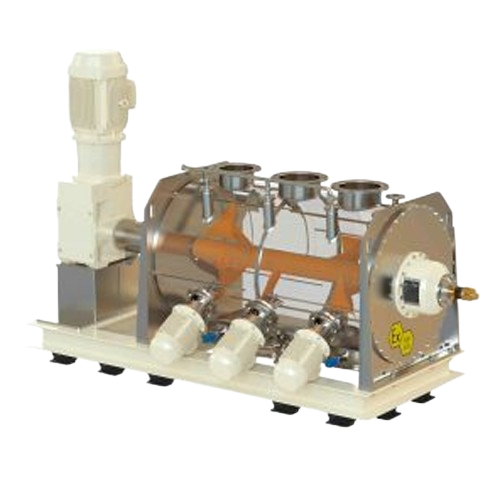

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision and speed, thanks to advanced turbulence and high-speed ploughshare technology, designed for rigorous industrial mixing demands.

Mixes and Homogenizes Solids and Powders Efficiently

The TURBOMIX (MHT) from Bachiller is a horizontal turbulence ploughshare mixer meticulously engineered for processing solids and powders. Its unique ploughshare blades operate at high speeds to achieve superior mixing, fluidification, and homogenization, catering especially to industries ranging from food and pharmaceuticals to fine chemicals. This mixer efficiently handles batch-wise and continuous production methods, accommodating capacities from 100L to 30,000L. With options for liquid injection, heating or cooling jackets, and ATEX-certified designs, TURBOMIX offers versatility and safety. Its design also includes a CE marking for compliance with the Safety for Machinery Directive 2006/42/CE. The included large lateral doors facilitate easy cleaning and maintenance, while customization options allow scaling from pilot models to full-scale production.

Benefits

- Achieves rapid mixing with short processing times, enhancing productivity.

- Ensures precise and repeatable mixing, reducing product variability.

- Minimizes operational costs through low maintenance requirements.

- Facilitates seamless integration into existing lines with scalable, batch-oriented design.

- Complies with strict industrial standards, ensuring regulatory assurance.

- Applications

- Broth, Powder detergents, Antibiotics, Toner, Paprika, Pigments, Extinguisher powder, Sweeteners, Dextrin, Cookies, Soups, Atomized detergents, Cocoa powder, Insecticides, Stearates, Herbicides, Api’s, Candies, Insoluble sugar, Spices, Vitamin complements, Flavors and aromas, Ferments, Tea, Amino acids, Titanium dioxide, Gelatin, Bakery ingredients, Enriched sugar, Milk powder, Soluble drinks, Ceramic, Special mortars, Resins, Baby food, Ready mix, Fungicides, Veterinary products, Algaecides, Fish food, Powder coatings, Food additives, Pastry ingredients, Adhesives, Food coatings, Salt iodization, Peptides, Diet food

- End products

- Dog kibble, Instant milk formula, Weed killer, Cake mix, Lemonade powder, Printer toner, Baker’s yeast, Maltodextrin powder, Curry spice blend, Abc dry chemical, Smoked paprika seasoning, Multivitamin gummies, Laundry detergent, Chocolate chip cookies, Low-calorie protein shakes, Amoxicillin capsules, Ceramic tiles, Magnesium stearate, Citrus extracts, Stevia extract, Dishwasher tablets, Uhu glue, Ibuprofen tablets, Icing sugar, Cornflakes, Instant chicken soup, Croissant dough mix, Collagen peptide, Pancake mix, Garden fungicide, Infant nutritive cereal, Polyester resin, Lime mortar, Arginine supplement, Glaze coating, Paint pigments, Earl grey tea, Gummy bears, Brown sugar splenda, Dutch process cocoa, Iodized table salt, Vegetable broth powder, Copper sulfate algaecide, Epoxy coating, Mosquito repellant, Krill meal, Marshmallow mix, White pigment for paint

