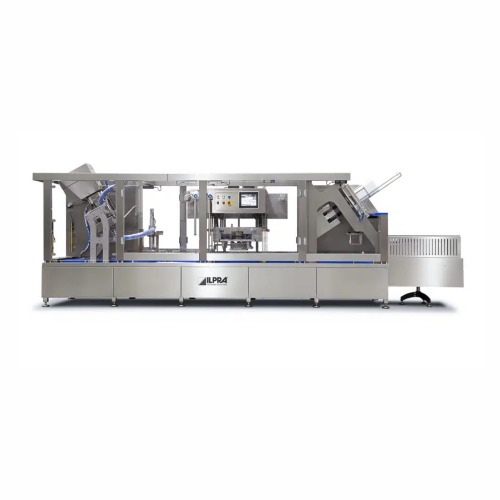

Automatic filling and sealing solution for medium to large production

Streamline your high-capacity filling and sealing...

Rotary filler for optimized production processes

Streamline your fill and seal process with precise timing control and enh...

Entry-level in-line traysealer for ready-to-eat meals

Streamline your ready meal packaging with a compact traysealer that...

Semi-automatic tray sealer for skin packaging

Optimize your small-scale food packaging with a compact tray sealer designed...

Traysealer for small scale food packaging

Improve your production efficiency with a compact traysealer designed for versat...

Industrial pick and place system for packaging

Streamline your packaging line with precise robotic pick and place operatio...

High-speed continuous rotating packaging solution

Transform your packaging efficiency with versatile operations, accommod...

Homogenizers for high-pressure applications

Achieve unparalleled product consistency and stability with precision-engineer...

High-speed cheese slice wrapper

Achieve unparalleled efficiency with the high-speed wrapping machine that securely packages ...

Multifunctional batch cooker for various food products

Optimize your production line with a versatile batch cooker design...

Lump-free emulsifier and steam batch cooker for processed cheese

Achieve consistent, lump-free processed cheese and crea...

Continuous cooker for high-volume food processing

Elevate your production efficiency with a continuous cooker that ensure...

Mozzarella cooker stretcher for continuous production

Experience continuous mozzarella production with steam injection te...

Pilot unit for processed cheese slices

Perfect for R&D and small-scale production, this adaptable unit offers high fle...

Processed cheese slice production system

Reduce recontamination risks in cheese production with a system designed for high-...

Cheese forming and slicing system

Optimize your cheese production with high-speed, precision forming and slicing, ensuring ...

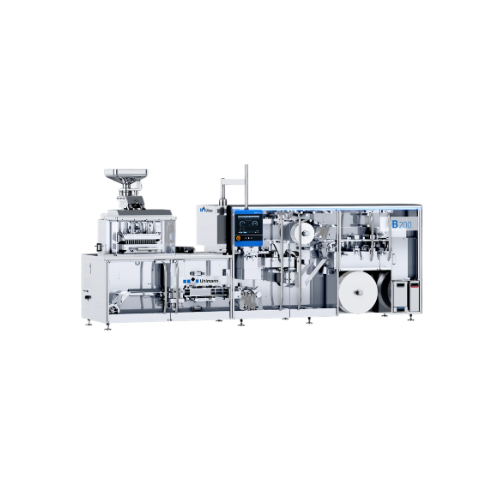

Individually wrapped processed cheese slice production line

Efficiently produce consistent, individually-wrapped cheese ...

Separating packed cheese products from packaging

Efficiently separate individual cheese portions from packaging, reducing ...

Cheese and butter block grinder

Efficiently transform frozen cheese and butter blocks into manageable sizes for continuous p...

Cheese packaging system for mixed cheese types

Optimize your cheese production line by seamlessly integrating a system des...

Processed cheese stick cutter

Achieve precise and consistent cheese stick production with a machine designed to streamline f...

Cheese ribbon cutting solution

Achieve precise and efficient cheese ribbon cutting with high-speed operations, ensuring perf...

Automatic cheese stack and grouping system

Efficiently stack and group cheese slices to streamline your production line an...

Processed cheese slice forming system

Effortlessly produce high-quality Slice-on-Slice cheese slices, cubes, shreds, and st...

Multifunctional batch processing system for processed cheese

Enhance your production line with a sophisticated batch pro...

Batch processing system for processed cheese and sauces

Optimize your food processing line with a versatile batch process...

Batch processing system for processed cheese and various food products

Optimize your food production line with a multif...

High pressure processing for bulk liquid beverages

Streamline your liquid processing with high-pressure in-bulk technolog...

Hygienic conveyor belts for food manufacturing

Ensure bacteriological safety and boost productivity with hygienic conveyor...

Twin ribbon blender for processed cheese and meat products

Achieve seamless blending and consistent feeding for large-sc...

Cheese grinder for fine cheese grinding

Achieve optimal protein emulsification and minimize waste with this high-capacity g...

Magnet for emulsion technology for lump-free blends

Achieve perfectly smooth and stable emulsions in a single pass with a...

Automated filter cleaning system for food production lines

Eliminate frequent production interruptions by utilizing an a...

Cheese cube and shreds production line

Achieve precision cutting for cheese products while seamlessly integrating forming a...

Empty container inspection for pharma packaging

Ensure ultra-clean packaging by detecting glass faults and contaminants be...

Final product inspection system for pharmaceutical containers

Ensure the integrity and precision of packaged pharmaceuti...

Versatile labeller for food industry

Enhance your packaging line with a versatile labelling machine capable of applying wra...

Industrial grinder for ultra-fine grinding and homogenizing

Enhance your production line with versatile grinding technol...

Stacking and bagging system for baby diapers

Optimize your production line with this high-speed solution designed for seam...

Ketchup and sauce processing line

Achieve precise mixing, cooking, and concentration for your sauces and purees, ensuring o...

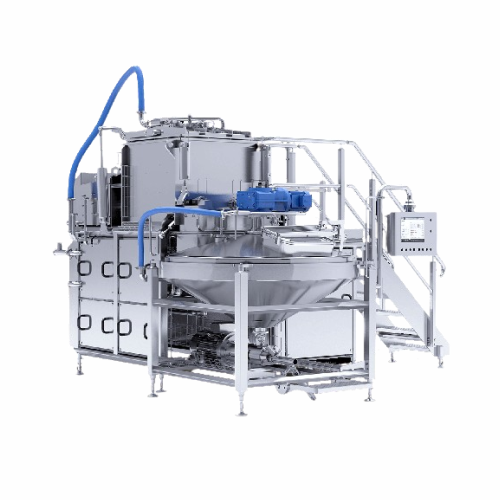

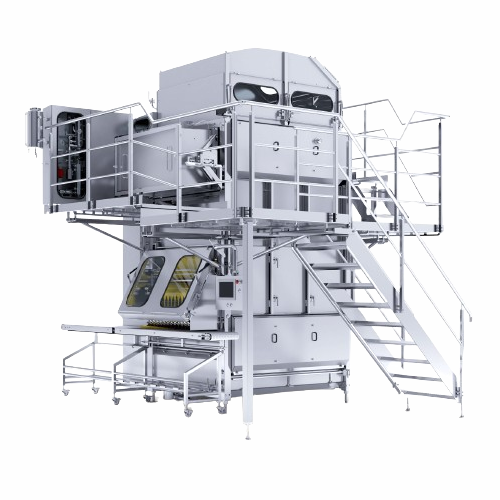

Marmalade, sauces, nectars, and baby food processing solution

Maximize flexibility in your production line with a system...

Production solutions for convenience foods

Effortlessly transform your innovative recipe ideas into consistent, high-quali...

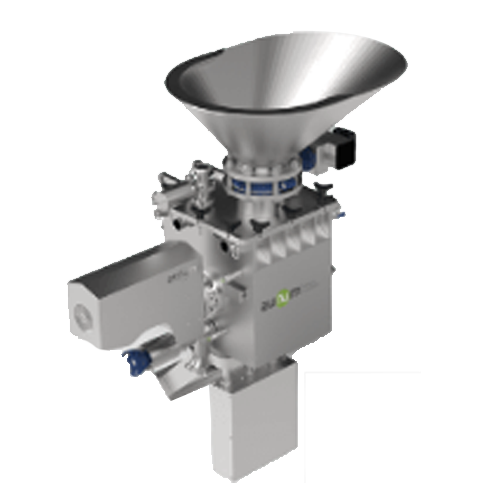

Micro dosing system for precise powder weighing

Achieve unparalleled dosing accuracy in your production line with a system...

