Multifunctional industrial food mixer

Efficiently handle complex food processing tasks from mixing to homogenizing with a multifunctional system designed for versatility in batch operations, ensuring precise control and high-quality end products like sauces, cheese, and baby food.

Mixes, Cooks, Cools, and Emulsifies Products

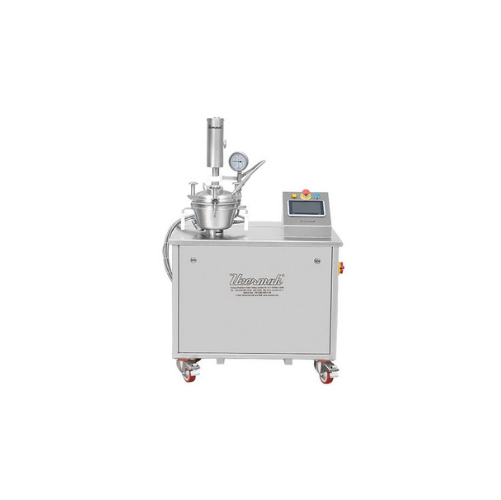

The CCM 5 from Uzermak is a multifunctional industrial mixer that excels in versatility, catering to food processing companies and dairy producers. This equipment is engineered to perform a range of tasks—including mixing, heating, cooling, and emulsifying—facilitating the production of products like cheddar cheese spread, chocolate ganache, and classic mayonnaise. Using direct steam injection and a double-jacketed bowl, it achieves efficient temperature control, accommodating batch quantities up to 2.5 liters with a maximum processing temperature of 110°C. Powered by a frequency-controlled motor, it operates between 0-3000 rpm, optimizing energy use and process precision.

Integration into production lines is straightforward, assisted by a PLC-controlled touchscreen interface for precise operation. The compact design allows for seamless incorporation into both R&D and full-scale manufacturing environments. Moreover, the CCM 5’s construction in AISI 304 stainless steel, with an option for AISI 316, ensures durability and corrosion resistance, while manual bowl and cover removal simplify cleaning and maintenance processes.

Uzermak’s mixer stands out with its adaptability across multiple sectors, from processed cheese to baby food, offering configurations tailored to your production needs, supported by comprehensive engineering consultation services.

Benefits

- Enhances production versatility by accommodating a wide range of product types and processes.

- Reduces energy consumption with efficient motor control and direct steam injection.

- Simplifies cleaning with easy-to-remove components, minimizing downtime.

- Ensures product consistency through precise temperature and speed regulation.

- Facilitates seamless integration into existing lines with user-friendly PLC operation.

- Applications

- Ketchup, Sauces, Processed cheese, Confectionery fillings, Dressings, Mayonnaise, Almond paste, Baby food

- End products

- Hollandaise sauce, Classic mayonnaise, Banana puree baby food, Blue cheese dressing, Cheddar cheese spread, Marzipan, Chocolate ganache, Tomato ketchup

- Steps before

- Ingredient Preparation, Weighing, Material Feeding

- Steps after

- Cooling, Packaging, Quality Control, Storage

- Input ingredients

- processed cheese ingredients, dressing ingredients, sauce ingredients, baby food ingredients, confectionery fillings, almond paste ingredients, mayonnaise ingredients, ketchup ingredients

- Output ingredients

- processed cheese, dressings, sauces, baby food, confectionery fillings, almond paste, mayonnaise, ketchup

- Market info

- Bowl capacity

- 5 liters

- Product processing capacity

- 2.5 liters/batch

- Processing temperature

- Max 110 °C

- Steam consumption

- 10 kg/h

- Main motor power

- 0.75 kW

- Scrapper’s motor power

- 0.75 kW

- Vacuum pump power

- 20 kW

- Automation

- PLC and touch screen

- Frequency controlled main motor

- 0-3000 rpm

- Steam filter

- Included

- Operating voltage

- 220 V

- Mixing method

- Heated mixing, cooling, grinding, emulsifying

- Cooking type

- Direct or indirect cooking under vacuum

- Vacuum capabilities

- Yes, vacuum pump included

- Automation level

- PLC and touch screen control

- Batch operation

- Batch processing

- Cleaning method

- Manual cleaning (removable bowl and cover)

- Energy efficiency

- Energy efficient operation

- Temperature control

- Max 110 °C processing temperature

- Corrosive resistance (e.g. acids)

- AISI 304/316 stainless steel

- Cleanability

- Easy to clean materials

- Biological compatibility

- Food-grade stainless steel

- Density/particle size

- 0.5–2.5 g/cm³

- Bowl capacity

- 5 liters

- Product processing capacity

- 2.5 liters/batch

- Material

- AISI 304 quality stainless steel

- Steam injection method

- Direct steam injection, 1 nozzle

- Heating/Cooling system

- Double jacket (Heating, cooling)

- Removable parts

- Manually removable bowl, manually removable cover

- Control panel type

- PLC and touch screen

- Bowl material

- AISI 304 or AISI 316 stainless steel

- Steam generation

- Built-in steam generator (optional)

- Air supply

- Built-in air compressor (optional)