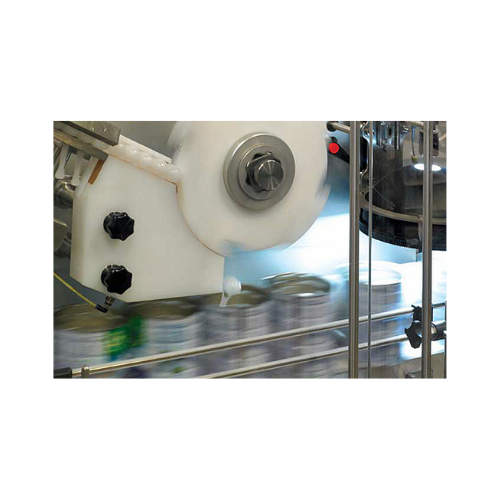

Automated scoop insertion system for powder containers

Streamline your container filling operations by ensuring precise scoop insertion for powders, reducing manual errors, and enhancing packaging efficiency.

Inserts Scoops into Powder-Filled Containers

The Scoop Inserter from PLF International is designed to tackle the complexities of precise scoop placement in powder processing industries. This machine features a unique capability to handle various scoop designs without changing parts, thanks to its adaptable bowl depth accommodation. Ideal for applications ranging from protein powder and infant formula to multivitamins and pet food, it ensures consistent packaging accuracy at high speeds of up to 240 scoops per minute. Its efficient design eliminates the need for a lubrication regime, thus reducing maintenance efforts. With the option to integrate PLF’s Camera Detection System and Reject System, you maintain stringent quality control in your operations. This system supports continuous operations, providing reliable performance in food, pharmaceutical, and packaging sectors while adhering to industry standards and regulatory compliance.

Benefits

- Increases operational efficiency with rapid, tool-free scoop changeovers.

- Minimizes maintenance costs through a zero-lubrication design.

- Enhances quality control with optional camera detection and rejection systems.

- Ensures precise dosing for powder products, improving end-product consistency.

- Supports high-speed production lines, maximizing throughput in continuous operations.

- Applications

- Supplements, Pet food, Nutraceuticals, Pharmaceutical powder, Cereals, Spices, Baby food

- End products

- Cornflakes, Dog kibble, Infant formula, Protein powder, Ground cinnamon, Omega-3 capsules, Multivitamins

- Steps before

- Filling, Powder Processing

- Steps after

- Packing, Container Inspection

- Input ingredients

- spoon-type scoop, flat disk-type scoop, container

- Output ingredients

- container with scoop

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Maximum Speed

- 240 spm

- Changeover Time

- Rapid

- Scoop Design Compatibility

- Spoon or Flat Disk

- Automation

- No change parts required for different bowl depths

- Automation level

- Manual / PLC / SCADA

- Changeover time

- Rapid changeover

- Energy efficiency

- Low power consumption

- Cleaning method

- Manual, no lubrication necessary

- Batch vs. continuous operation

- Continuous operation

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Spoon / Flat disk-type

- Container base type

- Any type of container

- Control panel type

- Touchscreen HMI

- Integration options

- PLC / SCADA

- Camera Detection System

- Optional

- Reject System

- Optional