Calibratable big bag filling station for dust-free operations

Ensure precise, dust-free filling of bulk bags with ergono...

Pneumatic dosers for variable density products

Achieve precise dosing for liquid to dense products with versatile pneumati...

Electric cooker for preserved food preparation

Efficiently streamline your preserved food production with a multifunction ...

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

General purpose freeze dryer for small commercial batches

Maximize your production line’s flexibility with this ve...

Tunnel for thermal treatment of packaged foods and beverages

Optimize your thermal processing with this customizable tun...

Industrial cooking kettles for food processing

Optimize your production with versatile cooking kettles designed to handle ...

High-precision rotary weight filler for edible oils and sauces

Achieve exceptional filling precision with solutions desi...

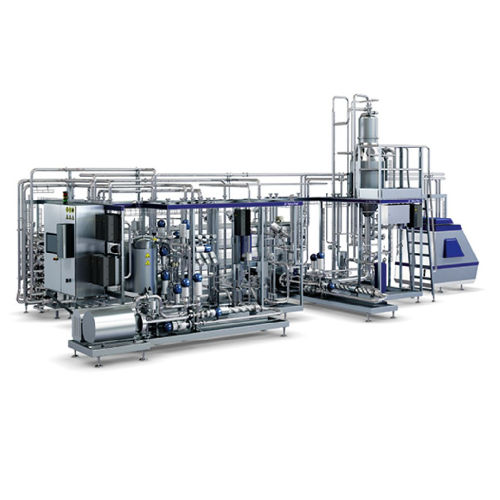

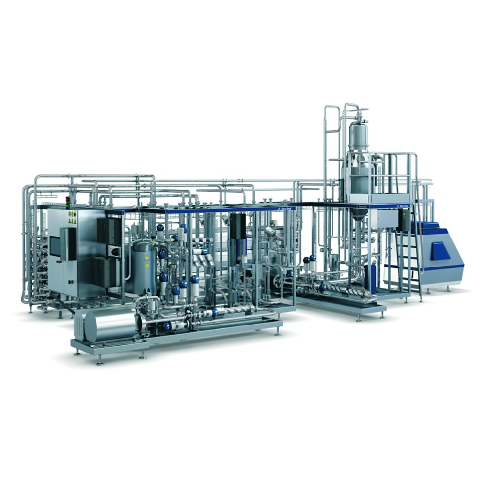

Clean-in-place systems for biotechnology and pharma

Ensure seamless transitions between production batches with efficient...

Top load and side load case packer with vision guided robotics

Optimize packing efficiency and flexibility with a versat...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Industrial depitter for stone fruits

Effortlessly process stone fruits into smooth purees and nectars with a continuous, co...

Industrial liquefying and crunching solution for frozen fruits and vegetables

Efficiently transform frozen produce int...

Turbo extractor for tomato and fruit puree processing

Optimize your production line with high-capacity turbo extraction f...

Frozen extraction turbo extractor for fruit and vegetable purees

Efficiently transform frozen fruits and vegetables into...

Cold extraction system for fruits and vegetables puree

Optimize your fruit and vegetable puree production with a versatil...

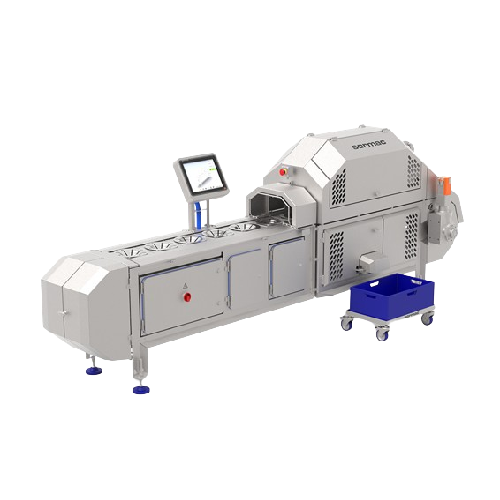

Washing and sorting line for fruits and vegetables

Efficiently achieve pristine fruit and vegetable cleanliness while enh...

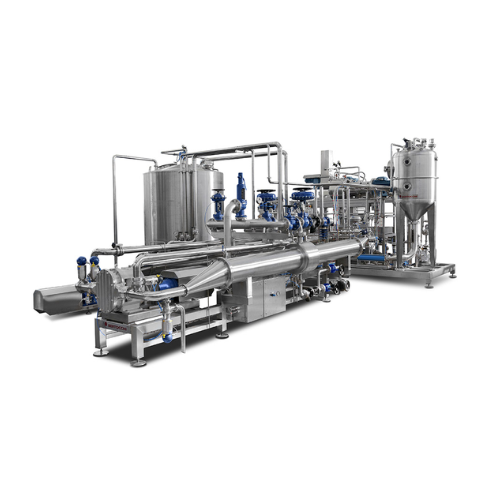

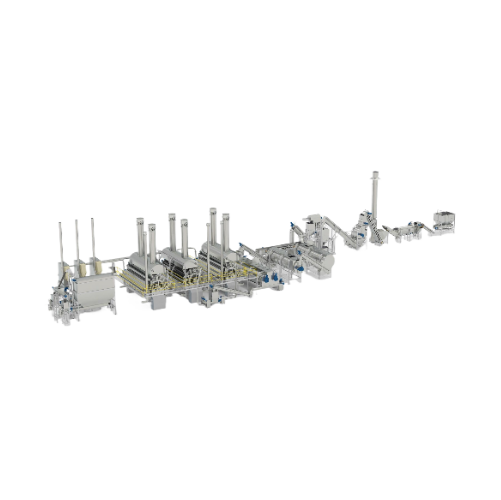

Line for production of fruit and vegetable purees by cold extraction

Streamline your puree production with innovative c...

Frozen extraction line for fruit and vegetable purees

Overcome challenges of processing frozen fruits and vegetables effi...

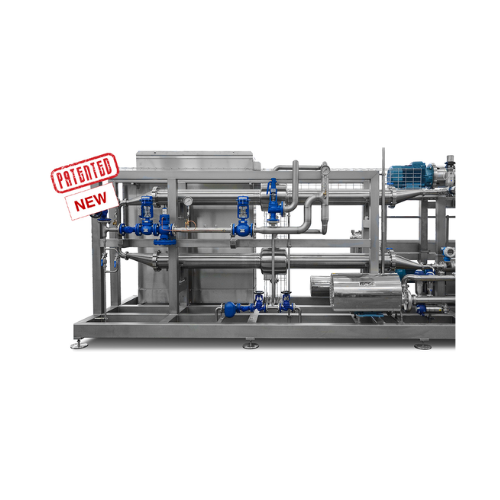

Cold extraction deaeration system for fruit and vegetable purees

Achieve superior puree quality with our system that ens...

Cold extraction system for fruit and vegetable purees

Optimize fruit and vegetable puree processing with cold extraction,...

Cold extraction line for fruit and vegetable purees

Enhance puree quality with minimal thermal stress through a seamless ...

Cold extraction and enzymatic deactivation for fruit and vegetable purees

Enhance your puree quality with advanced col...

Turbo extractors for tomato and fruit hot extraction

Optimize your fruit and vegetable processing with high-capacity turb...

Multi feeding system for baby food and purees

Streamline your puree production with a versatile feeding system that expert...

Cold extraction and deaeration system for fruit and vegetable purees

Ensure high-quality fruit and vegetable purees wit...

Crunching and dosing solution for frozen fruits and vegetables

Streamline your processing line with a versatile system d...

Cold extraction turbo extractor for fruit and vegetable puree

Optimize your processing line with continuous cold extract...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

Industrial mixer for liquid and viscous products

Achieve precise mixing and homogenization of high-viscosity liquids and s...

