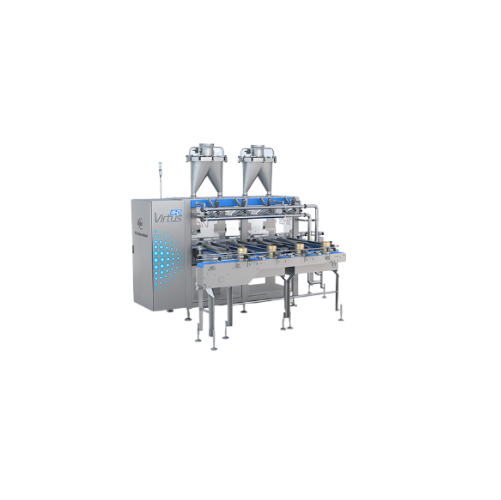

In-line vacuum powder filler

Optimize your production line with precise, contamination-free filling for nutritional powders, ensuring rapid changeovers and minimizing operational costs through innovative vacuum technology.

Fills and Packages Nutritional Powders Efficiently

The Virtus In-line Vacuum Powder Filler from PLF International is designed to meet the specialized needs of baby food, dairy, and pharmaceutical manufacturers. Its innovative vacuum filling technology ensures contamination-free, gentle handling of sensitive powders such as infant formula and nutritional supplements. Unlike traditional auger systems, it features a patent-pending nozzle design that achieves up to three times higher throughput per head, operating at speeds up to 180 cans per minute. This system efficiently integrates into existing production lines with its PLC-controlled operations and is designed for clean room use. The machine’s modular construction allows for handling a variety of container shapes and sizes, while its low-maintenance design minimizes downtime. Energy efficiency is delivered with a 50% reduction in electrical demand, alongside a 20% reduction in compressed air use. Constructed from stainless steel with FDA-approved contact parts, it aligns with EHEDG principles, ensuring compliance for the highest hygiene standards.

Benefits

- Increases production efficiency with up to three times higher throughput.

- Minimizes contamination risk through vacuum-based filling.

- Lowers operational costs with reduced energy and air consumption.

- Eases maintenance with a modular, hygienic design.

- Enhances product handling with gentle, non-contact processing.

- Applications

- Infant formula, Dairy alternatives, Specialized medical nutrition, Baby food, Dairy, Pharmaceutical

- End products

- Milk powder, Nutritional meal replacements, Protein powder supplements, Lactose-free milk, Plant-based milk powder

- Steps before

- Grinding, Mixing, Blending, Emulsification, Drying

- Steps after

- Packing, Sealing, Labeling, Sterilization

- Input ingredients

- milk-based nutritional powders, infant formula, specialized medical nutrition

- Output ingredients

- filled cans, filled glass containers, filled plastic containers, filled PET containers

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Speed

- Up to 180 cpm

- Nozzle Design

- Patent pending

- Automation

- JBT iOPS capability

- Weight Adjustment

- Individual head

- Footprint Reduction

- 30% reduction

- Electrical Demand Reduction

- 50% reduction

- Compressed Air Demand Reduction

- 20% reduction

- Material

- 304 and 316 stainless steel

- Cleaning Features

- CIP and EHEDG principles

- Container Compatibility

- Cans, glass, plastic, PET

- ATEX Approval

- Yes

- Head Models

- 1, 2, 3, 4, 6 head models

- Working mechanism

- Vacuum filling system with no moving parts

- Integrated steps

- Filling, changeover, cleaning

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- CIP - Easy clean design

- Changeover time

- Rapid changeovers

- Automation level

- Integrated JBT iOPS for real-time analysis

- Modularity

- 1 to 6 head models available

- Energy efficiency

- 50% reduction in electrical demand

- Dust control

- Dust-free environment

- Product handling

- Gentlest product handling

- Throughput

- Up to 180 cans per minute

- Corrosive resistance (e.g. acids)

- 316 stainless steel

- Biological compatibility

- FDA approved

- Cleanability

- EHEDG principles

- Density/particle size

- Varied powders

- FDA materials

- FDA approved product contact parts

- ATEX certification

- ATEX approved

- Machine footprint

- 30% reduction compared to previous models

- Discharge method

- Nozzle design, up to 3-times higher throughput per head

- Container compatibility

- Cans, glass, plastic, PET of any shape or size

- Material used

- 304 stainless steel frame, 316 st.st contact parts

- Machine modularity

- 1, 2, 3, 4, and 6 head models available

- Vacuum system

- No moving parts in contact with product

- Cleaning design

- EHEDG principles, ViwaTeq low adhesion surface treatment

- Control panel type

- PLC / HMI

- Model Options

- 1, 2, 3, 4, 6 head models

- In-line gassing system

- PLF In-Line Gassing