Cheese ribbon cutting solution

Achieve precise and efficient cheese ribbon cutting with high-speed operations, ensuring perfect portioning and stacking for diverse food products.

Slices and Portions Cheese with Precision

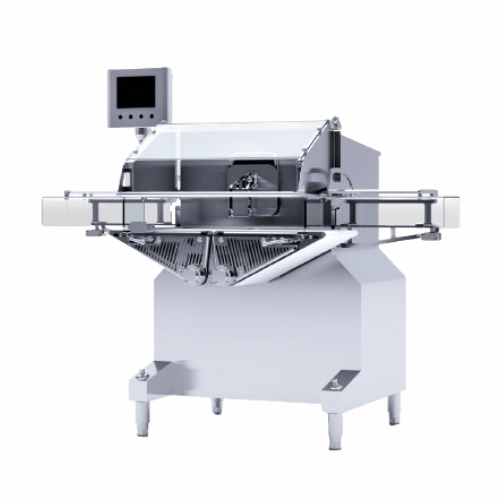

The CrossCutter XC from the Natec Network is engineered to deliver exact slicing and portioning for an array of food products, including processed and specialty cheeses. Specializing in continuous operation, this machine efficiently slices and stacks cheese ribbons, such as those from FreeSlice® systems, ensuring each cut is perfectly straight or optional diagonal without crumps. Its robust design supports high-speed cutting rates of up to 180 cuts per minute, accommodating two lanes for increased throughput. Versatile in its application, it caters to a diverse range of products from cheese slices to deli meats and plant-based foods. The CrossCutter XC integrates seamlessly into existing processing lines, positioned as a standalone unit between other machinery like the SOS Stacker or Flowpacker, facilitating both right and left production flows. Constructed to align with CE guidelines, this unit promises reliable operation with compressed air utility requirements and adjustable cutting lengths ranging from 35 mm to 305 mm. Customizable options, such as an automatic greasing system, further enhance its efficiency and adaptability, supporting your needs with extensive engineering support and compliance with food safety standards.

Benefits

- Enhances production efficiency with up to 180 precise cuts per minute.

- Supports flexible production flows with both right and left configuration.

- Maintains product quality with exact, crumple-free slicing.

- Accommodates diverse product sizes with adjustable cutting lengths.

- Integrates easily into existing lines as a standalone unit, optimizing workflow.

- Applications

- Meat products, Soups, Sauces, Mozzarella, Pasta filata, Specialty food, Pet food, Fruits, Vegan products, Processed cheese, Cream cheese, Dressings, Plant-based foods, Vegetables, Baby food

- End products

- Canned soups, Ready-to-serve pasta sauce, Cheese slices, Mozzarella sticks, Pasta filata blocks, Vegan cheese slices, Baby food pouches, Packaged pet cheese treats, Salad dressings, Plant-based cold cuts, Vegetable stir-fry packs, Sliced canned fruits, Processed specialty cheese, Cream cheese spread, Deli meat slices

- Steps before

- Slicing with FreeSlice, Stacking processed cheese ribbons

- Steps after

- Transport by conveyor belt, Stacking with SOS Stacker, Packaging with Flowpacker

- Input ingredients

- stacked cheese ribbons, processed cheese ribbons, cheese stacks

- Output ingredients

- exactly cut cheese ribbons, straight cut cheese, diagonally cut cheese, processed cheese pieces

- Market info

- Hochland Natec is known for manufacturing innovative engineered-to-order equipment and solutions for the dairy and food processing industry, specializing in cheese production and processing technologies, with a strong reputation for quality and innovation.

- Capacity

- Max. 180 cuts/min

- Cutting length

- Infinitely adjustable from 35 mm - 305 mm (1.4" - 12")

- Maximum stack height

- 100 mm (4")

- Dimensions

- LxWxH

- Power Supply

- 400 V, 50 Hz, 10 kVA

- Compressed Air Usage

- 1 m³/h at 6 bar

- Automation

- Automatic greasing system

- Optional Cutting Type

- Diagonal cut available

- Options for further functions

- Available on demand

- Compliance

- According to CE guidelines

- Cutting strategy

- Continuous inline cutting

- Cutting speed

- Up to 180 cuts/minute

- Production flow

- Right and left production flow

- Cutting type

- Straight or diagonal cuts

- Integration capability

- Standalone unit

- Automation level

- High precision cutting

- Processed cheese ribbon

- Stacked cheese ribbons

- Machine Footprint

- 1, 100 x 1, 200 x 1, 550 mm (43" x 47" x 61")

- Maximum Stack Height

- 100 mm (4")

- Cutting Length

- Infinitely adjustable from 35 mm - 305 mm (1.4" - 12")

- Execution

- According to CE guidelines

- Control panel type

- Touchscreen / PLC interface

- Integration possibilities

- Standalone / Integratable with SOS machinery

- Cutting options

- Straight / Diagonal

- Customization for production flow

- Right / Left flow compatibility

- Automatic greasing system

- Optional