Vacuum deaerator for elimination of gases

Optimize your product quality by eliminating occlusive gases with this advanced ...

Vertical ribbon mixer for solids and powders

Achieve rapid, uniform mixing of powders and solids while preserving particle...

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Industrial vacuum mixer and reactor for liquids

For manufacturers needing precise blending and stability, this advanced va...

Vacuum mixer for liquids and semi-solids

Achieve precise mixing and homogenization of liquid and semi-solid formulations wi...

Colloidal mill for fine grinding and homogenisation

Optimize your liquid and semi-solid processing by achieving precise p...

Conical screw mixer for solids and powders

Achieve precise homogenization of your solid and powder mixtures with minimal e...

Double cone mixer for powders and solids

Ensure gentle mixing of fragile powders and solids with a low-speed, non-forced bl...

Sterilization for food and pharmaceutical processing lines

Ensure your liquid product’s sterility before productio...

High-efficiency high-capacity reactor for industrial processing

Enhance production efficiency with a reactor system desi...

Aseptic cooking line for plant-based products

Enhance your production efficiency and product quality with an advanced doub...

Aseptic cooking line for industrial food processing

Achieve seamless aseptic cooking and filling for diverse food product...

Aseptic linear doypack filler

Ensure extended shelf life and preserve quality in liquid food products with this high-speed a...

Rotary filler for preformed containers

Ensure microbiological safety and extended shelf life for your liquid products with ...

In-line checkweighing and printing system for cartons

Ensure precision and efficiency in your packaging line with a compa...

Checkweighers for medium and small products

Ensure precise weight control in high-speed production lines with advanced che...

Combi x-ray and checkweigher for vertical products

Ensure accurate weight control and safety by detecting foreign bodies ...

Combi x-ray and checkweigher for vertical products

Ensure precise weight control and contamination detection for vertical...

Contact drum dryer for industrial food and chemical processing

Optimize your drying process with a contact drum dryer th...

Precision powder mixer for baby formula

Achieve consistent texture and rapid homogenization for sensitive powder blends lik...

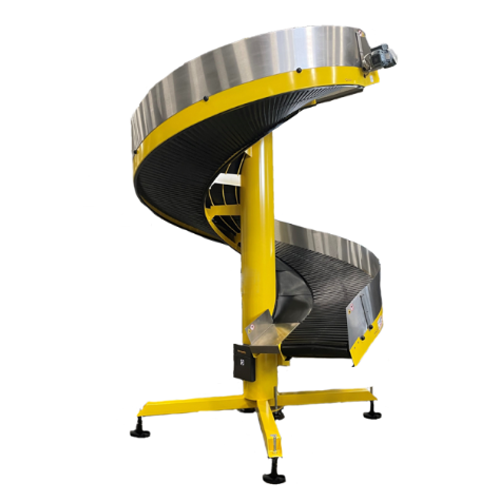

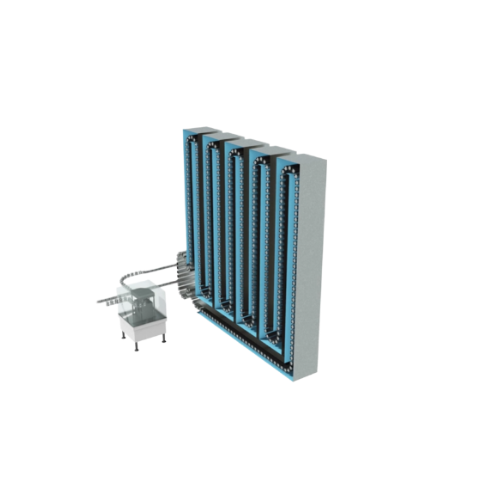

Spiral conveyor for logistics and packaging

Ensure seamless elevation and transportation of diverse products with this ver...

Modular conveyor system for internal unit load transport

Optimize your production line with a versatile conveyor system t...

Curved conveyor for logistics and packaging

Efficiently tackle space constraints in your production line with a flexible c...

Controlled spiral conveyor for logistic centers

Efficiently manage parcel flow and minimize product damage with this spira...

Spiral conveyor for repeating size cases

Optimize your line’s efficiency by elevating rigid items at higher inclines,...

Scraped surface heat exchanger for viscous products

Efficiently handle challenging viscosities and heat-sensitive product...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

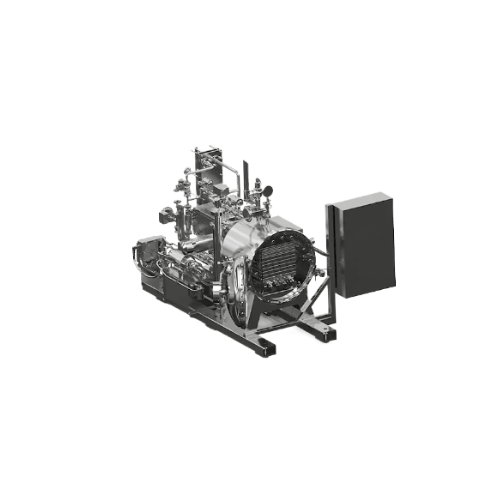

Sterilization pilot systems for small batch heat treatment

Optimize product safety and quality in small batch production...

Tamper evident heat tunnel for safety banding

Achieve precise and consistent tamper-evident sealing on containers with a h...

Industrial crate washing system

Optimize your production line with a solution that ensures pristine cleanliness of crates an...

Multifunctional washer for fruits and vegetables

Achieve impeccable cleanliness in your food processing line with a versat...

Product in tote/crate washer for fresh produce

Enhance the cleanliness of your production line by ensuring that crates and...

Industrial swirl bath washer for sliced vegetables

Achieve optimal cleanliness with a delicate touch—this advanced swirl ...

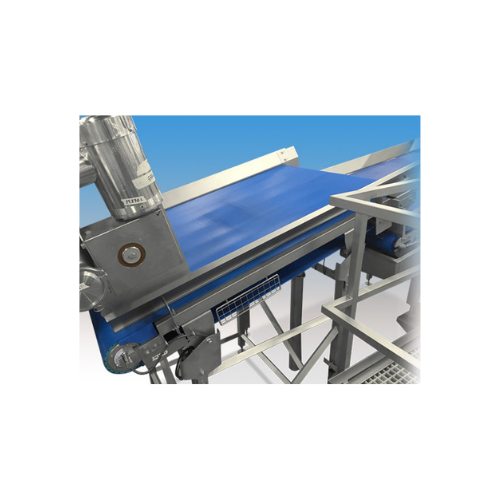

Flat belt product transfer conveyor for food processing

Efficiently streamline your production line with a hygienically d...

Twin lane separator for automated tray sealing

Optimize your production line with this conveyor system designed to effortl...

Semi-automatic tray sealing solution

Streamline your production line with a versatile tray sealing solution that enhances p...

Semi-automatic tray sealing for ready meals

Achieve versatile packaging with a semi-automatic tray sealing solution design...

Semi-automatic tray sealer for ready meals

Achieve optimal freshness with consistent sealing, maximizing shelf life for va...

Air and suction dryers for fresh salads and vegetables

Ensure longer shelf life and optimal quality for your fresh produc...

Centrifuge for drying fresh-cut vegetables

Enhance your production line with reliable surface water removal from fresh pro...

Centrifuge for drying fragile salads

Achieve consistent drying of delicate leafy greens with minimal damage, enhancing prod...

Automatic tray sealer for high-speed food packaging

Optimize your production line with a high-capacity tray sealing solut...

High-speed tray sealer for food packaging

Streamline your packaging process with high-speed tray sealing, reducing labor c...

Automatic tray sealing system for high-speed packaging

Experience seamless high-speed packaging with this versatile tray ...

Automatic tray sealer for high-speed production

Ensure your product packaging stays fresh and secure with this high-capaci...

Industrial case packing solution for high-speed operations

Optimize your production line with a compact, efficient case ...

Bench mounted tray sealer for small-scale production

Perfect for pilot runs and small batches, this compact tray sealer e...

Hand operated tray sealer for small-scale food production

Optimize your packaging process with this compact tray sealing...

