Cheese forming and slicing system

Optimize your cheese production with high-speed, precision forming and slicing, ensuring safe, contamination-free processes while maximizing throughput and minimizing labor costs.

Forms and Slices High-Speed Cheese Products

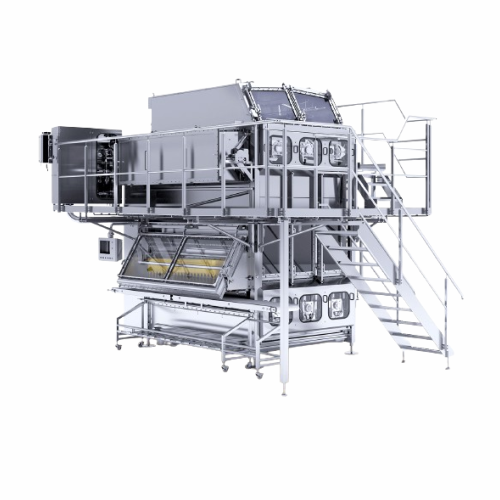

The FreeSlice 3000 from Natec Network is an innovative slicing and forming machine designed to revolutionize cheese production. By replacing traditional chill-roll systems, it offers high-speed, efficient processing with a capacity of up to 4,200 slices per minute. This machine seamlessly forms and slices processed, analogue, and hybrid cheeses into standardized products like slices, cubes, shreds, and sticks. The integrated laminar flow system ensures safe, contamination-free production, while its Clean-In-Place (CIP) capability allows for easy and thorough cleaning. With its vertical belt design, you gain flexibility in slice thickness and formats, and the equipment integrates smoothly into continuous, high-speed production lines. The FreeSlice 3000 supports diverse applications across food processing, catering to industries such as dairy, plant-based products, and specialty foods. Its robust construction adheres to USDA design principles, ensuring food safety and quality compliance.

Benefits

- Achieves high production speeds of up to 4,200 slices per minute, maximizing throughput and efficiency.

- Minimizes contamination risk with integrated laminar flow and USDA-compliant design, ensuring food safety.

- Reduces labor costs and cleaning time with a fully integrated Clean-In-Place (CIP) system.

- Offers flexibility with adjustable slice thickness and multiple cheese format capabilities.

- Ensures quick return on investment with low operating costs and efficient operating processes.

- Applications

- Meat products, Soups, Sauces, Mozzarella, Pasta filata, Specialty food, Pet food, Fruits, Plant-based, Processed cheese, Cream cheese, Dressings, Vegetables, Vegan, Baby food

- End products

- Hybrid cheese cubes, Processed cheese shreds, Hybrid cheese shreds, Slice-on-slice processed cheese, Processed cheese cubes, Analogue cheese slices, Hybrid cheese sticks, Processed cheese sticks

- Steps before

- Grinding, Blending, Feeding, Cooking, Pasteurising

- Steps after

- Packing, Stacking, Grouping

- Input ingredients

- processed cheese, analogue cheese, hybrid cheese

- Output ingredients

- Slice-On-Slice cheese, cubes, shreds, sticks

- Market info

- Hochland Natec is known for manufacturing innovative engineered-to-order equipment and solutions for the dairy and food processing industry, specializing in cheese production and processing technologies, with a strong reputation for quality and innovation.

- Speed

- Up to 4, 200 slices/minute

- Capacity

- 3, 600 kg/h (8, 000 lbs/h)

- Size (LxWxH)

- 5, 900 x 4, 100 x 4, 800 mm (233" x 162" x 189")

- Automation

- Central control surveillance system

- Energy Consumption

- 400V, 50Hz, 3 phase / 63kVA

- Compressed Air Usage

- 1 m³/h at 6 bar

- Cooling Capacity

- 240kW / 819, 000 BTU/h

- Width of Cheese Ribbon

- Up to 2, 300 mm (90")

- Cheese Slice Thickness

- Infinitely adjustable from 1.5mm - 12mm (0.06" - 0.5")

- CIP System

- Integrated CIP system

- Slicing Speed

- Up to 4, 200 slices/minute

- Product Type Flexibility

- Slice-On-Slice (SOS), cubes, shreds, sticks

- Automation Level

- Central control surveillance system

- Response Time for Changeover

- Fast with adaptable configuration

- Cleaning Method

- Clean-In-Place (CIP)

- Recontamination Prevention

- Laminar flow system

- Efficiency

- Low operating cost, fast ROI

- Flexibility in Slice Thickness

- Infinitely adjustable from 1.5mm - 12mm

- Energy Supply

- 400V, 50Hz, 3 phase / 63kVA

- Cooling Requirement

- Fresh water for cooling, 240kW / 819, 000BTU/h

- Biological compatibility

- Meets USDA design principles

- Cleanability

- Adaptable, fast CIP cleanable

- Corrosive resistance (e.g. acids)

- Suitable for processed, analogue, and hybrid cheese production

- Density/particle size

- Variable slice thickness from 1.5mm - 12mm

- CIP cleanability

- Full system

- Machine footprint

- 5, 900 x 4, 100 x 4, 800 mm (233" x 162" x 189")

- Height

- 4, 800 mm (189")

- Width

- 4, 100 mm (162")

- Length

- 5, 900 mm (233")

- Control panel type

- Central control system

- Integration possibilities

- Adaptable with various formats and slice thickness

- Clean-In-Place capability

- Fully CIP able including the laminar flow part

- Vertical design

- Flexible in slice thickness and formats

- Add-ons

- CrossCutter, FreeStacker, CubeCutter, StickCutter, Oil spraying unit, Diagonal cut device, Reject unit