Convenience and pet food filling solution

Optimize your production line with high-speed, hygienic filling of diverse food products, including powders, pastes, and liquids, maintaining exceptional hygiene standards and minimizing downtime.

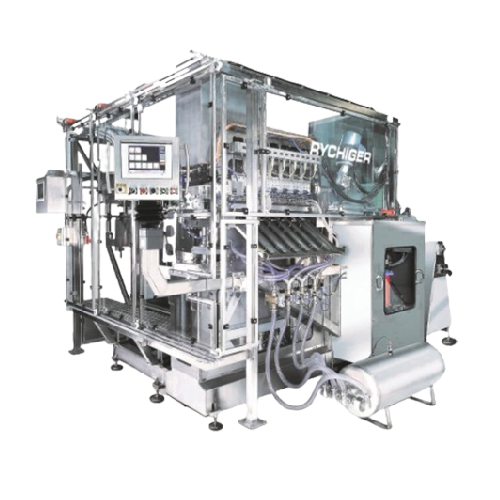

Fills, Seals, and Labels Food Products

The FS 1100 from Rychiger is a high-speed filling and sealing machine specifically designed for the food, beverage, and pet food industries. It stands out for its ability to manage various product types, including liquids, powders, pastes, and solids, maintaining a throughput of up to 600 units per minute. The FS 1100 excels in integrating a modular design with a walking beam transport system, minimizing product spillage and maintaining high hygiene standards. Its capability to handle a diversity of container materials and shapes makes it ideal for producing wet cat and dog food, instant soups, ready-to-eat meals, and more. It features automated operations controlled by modern PLC systems, promoting efficient line integration. This machine prioritizes easy maintenance with its open design for wet cleaning, which is rarely needed due to its preventive design features. Additionally, Rychiger offers comprehensive engineering support for customizations to meet specific operational requirements.

Benefits

- Achieves high production efficiency with up to 600 units per minute.

- Ensures optimal hygiene with a walking beam transport system preventing product spillage.

- Reduces cleaning downtime due to its open design, facilitating easy maintenance.

- Versatile handling of diverse container shapes and materials, suitable for a wide product range.

- Minimizes operational costs through automation and efficient energy use.

- Applications

- Supplements, Snacks, Convenience food, Pet food, Powders, Pastes, Solids, Baby food, Dairy products, Liquids

- End products

- Energy bars, Infant cereal, Granola bars, Pudding, Tomato paste, Wet cat food, Instant soup, Yogurt, Protein powder, Peanut butter, Cheese spread, Nutritional shakes, Ready-to-eat meals, Liquid meal replacement, Wet dog food

- Steps before

- Ingredient preparation, Blending, Mixing

- Steps after

- Sealing, Labeling, Secondary packaging, Tertiary packaging

- Input ingredients

- powders, liquids, pastes, solids, containers

- Output ingredients

- convenience food, pet food, filled containers

- Market info

- Rychiger is known for engineering high-precision filling and sealing machines for the food and medical industries, offering customized, innovative automation solutions, with a strong reputation for reliability and exceptional engineering expertise in the packaging sector.

- Machine speed

- 45-50 cycles/min

- Capacity

- 600 units/min

- Output/hour

- 16, 200-36, 000 units/h

- Number of lanes

- 6 to 12 lanes

- Unit height

- 110 mm

- Outer unit diameter

- 55-130 mm

- Size (LxWxH)

- Depending on machine design

- Weight

- 10, 000 kg

- Connected load

- 3 x 400 V + Pe / 50 Hz

- Rated power

- 25-50 kW

- Compressed air requirement

- ≥ 5 bar, 10 l/min

- Cooling water requirement

- 3-5 l/min

- Filling capability

- Powders, liquids, pastes, solids

- Working mechanism

- Walking beam transport system

- Automation level

- Flexible modular design

- Cleaning method

- Wet cleaning / Rarely necessary

- Batch vs. continuous operation

- Continuous

- Integrated steps

- Transport, Punching, Sealing

- Changeover time

- Minimum downtime

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Yes

- Biological compatibility

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Abrasion resistance

- Yes

- Machine Footprint

- Varies based on design

- Weight

- 10, 000 kg

- Number of Lanes

- 6 to 12 lanes

- Control Panel Type

- Modular/Customizable

- Compact Footprint

- Yes, modular design

- Control panel type

- Modular design

- Integration possibilities

- Extendable with additional modules

- Lane configuration

- 6 to 12 lanes

- Transport system

- Walking beam

- Sealing module

- Punching and sealing for perfect seal quality