Bench mounted tray sealer with gas flush

Optimize your production line with a compact tray-sealing machine designed for pre...

Linear conveyor tray sealing

Experience unparalleled flexibility and efficiency in tray sealing with high-speed integration,...

High throughput tray conveyor system

Looking to streamline your tray sealing process? This modular conveyor system integrat...

High-speed tray sealer for food

Enhance your packaging line’s efficiency with a high-speed, in-line tray sealer design...

Industrial high speed tray sealer

Enhance your production line efficiency with precision sealing capabilities, accommodatin...

Automatic tray sealer

Maximize throughput and shelf life with our high-speed inline tray sealing solution, ideal for diverse ...

In-line tray sealer for high-speed packaging

Optimize your packaging line with a high-speed solution that accommodates mul...

High-capacity tray sealer for vacuum gas packaging

Enhance your production efficiency with a versatile twin-lane tray sea...

In-line tray sealing system

Streamline your packaging line by implementing a high-speed, in-line tray sealing system designe...

High-capacity tray sealer for poultry, meat & seafood

Optimize your high-speed packaging line with this large-capacity tr...

Automatic tray sealer for high-speed packaging

Streamline your packaging line with an in-line tray sealer that adapts to t...

Large-capacity automatic tray sealer

Optimize your production line with this tray sealer, designed for high-speed sealing a...

Automatic inline tray sealer for food packaging

Streamline your packaging process with high-speed, reliable tray sealing t...

R&d vessels for research and development centers

Optimize your R&D operations with versatile vessels designed to hand...

Customizable storage tanks for industrial use

Optimize your production with versatile storage tanks designed for precise c...

Automatic tray sealing system

Optimize your packaging line with versatile tray sealing technology that accommodates various ...

Energy efficient steaming for fresh produce

Achieve exceptional product quality while minimizing energy use by up to 90% w...

Industrial water belt cooler for fresh produce

Ensure consistent cooling for various food products with a system designed ...

Clean-in-place tanks for industrial sanitation

Optimize your sanitation processes with clean-in-place tanks, designed to r...

Industrial melt tanks for butter and chocolate

Reduce manual labor and elevate safety in your production line with a melt ...

Industrial pressure vessels

Ensure product integrity and regulatory compliance with engineered-to-order pressure vessels, de...

Clean-in-place system for diverse processing needs

Ensure the precision and consistency of your cleaning cycles with a ro...

Weighing conveyor for consistent product flow in food processing

Ensure uniform product distribution and precise weight ...

Powder can seamer for nutraceutical and beverage powders

Achieve precision and hygiene with this can seamer designed for ...

In-line vacuum powder filler

Optimize your production line with precise, contamination-free filling for nutritional powders,...

Basket tracking system for automated batch retort systems

Efficiently manage and monitor your batch processing with a sy...

Ergonomic melt systems for solid food and personal care products

Eliminate manual lifting and enhance safety by integrat...

Vacuum gassing seamer for infant formula packaging

Ensure low residual oxygen levels in your powdered products with a spe...

Vacuum powder filler for dairy and pharmaceutical products

Achieve precision and maintain product integrity with a versa...

Powder induction system for efficient liquid powder mixing

Achieve precise and dust-free powder incorporation into liqui...

Automated scoop insertion system for powder containers

Streamline your container filling operations by ensuring precise s...

Heat exchanger for high viscosity products

For processors handling high viscosity products or those with fiber content, th...

Magnetic onion peeler for high-yield production

Achieve high yields and superior hygiene in onion processing while seamles...

Sweet pepper decorer

Streamline your sweet pepper processing with a high-speed solution that efficiently removes cores, clean...

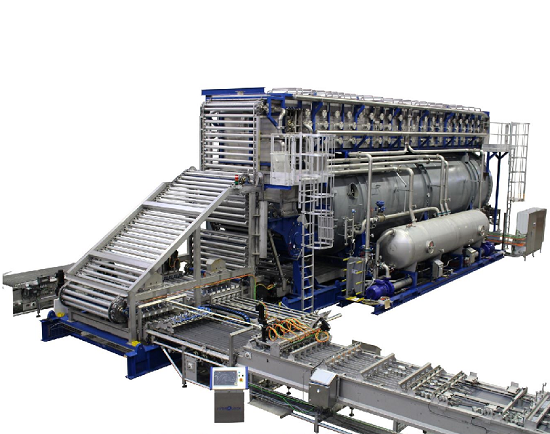

Hydrostatic sterilizer for continuous food processing

Maximize your production line’s efficiency with a continuous ...

Multi-purpose laboratory sterilizer for food processing

Achieve precise thermal process design and flexibility with a ste...

Gentle can handling ejector for rotary cooker

Achieve seamless can transfer and sterilization with reduced damage during h...

Low energy suction system for food processing retorts

Optimize your sterilization process with innovative suction technol...

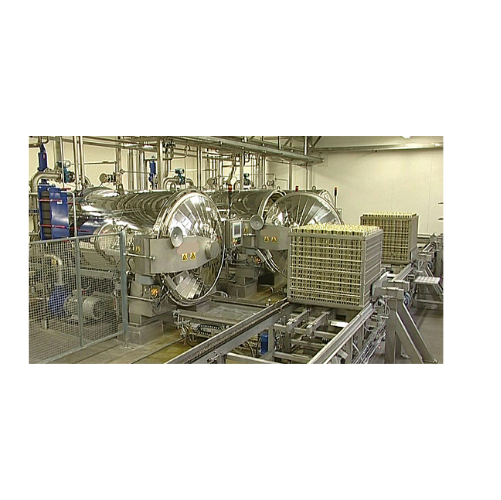

Steam water spray retort for shelf-stable food processing

Ensure uniform heat distribution and precision control in ster...

Agitating batch retort for food sterilization

Ensure superior heat distribution and precise control in your sterilization ...

Uht sterilizer for dairy and high-viscosity products

Optimize your production of dairy alternatives and fruit-based drink...

Automated batch retort system for food sterilization

Optimize your sterilization process with seamless transportation fro...

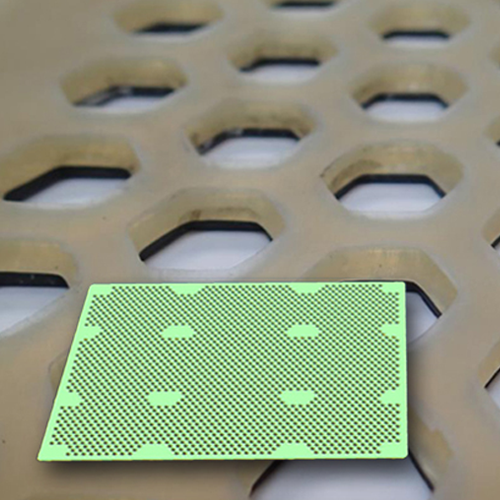

Efficient agitation system for retort packages

Enhance product quality and reduce processing time with this advanced agita...

Layer pad for agitating retorts in food processing

Efficiently secure and process irregularly shaped containers in retort...

On-food traceability technology for produce

Enhance your product authenticity with a revolutionary traceability technology...

High speed fruit and vegetable juicer

Optimize your production with a high-capacity juicer designed to efficiently process ...

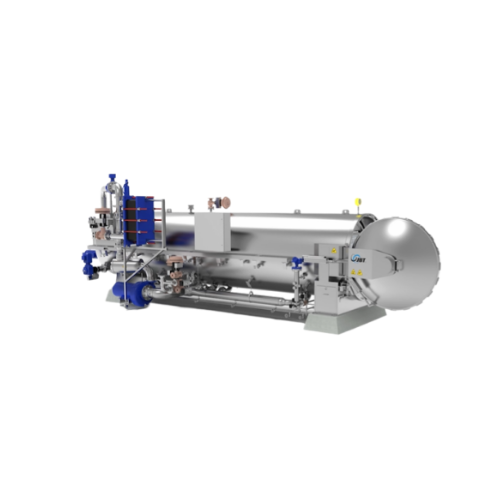

Expandable high pressure processing system

Optimize your production line with an expandable high-pressure processing syste...

