Filling solution for powders and liquids in diagnostics

Simplify precision filling of diverse products, from freeze-dried beads to liquid solutions, enhancing flexibility and throughput in your production line.

Fills Powders, Liquids, Solids Continuously

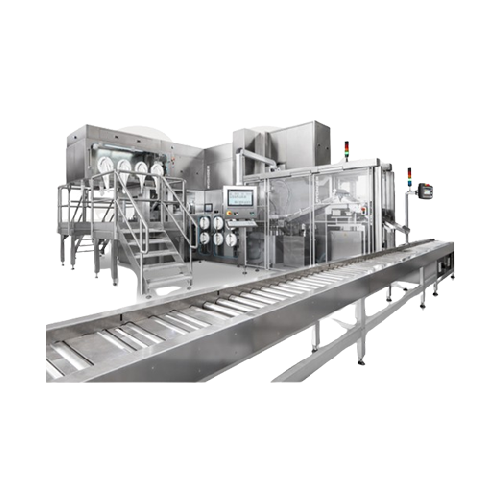

The FS 340 from Rychiger is a modular filling machine designed to manage a diverse range of filling tasks, including powders, liquids, freeze-dried beads, and bulk solids. It is particularly suited for complex applications within in-vitro diagnostics, pharmaceuticals, and food and beverage industries. Leveraging a flexible balcony design, the FS 340 supports multiple product sizes, enabling precise, high-speed filling at up to 360 units per minute. The equipment integrates seamlessly into production lines, offering continuous operation with configurable filling, punching, and sealing processes. With a PLC-controlled system, it allows for easy customization and expansion to accommodate additional processing stations, adhering to stringent production and cleaning standards. The machine’s compartments are designed for easy access and maintenance, featuring wipe-cleanable surfaces. Optional robotic handling further enhances its versatility, making it a dependable solution for high-demand manufacturing environments.

Benefits

- Enhances operational efficiency with continuous high-speed filling up to 360 units per minute.

- Offers flexibility for diverse product sizes, reducing changeover times and increasing productivity.

- Ensures stringent hygiene standards with easy-to-clean, accessible design.

- Allows seamless production line integration with customizable modular configurations.

- Minimizes manual handling through optional robotic automation, increasing safety and reducing labor costs.

- Applications

- Snacks, Cosmetics, Home supplies, Liquids, Multi beverage, Pharma, Tea, Supplements, Pet food, Bulk solids, Freeze-dried beads, Janitorial supplies, Baby food, Coffee, Confectionary, In-vitro diagnostics, Powders, Point of care, Dairy products

- End products

- Protein isolate powders, Potato chips, Cheese blocks, Chocolate truffles, Pharmaceutical tablets, Blood glucose test strips, Flavor concentrates, Powdered milk tea, Liquid concealer, Iv solutions, Liquid detergent, Cleaning powders, Medicinal freeze-dried pellets, Wet pet food pouches, Talcum powder, Tea bags, Baby formula, Diagnostic test kits, Compact foundation powders, Protein powder sachets, Instant coffee granules

- Steps before

- Material Preparation, Calibration, Container Selection

- Steps after

- Sealing, Quality Assurance, Labeling, Secondary Packaging

- Input ingredients

- powders, liquids, freeze-dried beads, larger solids, bulk solids

- Output ingredients

- sealed containers, in-vitro diagnostic kits, point-of-care testing kits, gel cards

- Market info

- Rychiger is known for engineering high-precision filling and sealing machines for the food and medical industries, offering customized, innovative automation solutions, with a strong reputation for reliability and exceptional engineering expertise in the packaging sector.

- Filling speed

- 360 containers/min

- Number of lanes

- 6

- Output/min

- 360

- Output/h

- 21, 600

- Unit height

- 70 mm

- Outer unit diameter

- 30 mm - 120 mm

- Weight range

- 3, 000 - 8, 000 kg

- Size (WxH)

- 4 - 10 x 1.8 m

- Connected load

- 3 x 400 V + Pe / 50 Hz

- Rated power

- 7 - 10 kW

- Compressed air requirement

- ≥ 5 bar, 15 l/min

- Automation level

- PLC / SCADA

- Cycle time

- 360 units/min

- Modular design

- Flexibly extendable

- Multi-product handling

- Supports powders, liquids, freeze-dried beads, bulk solids

- Processing configuration

- Configurable for different product sizes

- Cleaning method

- Easy access for cleaning

- Parallel processing

- Process two product sizes in a single production run

- Workflow integration

- From filling to punching and sealing

- Automation and handling

- Optional robot handling

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- 4 - 10 x 1.8 m

- Weight

- 3, 000 - 8, 000 kg

- Control panel type

- HMI

- Modular Design

- Yes

- Extendable Along Processing Axis

- Yes

- Integration with Robotic Arms

- Optional