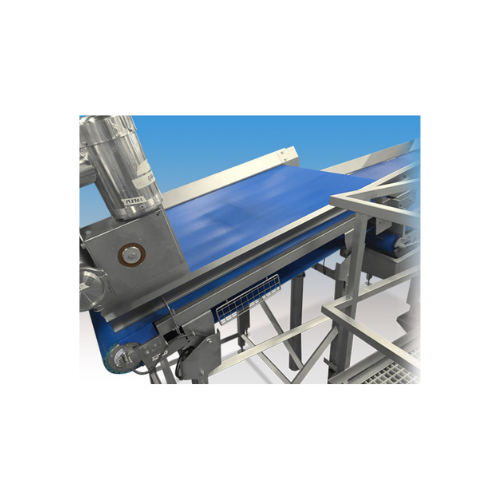

Weighing conveyor for consistent product flow in food processing

Ensure uniform product distribution and precise weight control with this technologically advanced conveyor solution, reducing production variability and enhancing quality in food processing applications.

Weighs and Conveys Fresh Produce Accurately

The FTNON Weighing Conveyor is engineered by JBT to enhance efficiency in food processing environments. This conveyor stands out by employing load cells to ensure precise product weighing and flow control, resulting in a consistent product stream ideal for integration into automated production lines. It’s particularly well-suited for applications including pureed baby vegetables, fresh salads, and ready meals like frozen lasagna and mashed potatoes. Operating seamlessly within sectors such as fresh produce and vegetable processing, the conveyor supports continuous, automated operations by maintaining accurate ingredient ratios. Constructed from hygienic stainless steel, it facilitates easy cleaning to meet stringent food safety standards. The system is adaptable to a range of solid product types, making it a versatile addition to your processing line.

Benefits

- Ensures consistent product flow to improve line efficiency and reduce bottlenecks.

- Precisely weighs ingredients, aiding in maintaining accurate recipe formulations.

- Minimizes cleaning time due to its hygienic and easy-to-clean stainless steel design.

- Enhances product quality by preventing overloading and ensuring uniform mixing.

- Supports seamless integration with existing automated systems for streamlined operation.

- Applications

- Soups, Sauces, Ready meals, Potatoes, Fresh produce, Oils, Dressings, Vegetables, Seasonings, Baby food

- End products

- Olive oil, Alfredo sauce, Fresh salad mixes, Tomato soup, Caesar dressing, Garlic seasoning, Mashed potatoes, Pureed baby vegetables, Frozen lasagna, Chopped carrots

- Steps before

- Product loading, Mixing, Portioning

- Steps after

- Packing, Labeling, Quality inspection

- Input ingredients

- fresh cut produce, vegetables, potatoes, onions

- Output ingredients

- weighed produce, constant product flow, checked product quantity

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Product Flow Control

- Constant Flow

- Load Cells

- Yes

- Material

- Stainless Steel

- Cleaning Method

- Easy to Clean

- Working mechanism

- Weighing by load cells

- Product flow control

- Constant product flow

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC-controlled

- Cleaning method

- Easy to clean

- Material of construction

- Stainless steel

- Application in process line

- Product mixture control

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel design

- Biological compatibility

- Hygienic design

- Machine footprint

- Compact design

- Material

- Stainless steel

- Hygienic design

- Easy to clean

- Discharge method

- Continuous flow

- Load cells

- Incorporated for weighing

- Control panel type

- PLC-controlled

- Material

- Stainless steel

- Integration possibilities

- Can integrate with existing processing lines

- Hygienic design

- Easy to clean

- Weighing capability

- Load cells