High pressure processing water filtration system

Ensure super clear water after high pressure processing to protect your s...

High pressure food processing solution for medium-scale producers

Achieve reduced operational costs with high-pressure ...

High pressure processing for diverse food products

Maximize production versatility and ensure product safety with a high-...

Knocker conveyor for fresh produce processing

For processors dealing with mixed produce, this conveyor effectively separat...

Preparation line for fresh produce

Streamline your fresh-cut processing with this efficient preparation line, facilitating ...

Fresh cut produce tray sealer

Ensure freshness and extend product shelf life with a flexible sealer designed for varied pack...

Fruit and vegetable shelf life extender

Extend the freshness and appeal of your produce with our innovative dipping solutio...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Rotary can filler and closer for metal cans

Achieve seamless integration in your production line with a solution that sinc...

Volumetric filler for various food products

Achieve high precision and flexibility in your filling processes with a volume...

Forced circulation evaporator for tomato and fruit paste

Optimize your high-viscosity tomato and fruit paste production w...

Aseptic filler for packaged dairy and beverages

Ensure product sterility and extend shelf life efficiently with high-speed...

Can seamer for high-speed liquid applications

Ensure consistent seal integrity and maximize throughput with this advanced ...

Uht plant for aseptic product treatment

Ensure optimal product quality and production safety with versatile UHT solutions f...

Continuous leveler and sealer for powder packing

Enhance efficiency in powder packaging with a system that ensures precise...

Vacuum juicing for fruits and vegetables

Achieve superior juice quality with minimal oxidation and maximum nutrient retenti...

Rotary tampers for metal and glass containers

Optimize your food production line with high-speed rotary tampers, designed ...

Large production autoclaves for laboratory and pharmaceutical use

Enhance your production line with our large autoclave...

Rotary vacuum fillers for liquid and semi-liquid food products

Achieve precise filling of a wide range of liquid and sem...

Ultraclean filling monoblocks for food industry

Enhance product safety and quality with monoblocks designed for ultraclean...

Rotary piston fillers for pumpable products

Optimize high-speed production lines with precision filling for diverse liquid...

Rotary piston fillers with plunger for viscous products

Optimize your filling process with high-speed, rotary piston fill...

Mixing vessel for liquid, sauce, and cream products

Maximize efficiency in your production line with a versatile solution...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

High-speed mixer for industrial mixing applications

Achieve rapid, consistent mixing and dispersion across diverse materi...

Efficient ribbon mixers for precise powder blending

Achieve consistent and uniform blending with this advanced U-Trough m...

Double cone mixer for free-flowing material blending

Optimize your production with precision blending and gentle drying o...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Batch-type single shaft mixers with bomb-bay discharge

When you need rapid, residue-free discharge in your batch mixing p...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Vibro-aerators for bulk solids discharging

Optimize your powder flow and ensure consistent discharge with this advanced ae...

Food-grade tubular screw conveyors

Ensure complete hygiene in your production line with these stainless steel tubular screw...

Food-grade stainless steel tubular screw conveyors

Ensure contamination-free material handling with our tubular screw con...

High flow rate Fibc dischargers for wastewater treatment

Optimize your material handling with efficient, dust-proof disch...

Manual bag opener for bulk solids discharging

Effortlessly open and empty bags while containing dust emissions, ensuring a...

Industrial vibrator for high-frequency vibration

Achieve efficient material flow and compaction across various production ...

Rotary turbine vibrators for bulk solids discharging

Enhance the efficiency of material handling with high-speed, low-noi...

Rotary turbine vibrators for material flow aid

Optimize your production efficiency with high-speed, silent operation vibra...

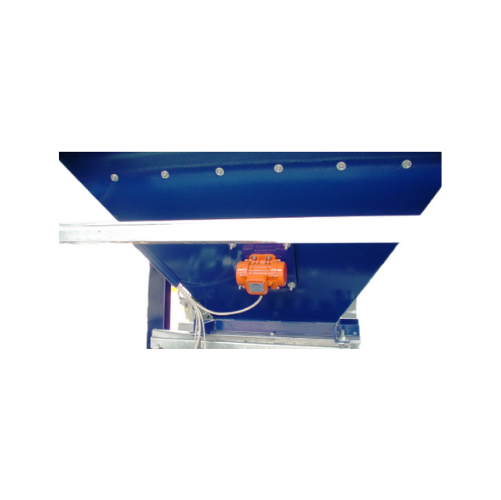

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Micro-batch feeders for powder and granular material

Struggling with clog-prone powders? Gain precise control and consist...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Cushioned pneumatic vibrators for bulk solids conveying

Streamline your material handling with precision vibration contro...

Waste bag compactor for bulk solids

Efficiently compact waste bags to a fraction of their volume, streamlining disposal whi...

Vibratory outlet hopper for bulk material discharge

Struggling with material bridging and inconsistent discharge? Enhance...

Food-grade bin activator for optimized material flow

Ensure hygienic and efficient discharge from hoppers with our food-g...

Food-grade bin activator for hygienic bulk solids discharge

Achieve consistent material flow and avoid contamination wit...

Rotary bin discharger for bulk solids

Efficiently manage bulk solids with a rotary bin discharger that minimizes residue an...

Stand-up pouch filling and sealing system

For packaging lines that demand quick, efficient, and flexible pouching, this hi...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Stand-up pouch packaging for various products

For manufacturers seeking versatile packaging solutions, this machine delive...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Horizontal flat pouching system for up to 180ml capacity

Optimize your packaging process with a high-speed solution desig...

Vibratory hopper for bulk solids discharge

Ensure consistent material flow and prevent bridging in storage silos with this...

Bin activator for silo and hopper discharge

Ensure optimal material flow and prevent blockages in your storage systems wit...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Side-mount agitator for large tank mixing

Achieve efficient mixing in large tanks with reduced energy consumption by lever...

High-speed vertical form fill seal for various packaging needs

Streamline your packaging process with an advanced vertic...

Clean-in-place (cip) system for sanitation processes

Ensure thorough sanitation in your production line with a streamline...

Industrial milling systems for food processing

Streamline your food production line with robust milling and cutting soluti...

Multifunctional industrial food mixer

Efficiently handle complex food processing tasks from mixing to homogenizing with a m...

Multifunctional cheese and sauce processor

Optimize your production of sauces, dressings, and confectionery fillings with ...

Multifunctional industrial mixer for processed cheese and sauces

Optimize your batch production with a versatile solutio...

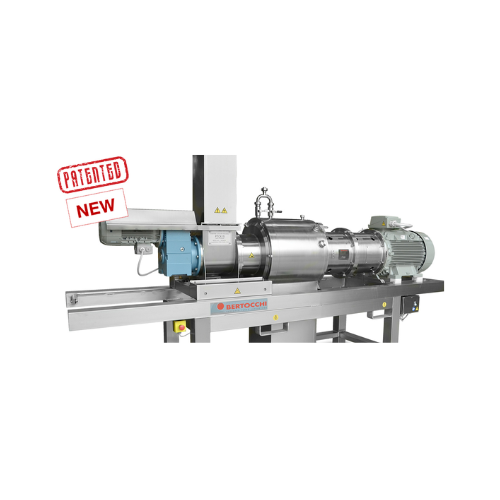

Industrial particle size reduction processor

Optimize your production line with high-capacity, continuous particle size re...

Turnkey potato flake processing line

Effortlessly transform raw potatoes into high-quality flakes with this integrated line...

Slow masticating juicer for twin gear pressing

Effortlessly create nutrient-rich juices and culinary delights with precisi...

High-speed vacuum blender for commercial use

Achieve optimal blending with cutting-edge vacuum technology, ensuring vibran...

Glass personal blender for nutrient preservation

Experience enhanced flavors and nutrient retention with advanced vacuum b...

High-speed blender for commercial use

Designed for high-performance blending tasks, this solution integrates vacuum technol...

Single-serving blender for home use

Create smooth, nutrient-rich beverages and culinary delights effortlessly, whether you&...

Single-serving blender for quick personal blends

Transform your favorite ingredients into nutritious smoothies, soups, and...

