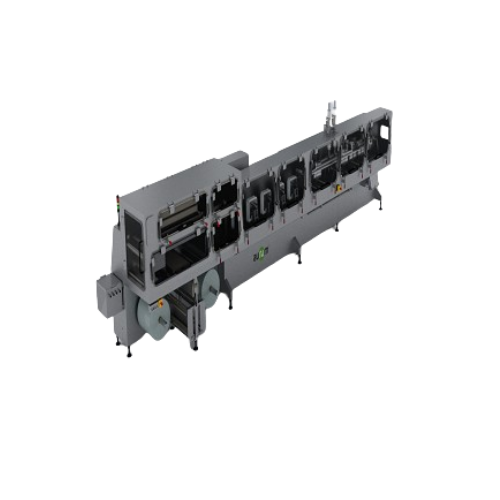

Aseptic linear doypack filler

Ensure extended shelf life and preserve quality in liquid food products with this high-speed aseptic pouch filling solution, perfect for maintaining freshness and consistency without preservatives.

Aseptically Fills and Seals Liquid Food Pouches

The AFD16 ASEPTIC from Aurum Process Technology is an aseptic linear doypack filling machine designed for the efficient packaging of liquid products. This equipment is distinguished by its automatic operation, achieving up to 80 pouches per minute through a servomechanical system for continuous film movement. It excels in aseptic processing, ensuring products like spinach soup, strawberry concentrate, and baby food vegetable blends maintain quality without preservatives. The integrated ultrasonic sensors and centralized control software streamline operations, offering ease of integration with the T-Sensation® production line. Built for the food and beverage sector, it supports productions requiring high-speed, uninterrupted, and sterile filling solutions. The machine’s triple thermal sealing and optional CIP system enhance product integrity and simplify maintenance, while its compact design aids in space-saving installations.

Benefits

- Extends product shelf life without preservatives, reducing waste and spoilage.

- Increases production efficiency with high-speed, continuous operations.

- Enhances product quality by maintaining flavor, texture, and nutritional value.

- Minimizes manual intervention, reducing labor costs through automatic film reel replacement.

- Facilitates easy integration with existing production lines via centralized control systems.

- Applications

- Sauces, Industrial vegetable processing, Broths, Convenience food, Vegetable creams, Industrial fruit processing, Infant food

- End products

- Creamy tomato bisque, Strawberry concentrate, Pea puree, Sliced peppers in sauce, Baby food vegetable blend, Tropical fruit puree, Peach fruit pulp, Mashed potato convenience meal, Spinach soup, Apricot puree, Carrot puree for infants, Pear fruit gel, Marinara sauce, Diced onion chutney, Tomato ketchup

- Steps before

- Fruit processing, Vegetable processing, Sterilization, Cooking

- Steps after

- Sealing, Packing, Cooling, Shelf-life extension

- Input ingredients

- low-acidity vegetables, diced fruit, whole fruits, fruit pulp, purée, fruit concentrates, diced tomato, tomato concentrates

- Output ingredients

- aseptic doypack pouches, sealed pouches, horizontally packaged fluid products

- Market info

- Aurum specializes in the design and manufacture of custom-engineered industrial equipment, known for their innovative solutions, high-quality craftsmanship, and reliable performance in complex projects, establishing a strong reputation in the ETO equipment market.

- Speed

- Up to 80 pouches/min

- Automation

- Servomechanical, PLC-controlled

- Film Movement

- Continuous

- Sealing System

- Triple Thermal Sealing

- Operation

- Unassisted – require film reel replacement

- Centralized Control

- Yes, with T-Sensation production line

- CIP System

- Optional

- Cooling Method

- Direct cooling

- Heating Method

- Direct steam-injection heating

- Working mechanism

- Servomechanical system

- Integrated steps

- Pouch forming and filling

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC-controlled

- Cleaning method

- CIP available

- Film centering system

- Ultrasonic sensors

- Control system integration

- Centralized control

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Single control station

- Integration possibilities

- T-Sensation production line

- Film centering system

- Ultrasonic sensors

- Film replacement

- Automatic

- Thermal sealing system

- Triple thermal sealing

- Cleaning system

- CIP return system

- Servomechanical system

- Continuous film displacement