In-line checkweighing and printing system for cartons

Ensure precision and efficiency in your packaging line with a compact system that integrates checkweighing, printing, and verification, optimizing space without sacrificing throughput.

Weighs, Prints, and Verifies Carton Packaging

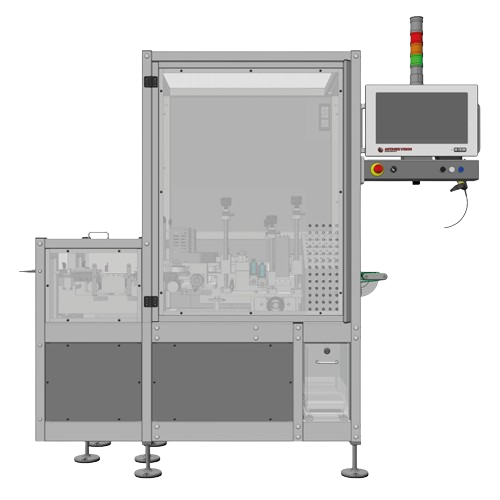

The Print & Check Checkweigher VM0600 from Antares Vision Group is a compact module specifically designed for in-line and off-line carton packaging processes in industries such as pharmaceuticals and cosmetics. This multifunctional equipment integrates checkweighing, printing, and verification in a single unit, offering substantial space savings while maintaining high throughput. It operates at speeds up to 300 pcs/min, accommodating various carton sizes. The fin-belt conveyor system ensures precise positioning during operation.

Equipped with Thermal Inkjet (TIJ) or laser printing technology, the VM0600 prints on up to three carton sides, making it suitable for blister packs and vitamin supplement boxes. It provides rigorous inspection capabilities, including 1D/2D code recognition and print quality evaluation, ensuring compliance with industry standards. The checkweigher unit features an electromagnetic compensation weighing cell, maintaining accuracy with a standard deviation of 0.15 g.

The VM0600 supports easy integration into existing production lines with its single HMI for managing all installed functions. Configurable to suit specific product formats, it maximizes efficiency and reliability, allowing pharmaceutical manufacturers and packaging companies to meet stringent packaging requirements.

Benefits

- Enhances production efficiency by integrating weighing, printing, and verification in one compact unit.

- Ensures product compliance with high-precision data verification and code recognition.

- Increases throughput with speeds up to 300 pcs/min, minimizing bottlenecks in production.

- Provides flexible integration with customizable settings and format adaptability.

- Reduces space requirements in production lines with its multifunctional design.

- Applications

- Medical devices, Nutraceuticals, Cosmetics, Food packaging, Carton packaging, Pharmaceuticals

- End products

- Cosmetic cream boxes, Printed carton boxes, Packaged snacks, Blister packs for pills, Medical tubing packaging, Vitamin supplement boxes

- Steps before

- Carton Filling, Label Design, Pre-Printing Verification

- Steps after

- Final Packaging, Product Distribution, Quality Assurance Check

- Input ingredients

- cartons, ink cartridges

- Output ingredients

- weighed cartons, printed cartons, verified cartons, labeled cartons

- Market info

- Antares Vision is renowned for providing inspection, track and trace, and quality control systems primarily to the pharmaceutical, food, and beverage industries, ensuring product integrity and supply chain transparency.

- Line Speed

- Up to 300 pcs/min

- Working Height

- 800-1000 mm

- Conveyor Length

- 1520 mm

- Standard Belt Pitch

- 150 mm

- Standard Carton Size A

- 35-120 mm

- Standard Carton Size B

- 15-140 mm

- Standard Carton Size C

- 45-210 mm

- Printing Technology

- TIJ

- Max Resolution

- 600 dpi

- Checkweigher Standard Deviation

- 1σ 0.15 g

- Max Carton Weight

- 500 g

- Label Width

- Up to 60 mm

- External Roll Diameter

- Up to 300 mm (400 mm optional)

- Line speed

- Up to 300 pcs/min

- Batch vs. continuous operation

- Inline Continuous

- Compactness

- Space-saving integration

- Automation level

- SINGLE HMI control

- Print and check verification

- 3 sides

- Changeover time

- Varies according to format size

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Yes

- Machine footprint

- Conveyor length 1520 mm

- Machine height

- 800-1000 mm

- Standard Belt Pitch

- 150 mm

- Carton Size

- A

- Printing heads

- Up to 4

- Label width

- Up to 60 mm

- External roll diameter

- Up to 300 mm (400 mm optional)

- Internal roll diameter

- 45 or 76 mm

- Control panel type

- Single HMI to manage settings of all installed functions

- Compact footprint

- Standalone module

- Integration possibilities

- In-line or off-line checkweighing, printing, and verification

- Printing options

- TIJ 2.5 and laser systems

- Labeling options

- Thermal transfer available upon request

- Camera integration

- Up to 3 cameras for inspection