Hot cutter for processing extrudate into pellets

Efficiently transform extrudates into precise pellet sizes, enhancing you...

X-ray detection for food inspection

Ensure product integrity in high-speed packaging lines by detecting metallic and non-me...

Multifunctional cooking kettle for commercial kitchens

Optimize your batch cooking processes with an all-in-one solution ...

Commercial food mixers for versatile culinary applications

Streamline your food production with mixers and kneaders desi...

Commercial carborundum peeling system

Effortlessly peel a range of root vegetables with precision, optimizing batch process...

Versatile spray dryer for dairy and plant-based powders

Achieve precise moisture control and optimal powder functionality...

Industrial clarifier for dairy and plant-based products

Optimize your production line with cutting-edge clarification tec...

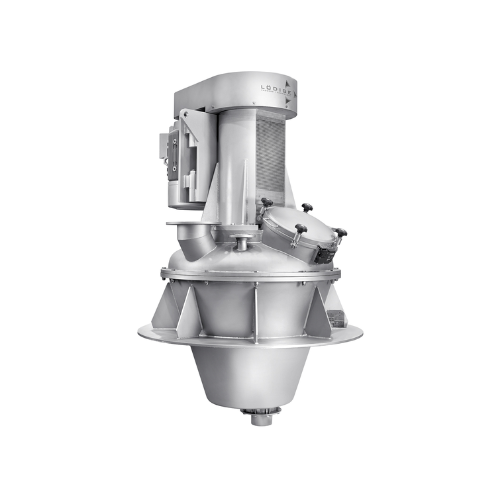

Conical homogenizer for powder and granulated products

Achieve seamless homogenization of diverse powders and granulated ...

Drum unloader for liquid ingredients

Streamline the unloading of viscous liquid ingredients with advanced water injection t...

High shear mixer for emulsions and dispersions

Achieve precise emulsification and dispersion with advanced high-speed mixi...

Tubular heat exchanger for food processing

Optimize energy consumption and ensure unparalleled food safety during heat tre...

Autonomous ingredient dissolver for high-volume dry ingredient mixing

Efficiently mix multiple high volumes of dry ingr...

Continuous flash cooler for sweetened condensed milk

Optimize your production with a continuous cooling system, designed ...

Evaporator for dairy products

Need efficient moisture removal in diverse dairy and food applications? This falling film evap...

Aseptic tank with blending function for liquid food storage

Achieve seamless integration of aseptic buffering and in-lin...

Ibc rack for storing and discharging intermediate bulk containers

Optimize liquid handling in your production line with...

Indirect Uht treatment for high viscous products with particles

Optimize your production line with a unit that ensures h...

Continuous ultra-high temperature treatment for prepared food products

Optimize your prepared food production with cont...

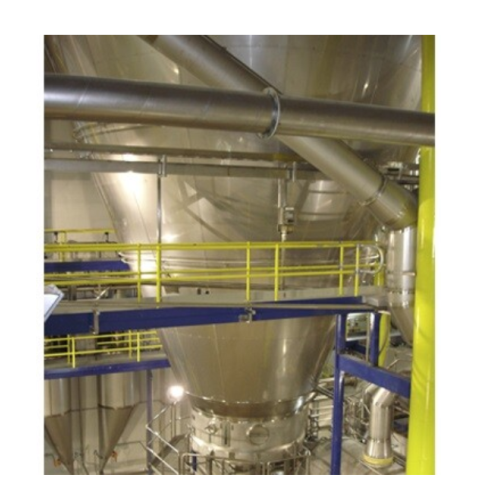

Spray dryer for nutritional powders

Ensure precise moisture control and enhance powder quality in nutritional products with...

Spray dryer for dairy, whey, and plant-based powders

Achieve precise control over powder attributes with our versatile sp...

Efficient pasteurizer for prepared foods

Achieve precise heat treatment and reduce product waste with a modular pasteurizat...

High shear mixer for dairy and beverage industry

Achieve consistent product quality with a high shear mixer, enabling seam...

Autonomous ingredient dissolver for high volume dry ingredient mixing

Streamline your production by seamlessly mixing d...

Contherm scraped-surface heat exchanger for viscous food products

Optimize your heating and cooling processes for stick...

Industrial plate heat exchanger for food processing

Ensure consistent product quality with precise temperature control an...

Tubular heat exchanger for food products

Achieve precise temperature control and energy efficiency with this innovative tub...

Low-energy evaporation system for dairy products

Enhance product quality and lower energy costs with a cutting-edge evapor...

Evaporation system for dairy products

Optimize product quality with continuous evaporation, ensuring efficient moisture rem...

Aseptic tank for blending and buffering

Optimize your production line with a secure aseptic tank that ensures precise in-li...

High-speed aseptic carton filling solution

Maximize production efficiency and meet growing demand with this high-output fi...

Filling system for gable top packages

Achieve precise, cost-effective filling with reduced energy consumption for chilled l...

Filling solution for water packaging

Achieve efficient packaging for a variety of beverages with this high-speed filling so...

Filling system for tetra brik 100 slim packages

Optimize your chilled product packaging with a high-speed filling system d...

Compact aseptic filling solution for versatile production

Maximize production line efficiency with a compact filling sys...

High-speed carton filler for aseptic packaging

Maximize production efficiency with this high-speed filling solution that e...

Aseptic filling solution for liquid food packaging

Optimize liquid food production with advanced aseptic filling, ensurin...

Vertical package accumulator for food and beverage production

Ensure seamless flow and precise order tracking of package...

Cardboard packer for secondary packaging

Streamline your packaging process with a high-speed, automated cardboard packer th...

Industrial tray shrink wrapper

Optimize your packaging line with rapid, resource-efficient shrink wrapping, accommodating di...

Manual monoblock for filling and capping spouted pouches

For those handling liquid or semi-dense products, this manual mo...

Manual filling and capping for spouted pouches

Optimize your production line with a versatile solution for filling and cap...

Manual filler and capper for spouted pouches

Easily manage filling and capping for flexible pouches with precise volumetri...

Potato masher for making mashed potatoes

Transform cooked and raw ingredients into fine, uniform purees with precision. Ide...

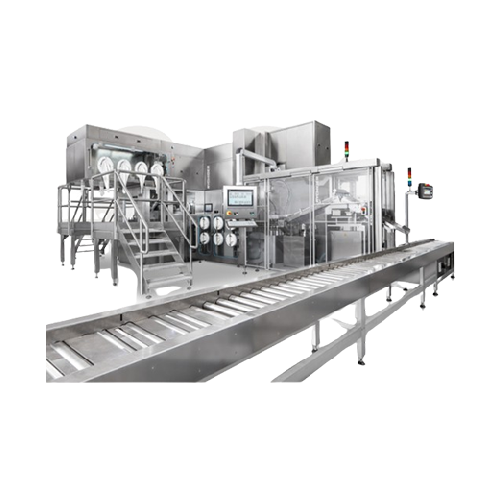

Automated cup filling solutions for liquid and viscous products

Ensure precise and hygienic filling of dairy, baby food,...

Cascading water sterilizer for optimized food preservation

Reduce sterilization times significantly while preserving foo...

Laboratory pilot sterilizers for food packaging

Optimize your R&D with precise sterilization and heat treatment capab...

Static air steam sterilizer for agri-food products

Efficiently sterilize diverse packaging types with precise temperature...

Cascading water autoclave for food sterilization

Streamline your food sterilization process with an energy-efficient autoc...

Shear pumps for continuous on-line dispersion

Effortlessly achieve consistent shearing and mixing with versatile shear pum...

Tubular juice pasteurizer

Ensure optimal safety and quality of liquid products with precise temperature control and high hea...

Deaerator for liquid food products

Enhance product quality by efficiently removing air and preserving vital aromas in liqui...

High pressure homogenizers for dairy and pharmaceutical applications

Optimize your production line with high-pressure h...

High pressure homogenizer for dairy and food processing

Achieve uniform particle size and enhance product stability with ...

High pressure homogenizer for dairy and pharmaceutical industries

When uniform texture and stable emulsions are critica...

Scraped surface heat exchanger for high-viscosity products

Designed for handling high-viscosity products, this system en...

