Spray dryers for producing free-flowing dustless powders

Achieve consistent product quality with customizable spray dryers designed for precision drying and agglomeration, ensuring minimal residue and maximum production efficiency.

Efficiently Dries and Customizes Powder Products

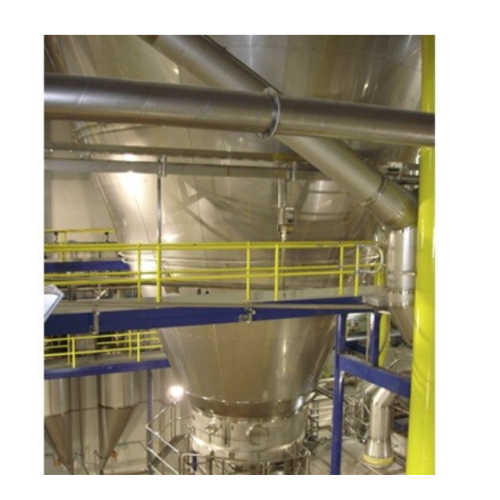

The Triple-A® Spray Dryer from Anhydro revolutionizes powder production by offering a fully customizable drying solution tailored to your specifications. It integrates an innovative spray dryer design with a fluid bed and optional external fluid bed, ensuring unparalleled control over product quality and process economy. The system excels in applications ranging from dairy powders and nutraceuticals to fine chemicals and sweeteners, producing end-products like infant formula, protein supplements, and plant-based drink powders. Capable of industrial-scale processes, it operates continuously with precision atomization and recirculation for optimal moisture control. Energy efficiency is achieved through a streamlined air distribution system that minimizes operating costs while maximizing uptime. Constructed from materials selected for durability and resistance to corrosion, it supports easy maintenance with minimal downtime. Customizable to your production needs, the Triple-A® Spray Dryer ensures consistent, high-quality powder output across diverse industries.

Benefits

- Lowers operational costs through energy-efficient drying processes.

- Enhances product consistency and quality with precise control over drying parameters.

- Adaptable to diverse production requirements, minimizing changeover times.

- Extends production runtime with reduced residue accumulation in the drying chamber.

- Offers rapid customization, ensuring alignment with specific output needs.

- Applications

- Personal care, Beverages, Plant-based drinks, Snacks, Pet food, Nutraceuticals, Pharmaceutical powder, Fine chemicals, Plant-based food, Oils, Food processing, Dairy powders, Dairy processing, Baby food, Sweeteners

- End products

- Baby food powders, Chemical reagents, Infant formula, Vitamin powders, Essential oil blends, Maltodextrin, Artificial sweeteners, Flavored beverage powders, Instant coffee powder, Plant-based protein powder, Soy milk powder, Powdered juices, Almond milk powder, Milk powder, Oat milk powder, Pharmaceutical excipients, Powdered pet food additives, Protein supplements, Snack coating powders

- Steps before

- Homogenization, Filtration, Mixing, Blending, Emulsification

- Steps after

- Cooling, Packing, Coating, Quality Assurance

- Input ingredients

- low-fat products, hygroscopic materials, sticky materials, feed material for atomization

- Output ingredients

- free-flowing powders, dustless powders, agglomerates

- Market info

- SPX Flow is renowned for its expertise in manufacturing industrial ETO equipment, specializing in fluid handling and processing solutions. They are recognized for innovation, reliability, and providing efficient solutions across diverse industries, including food, beverage, and industrial markets.

- Drying system

- Spray dryer with integrated and external fluid bed

- Air distribution system

- Controlled temperature and volume

- Airflow control

- Nozzle atomization system

- Recirculation system

- Cyclones or bag filters

- Fluid bed stages

- Second-stage integrated and third-stage external

- Product type

- Free-flowing dustless powders and agglomerates

- Capacity

- Customizable to requirements

- Cleaning method

- Minimal residue ensuring longer time between CIP

- Cooling option

- Low-impact drying and cooling options

- Working mechanism

- Spray drying with integrated fluid bed

- Integrated steps

- Spray drying, fines recirculation, fluid bed drying/cooling

- CIP principles

- Longer production time between clean-in-place

- Batch vs. continuous operation

- Continuous operation

- Air distribution control

- Constant air flow at controlled temperature and volume

- Automation level

- Integrated process control

- Product customization

- Customized according to customer specifications

- Corrosive resistance

- e.g. acids

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Customizable

- Spray dryer shape

- Cylindrical/Conical

- Feed/discharge method

- Integrated fluid bed

- Nozzle atomization system

- Customizable

- Air distribution system

- Customizable

- Exhaust system

- Cyclones/Bag filters

- External fluid bed

- Optional/Customizable

- Air distribution system

- Constant airflow with control temperature

- Nozzle atomization system

- Total control over air distribution and particle size

- Integrated fluid bed options

- Second-stage drying and cooling

- External fluid bed options

- Third-stage drying and cooling with vibratory options

- Exhaust system

- Cyclones or bag filters for fines re-circulation

- Configuration options

- Customized according to capacity, residence time, and temperature constraints