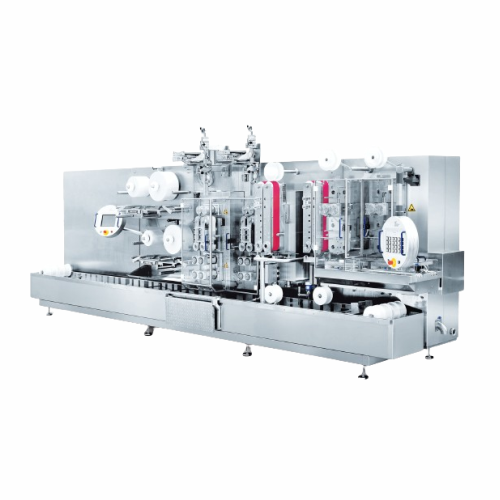

High-speed cheese slice wrapper

Achieve unparalleled efficiency with the high-speed wrapping machine that securely packages up to 2,200 cheese slices per minute while minimizing material usage and operational costs, perfect for optimizing your large-scale processed cheese production line.

Wraps and Stacks Cheese Slices Efficiently

The FreePack 2000 from the Natec Network is an innovative cheese slice wrapping machine designed to optimize the processed cheese production line. This machine operates on a continuously running production method, wrapping up to 2,200 individually-wrapped processed cheese slices per minute, allowing for high-speed operations without risking recontamination via its specialized hot-fill system. Utilizing 20% less wrapping material through efficient seam welding, the FreePack 2000 supports sustainable operations while delivering uniformly weighted slices neatly stacked for easy downstream processing.

Ideal for processed cheese manufacturers, this machine excels in various applications, including cream cheese, mozzarella sticks, and vegan cheese alternatives. The FreePack 2000 offers dual-lane operation, producing different types of cheese simultaneously with each lane capable of wrapping 1,100 slices per minute. Equipped with an intuitive central control surveillance system, it integrates smoothly into automated packaging lines, maintaining consistent output quality with minimal operator intervention.

The machine’s ability to adjust slice weight, thickness, and stack size caters to diverse product specifications, supporting flexibility in production. Compliance with CE guidelines ensures safety and quality standards, while its robust construction minimizes wear and tear, enhancing long-term operational efficiency.

Benefits

- Enhances production efficiency by wrapping up to 2,200 slices per minute, minimizing bottlenecks.

- Reduces material waste with 20% less wrapping usage due to optimized seam design, promoting cost savings.

- Facilitates seamless integration into automated lines with dual-lane operation for varied cheese types.

- Ensures consistent product quality and weight with precise control systems, minimizing giveaways.

- Complies with CE guidelines, ensuring high safety and quality standards in food processing.

- Applications

- Meat products, Soups, Sauces, Plant based, Mozzarella, Pasta filata, Specialty food, Pet food, Fruits, Processed cheese, Cream cheese, Dressings, Vegetables, Vegan, Baby food

- End products

- Vegan spread packs, Cream cheese spread portions, Alfredo pasta sauce packets, Fruit puree pouches, Baby cheese snacks, Ranch dressing cups, Tomato soup sachets, Individually wrapped processed cheese slices, Sliced deli meat packages, Gourmet pet cheese treats, Plant-based cheese slices, Artisanal cheese blends, Vegetable stir-fry packs, Mozzarella cheese sticks, String cheese

- Steps before

- Grinding, Blending / feeding, Cooking / pasteurising, Cooking / ultra high temperature, Forming, portioning

- Steps after

- Packing, Stacking, Marking

- Input ingredients

- processed cheese, cheese slices, plastic foil

- Output ingredients

- individually-wrapped cheese slices, stacked cheese slices, reduced plastic usage

- Market info

- Hochland Natec is known for manufacturing innovative engineered-to-order equipment and solutions for the dairy and food processing industry, specializing in cheese production and processing technologies, with a strong reputation for quality and innovation.

- Speed

- Up to 2, 200 slices per minute

- Capacity

- 2, 640 kg/h (5, 830 lbs/h)

- Size

- 7, 250 x 1, 320 x 2, 750 mm (285" x 52" x 158")

- Automation

- Central control surveillance system

- Utility Requirements

- 400 V, 50 Hz, 3 phase / 15 kVA

- Compressed Air Usage

- 10 m³/h at 6 bar

- Cooling Requirement

- 220 kW / 750, 700 BTU/h

- Slice Thickness

- Variable from 1.5 to 3.5 mm (0.06"-0.14")

- Slice Format

- 84x84 mm (3.3" x 3.3") excluding sealing seam

- Weight Control

- Infinitely adjustable from 13 g - 30 g (Option

- Sealing Method

- Contact free sealing

- Power Supply

- 400 V, 50 Hz, 3 phase

- Hygienic Design

- Hygienically pure water at approx. 3 °C (37 °F)

- Twin Production

- Two lanes, each up to 1, 100 slices per minute

- Stacking Height

- Max. 75 mm (3")

- Material Compatibility

- PP foil, recyclable

- Working Mechanism

- Continuously operating production method

- Integrated Steps

- Cutting and stacking technique

- Batch vs. Continuous Operation

- Inline Continuous

- Automation Level

- Central control surveillance system

- Changeover Time

- N/A

- Cleaning Method

- Contact-free sealing

- Energy Efficiency

- Low operating cost, fast ROI

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- 7, 250 x 1, 320 x 2, 750 mm

- Compact Footprint

- Yes

- Control Panel Type

- Central Control Surveillance System

- Discharge Method

- Exact Stacking in Piles

- Slice format

- 84x84 mm (3.3" x 3.3")

- Slice thickness

- Variable from 1.5 to 3.5 mm (0.06"-0.14")

- Slice weight

- Adjustable from 13 g - 30 g, Option

- Twin production

- Up to 1, 100 slices per line per minute

- Control panel type

- Central control surveillance system

- Additional options

- Dosing tank, Buffer table, Inkjet printer, Metal detector