Batch powder mixer for circulatory dispersion

Optimize your batch production with a powder mixer designed for efficient di...

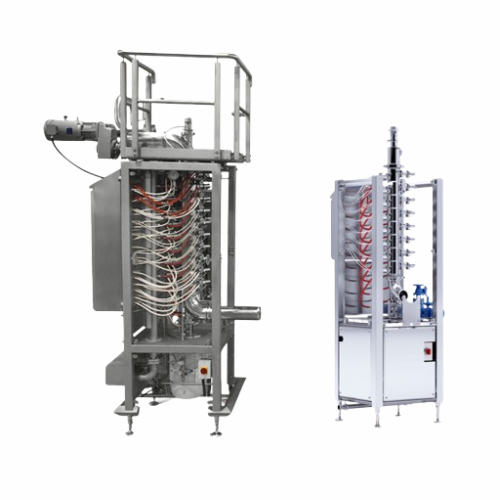

Instant infusion Uht for baby food or milk concentrate processing

Achieve exceptional product quality with ultra-short,...

Milk pasteurizer system

Ensure your dairy and plant-based beverages achieve optimal safety and quality with precise temperatu...

Pilot plant homogenizer for immiscible liquids

Streamline your R&D with precise homogenization, allowing you to test ...

Multipurpose ultra high temperature (uht) pilot plants

Optimize liquid food production with a versatile pilot unit design...

Sanitary gasketed plate heat exchangers for clean applications

Ensure product purity and maintain hygienic standards wit...

High pressure homogenizer for food and beverage processing

Optimize your production line with a versatile high-pressure ...

Hygienic tanks for various processing needs

Achieve optimal processing and storage with customizable hygienic tanks, desig...

Infusion Uht system for dairy and plant-based beverages

Efficiently extend the shelf life of dairy and plant-based bevera...

Small scale continuous evaporator

Ideal for lab and small-scale production, this evaporator offers precise control for redu...

Small scale spin flash dryers for high-viscosity liquids

Optimize moisture control with cutting-edge spin flash dryers de...

Tall form dryer for producing large non-agglomerated particles

Achieve precise particle size control and optimal moistur...

Spray dryers for producing free-flowing dustless powders

Achieve consistent product quality with customizable spray dryer...

Aseptic storage tank for aseptic products

Ensure uninterrupted aseptic product storage with this advanced tank system, des...

Clean in place (cip) system for industrial cleaning

Ensure optimal hygiene and production efficiency with a system that s...

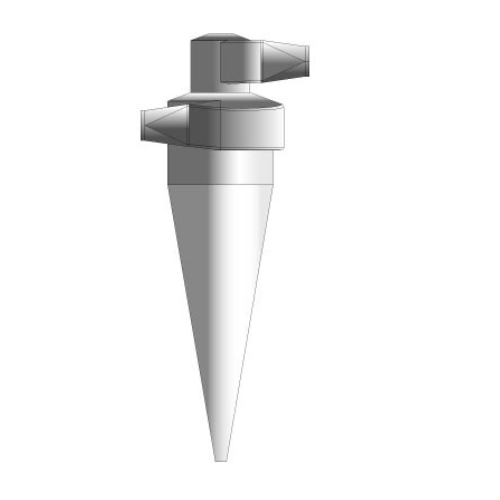

Centrifugal atomizer for precise spray drying

Achieve precise control over particle size and moisture content with centrif...

Industrial cyclone separators for air particulate removal

Optimize particulate removal in air streams with cyclone separ...

Industrial fluid bed dryers for powder processing

Enhance moisture control and uniformity in powder products with dynamic...

Small diameter vegetable peeler

Streamline your small vegetable processing with high-speed peeling, cleaning, and polishing ...

Iceberg lettuce decoring and cutting system

Optimize your salad production with precise decoring and cutting, ensuring max...

Hydrocooler for cooling baby carrots and potatoes

Ensure optimal temperature control and product quality by utilizing a h...

Laboratory scale powder/liquid mixer

Easily integrate powders into complex liquid formulations at a laboratory scale, ensur...

High shear mixer for efficient particle size reduction

Achieve rapid and precise blending and particle reduction in your ...

In-line ultra sanitary mixer for pharmaceutical and food applications

Enhance your liquid formulations with precision m...

Mayonnaise production line

Streamline your high-capacity mayonnaise production with precise mixing, emulsifying, and pasteur...

Automated sauce production lines

Streamline your sauce production with flexible lines designed for rapid recipe changeovers,...

Automated soup production line

Transform your soup production with a high-efficiency, fully automated line, seamlessly integ...

Automated mayonnaise and dressing production line

Ensure the consistent quality of your mayonnaise, dressings, and sauces...

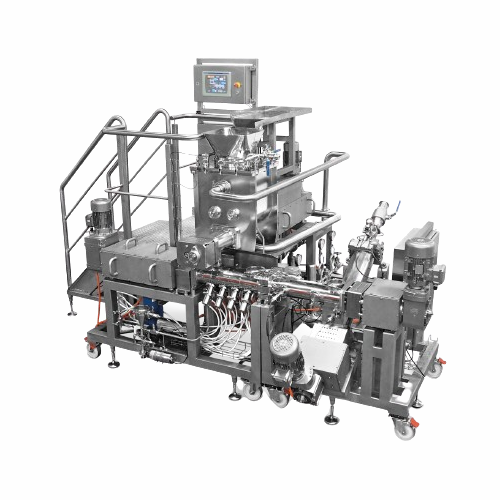

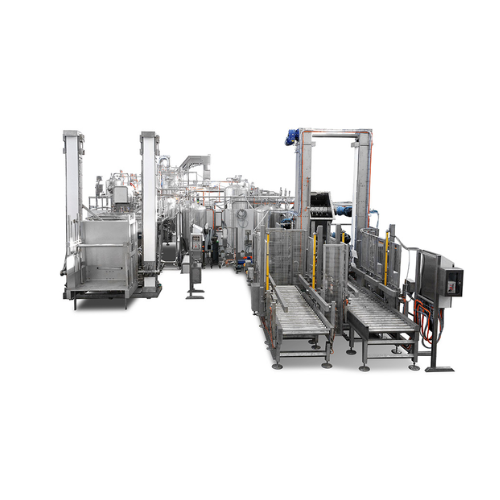

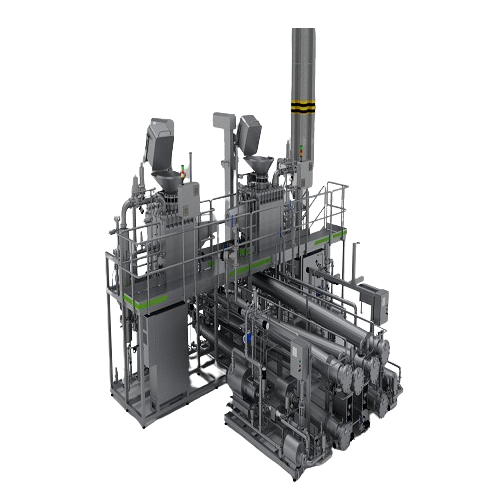

Baby food production line

Ensure optimal safety and precision with this production line, designed for processing delicate ba...

Ketchup manufacturing line

Streamline your sauce production with precision-engineered efficiency, allowing for seamless reci...

Top-loading delta robot automation solution

For high-speed operations requiring precise product handling, this top-loading...

Top loader robots for precision packaging

Optimize packaging operations with versatile robotic top loaders that achieve hi...

Tray packer for forming, loading, and sealing

Optimize your production line with a versatile tray packer designed to seaml...

Lab punching and sealing system for cleanroom conditions

Test and refine your packaging processes with precision, ensurin...

Cartoner for pharmaceutical products

Effortlessly streamline your packaging line with compact cartoning capabilities, ensur...

Sterile filling platform for pharmaceuticals

Achieve precise, high-speed aseptic filling and packaging with advanced compl...

Coffee capsule filling and sealing solution

Optimize your production with a high-speed solution designed to fill and seal ...

Coffee capsule filling and sealing system

Boost capsule production efficiency and reduce downtime with a high-speed system...