- Steps before

- Drying, Grinding, Purification

- Steps after

- Packing, Coating, Granulation

- Input ingredients

- solids, powders, additives, baby food, bakery ingredients, broth, candies, cocoa powder, colorants, cookies, biscuits, dextrin, diet food, enriched sugar, ferments, fish food, flavors and aromas, food coatings, food preparations, gelatin, humid granulation, milk powder, paprika, pastry ingredients, ready mix, soluble coffee, soluble drinks, soups, spices, sweetener, tea, vitamin complements, chemical additives, adhesives, algaecides, archids, atomized detergents, carbonate, cellulose, ceramic, extinguisher powder, fungicides, herbicides, insecticides, phosphates, pigments, resins, special mortars, stearates, titanium dioxide, toner, waste, amino acids, antibiotics, API’s, aroma, feed additives, preservatives, peptides, veterinary

- Output ingredients

- mixed additives, processed baby food, blended bakery ingredients, powdered broth, coated candies, combined cocoa powder, colored colorants, compressed cookies, mixed biscuits, processed dextrin, formulated diet food, fortified enriched sugar, activated ferments, prepared fish food, infused flavors and aromas, finished food coatings, packaged food preparations, set gelatin, granulated products, blended milk powder, spiced paprika, formulated pastry ingredients, combined ready mix, brewed soluble coffee, dissolved soluble drinks/soups, blended spices, produced sweetener, infused tea, packaged vitamin complements, blended chemical additives, adhesive mixtures, treated algaecides, formulated herbicides, mixed insecticides, chemical coatings, dispersed pigments, produced resins, blended pharmaceuticals, coated powders, stabilized waste

- Market info

- Bachiller specializes in industrial engineered-to-order equipment, known for high-quality process equipment in the chemical, petrochemical, pharmaceutical, and food industries. They are recognized for their expertise in designing and manufacturing pressure vessels, reactors, and mixing equipment.

- Capacity

- 100–30, 000 L

- Mixing accuracy

- 1

- Operation type

- Batch-wise

- Mixing time

- Maximum 5 minutes

- Blade speed

- High speed centrifuging

- Automation

- Available options

- Polishing

- Internally mirror polished Ra ≤ 0.6 µm

- Liquid injection

- By spraying

- Heating/Cooling

- Jacket available

- Design pressure/vacuum

- Options available

- Sanitary design

- cGMP, validatable FDA

- ATEX execution

- Certified for internal zone 0/20

- Discharge outlet

- Wall to wall

- Continuous mixing

- Available

- Mixing type

- Ploughshare mixing

- Operation mode

- Batch-wise

- Mixing time

- Maximum 5 minutes

- Mixing accuracy

- 1

- Fluidification control

- High fluidification generation

- Inspection type

- Large lateral inspection doors

- Discharge method

- Wall to wall discharge outlet

- Continuous mixing

- Available as an option

- Automation level

- Electronic weighting and dosing systems

- Cleaning method

- Lateral inspection and maintenance doors

- Compliance,Safety

- ATEX certification, cGMP compliance

- Liquid addition

- Injection by spraying

- Abrasion resistance

- Yes

- Biological compatibility

- cGMP, FDA

- Cleanability

- Mirror polished, CIP

- Corrosive resistance (e.g. acids)

- Stainless steel

- Density/particle size

- Wide range, 0.5–2.5 g/cm³

- Machine footprint

- Compact design

- Mixer type

- Horizontal turbulence ploughshare mixer

- Capacity

- 100L up to 30, 000L

- Blade type

- Ploughshare type blades

- Operation mode

- Batch-wise operation

- Discharge outlet type

- Wall to wall discharge

- Material finish

- Internally mirror polished Ra ≤ 0.6 µm

- External finish

- Matte or mirror polished

- Inspection doors

- Large lateral inspection and maintenance doors

- Heating/cooling capability

- Heating/cooling jacket available

- Construction materials

- Stainless steel

- Application types

- Solids and powders

- Mirror Polish Finish

- Internally Ra ≤ 0.6 µm (Grit 360)

- External Finish

- Matte or Mirror Polished

- Wall to Wall Discharge

- Available