Multifunctional batch cooker for various food products

Optimize your production line with a versatile batch cooker designed to enhance efficiency in blending and cooking across diverse culinary applications, ensuring precise temperature control and consistency in large-scale food processing endeavors.

Processes and Cooks Diverse Food Products

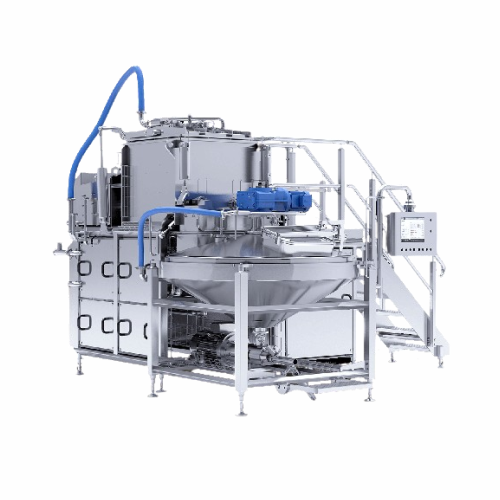

The FreeTherm 500 from Natec Network is a multifunctional batch steam cooker that excels in processing a spectrum of food products ranging from processed cheese and cream cheese to sauces, baby food, and pet food. This system stands out with its dual independently controlled augers for gentle mixing and its direct steam injection for efficient heat distribution, eliminating product hotspots. With a capacity of handling up to 2,500 kg/h, it accommodates diverse operational needs, ensuring high throughput.

Its integrated vacuum system aids in de-aeration, crucial for density control and color stability. The FreeTherm 500 supports seamless integration with upstream and downstream processes and offers full automation with programmable logic controllers for ease of operation and monitoring. Engineered from AISI 316L stainless steel, it offers excellent corrosion resistance, making it suitable for stringent food safety standards. The system’s Clean-In-Place (CIP) design ensures quick and effective cleaning, minimizing downtime.

Further customization options such as bin lifters, level measurement systems, and steam conditioning units allow tailored solutions to specific production requirements. Its design complies with global hygiene and safety standards, making the FreeTherm 500 a reliable choice for modern food manufacturing environments.

Benefits

- Maximizes production versatility with a wide range of product applications.

- Ensures consistent product quality with precise temperature control and steam injection.

- Minimizes downtime through efficient Clean-In-Place (CIP) systems.

- Enhances product quality by maintaining density and color stability with integrated de-aeration.

- Reduces operational costs with energy-efficient processing capabilities.

- Applications

- Meat products, Soups, Sauces, Mozzarella, Pasta filata, Specialty food, Pet food, Fruits, Processed cheese, Cream cheese, Plant-based products, Dressings, Vegetables, Vegan, Baby food

- End products

- Béchamel sauce, Turkey sausage, Ricotta cheese, Fresh mozzarella balls, Mascarpone cream cheese, Chicken nuggets, Rice cereal baby food, Gourmet pet food, Cheddar cheese, Caesar salad dressing, Tofu blocks, Vegetable mash, Bolognese sauce, Almond milk yogurt, Marinara sauce, Fruit puree, Alfredo pasta sauce, Organic pea baby puree, Grain-free dog kibble, Vegan cheese spread, Beet and apple specialty jam, Smoked mozzarella, Gouda cheese

- Steps before

- Transferring, Blending / feeding, Grinding

- Steps after

- Forming, portioning, Separating, Cooling, Packaging

- Input ingredients

- processed cheese ingredients, pasta filata ingredients, sauce ingredients, puree ingredients, baby food ingredients, meat ingredients, pet food ingredients, fruits, vegetables, powder and ingredient additions

- Output ingredients

- processed cheese, pasta filata, sauces, purees, baby food, meat products, pet food, specialty food, vegetable products

- Market info

- Hochland Natec is known for manufacturing innovative engineered-to-order equipment and solutions for the dairy and food processing industry, specializing in cheese production and processing technologies, with a strong reputation for quality and innovation.

- Capacity

- 500kg per batch, up to 2, 500kg/h

- Heating temperature

- Up to 98 °C (208 °F) by direct steam injection

- Automation

- Automatic programs

- Batch vs. continuous

- Batch

- CIP/SIP

- Automatic CIP

- Cleaning method

- Clean-In-Place

- Voltage

- 400 V, 50 Hz, 3 phase

- Execution

- AISI 316 L stainless steel

- Size (LxWxH)

- 4, 000 x 4, 300 x 3, 150 mm

- Batch documentation

- Included

- Working Mechanism

- Batch processing with direct steam injection

- Integrated Steps

- Mixing, heating, de-aeration

- CIP Principles

- Automatic cleaning via spray balls and integrated systems

- Batch vs. Inline Flow

- Batch

- Automation Level

- Central control surveillance system

- Flexibility

- High flexibility with multiple uses and adjustable settings

- Corrosive resistance (e.g. acids)

- Stainless steel AISI 316 L

- Density/particle size

- Variable, handles a wide range

- Heat sensitivity

- Yes/No

- Agglomeration risk

- Yes/No

- Product form

- Solid/Liquid/Paste

- Machine footprint

- 4, 000 x 4, 300 x 3, 150 mm

- Batch size

- 500 kg per batch (1, 100 lbs)

- Feed/Discharge method

- Steam injection and vacuum system with insulated buffer tank

- Contact material

- AISI 316 L (1.4044) stainless steel

- Discharge method

- Integrated with an agitator

- Construction material

- Stainless steel

- Customization options

- Bin lifter, level measurement, steam conditioning unit

- Control panel type

- Central control surveillance system

- Integration with existing CIP system

- Yes, seamless integration available

- Discharge method

- Combined discharge and CIP pump

- Different mixing auger executions

- Available depending on the product requirement

- Additional functions or different execution

- Bin lifter, Level measurement, Steam conditioning unit

- Seamless integration with UHT RotaTherm® cooker

- Available