Coffee capsule filling and sealing line

Elevate your capsule production with a high-speed filling and sealing solution that...

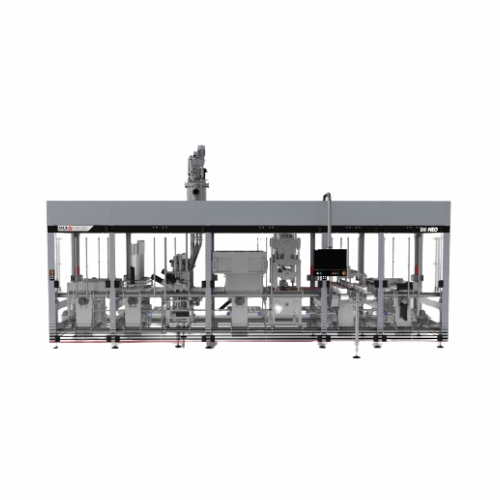

Production system for molecular diagnostics

Eliminate bottlenecks in molecular diagnostics production with a versatile sys...

Compact case packer for secondary packaging

Optimize your secondary packaging process with a case packer that operates cle...

Sequentially automated case packer for small products

Efficiently pack diverse small products into large cases with preci...

Compact palletizer for food and beverage products

Optimize your end-of-line operations with a space-saving palletizer tha...

Standardized modular tray former for secondary packaging

Optimize your packaging line efficiency with this modular tray f...

Lab device for testing coffee capsules

Achieve precise testing and reproducibility of coffee capsule parameters crucial for...

Convenience and pet food filling solution

Optimize your production line with high-speed, hygienic filling of diverse food ...

Filling and sealing solution for beverage capsules

Optimize your production with a modular capsule filling and sealing so...

Coffee capsule filling and sealing machine

For producers seeking a compact yet powerful machine, this system efficiently f...

Filling solution for powders and liquids in diagnostics

Simplify precision filling of diverse products, from freeze-dried...

Batch cooker and mixer for food and pet food production

Streamline your cooking and mixing processes with a versatile bat...

Semi-continuous freeze dryer with easy-loading

Freeze-drying is both a time- and energy-consuming process. In addition to ...

Top load Case Packer For Food Products

If you want to pack your food cartons, doy packs and pouches into regular cases, a s...

Small Scale Industrial Jam Cooker

Production of marmalades, jams, fruit concentrates, and sauces requires multiple steps. T...

Marmalade and Jam Processing Machine

When producing jams and marmalades, preserving the natural flavours, aromas and colors...

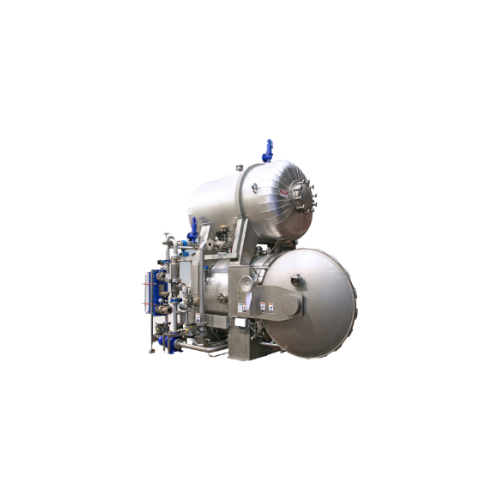

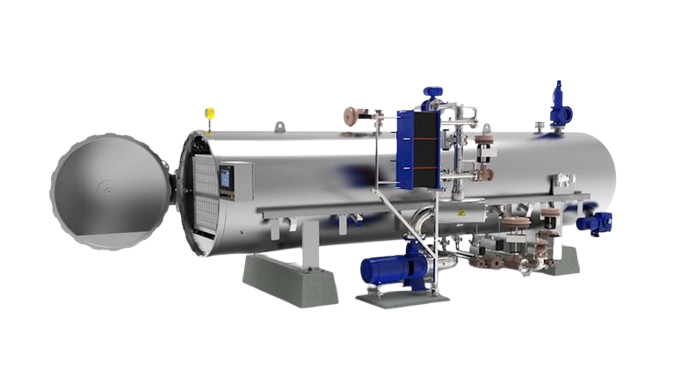

Autoclave Steam Sterilizer Machine for Ready Meals

When selecting a sterilizer for your ready meals, finding the right si...

Batch cooker for fruit puree

The fruit pulp is used in many different bakery products, especially as a filling. Since fruit ...

Concentrator for fruit puree preparation

Fruit puree is often an ingredient of various fruit-flavored yogurts, which someti...

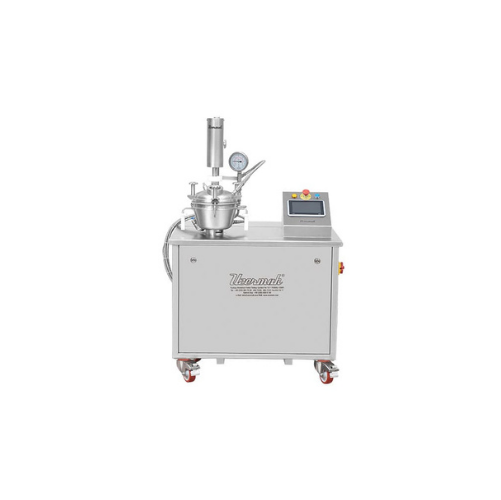

Vacuum and pressure cooker for fruits and vegetables

When producing fruit-based products such as marmalades or ice cream ...

Autoclave sterilizer for food cans and jars

An autoclave is a must-have machine for canned food production lines. It perfo...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

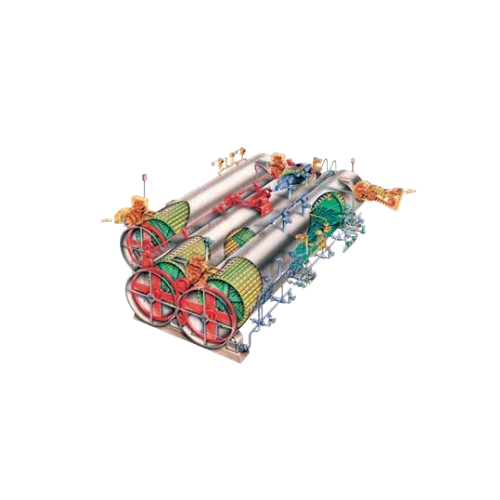

Continuous sterilizer for tin cans and jars

A concern in the coffee industry is maintaining the freshness, taste, and qual...

Continuous sterilizer for canned products

Sterilization is a critical operation in the manufacturing of canned vegetables ...

Fast gravimetric powder microdosing 50 - 200 g

Micro-dosing powders of high-value food or chemical products can be challen...

Gravimetric powder microdosing 0.400 - 2 g

If you need to process high value food, pharmaceuticals or chemicals, there is ...

Pilot scale freeze dryer

Freeze drying is a complex and time-consuming drying process which requires maintaining the quality ...

Economical Pouch Packaging Machine

The side gusset pouch is a popular packaging solution for medium formats, particularly f...

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Modular HFFS Machine

A large range of sizes and types is available, with traditional horizontal form fill and seal machines b...

HFFS machine with servo-control system

Traditional HFFS machines use mechanical cams to drive the production path through t...

High Speed Premade Pouch Packaging Machine

Pre-made pouches can be problematic for traditional cam-driven mechanical HFS m...

Retort Pouch Packaging Machine

A wide variety of products that were previously canned are now able to be more economically p...

Autoclave for canned food

Sealing and cooking products in cans, pouches or other containers is a very popular method of pres...

Industrial food processor for cooking ready meals in different consistencies

In food industry production, the developm...

Industrial vegetable cutter

Retaining freshness in cut vegetables, as well as retaining vitamins and nutrients, is a top pri...

Hygienic floor scale with lifting device

The food and pharmaceutical industries require maintaining high levels of sanitati...

Multifunctional cutting and dispersing machine

When processing alternative proteins or making products such as smoothies a...

Complete cutting, mixing, emulsifying and heating system

From laboratory scale to large volume food or cosmetic productio...