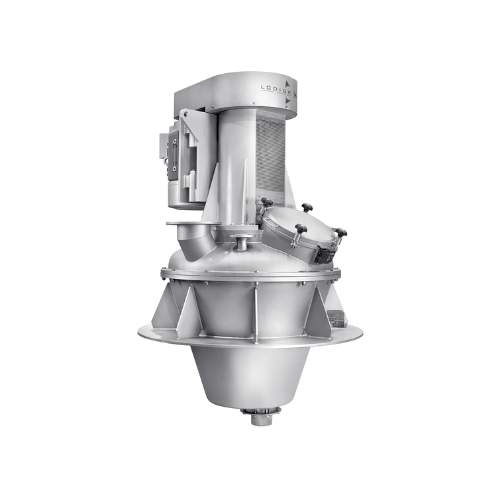

Wet mixer for viscous and paste-like products

Achieve high-quality mixing of medium to highly viscous products with precision and efficiency, ensuring thorough dispersion and consistent end results in batch processing operations.

Mixes and Dispenses Viscous and Slurry Materials

The Lödige Wet Mixer is a versatile solution from Gebrüder Lödige Maschinenbau GmbH, designed for processing viscous and slurry materials in batch operations. This vertical mixer achieves high-quality mixing through adjustable deflectors and tool configurations, ideal for industries such as food, pharmaceuticals, and chemicals. Capable of processing products like cream soups, baby formula, and active pharmaceutical ingredients, it utilizes efficient dispersion and disagglomeration to ensure uniform quality. The system supports high-speed operation with options for temperature-controlled vessel surfaces and GMP-compliant design, making it suitable for demanding environments. Constructed with high-tensile and stainless steels, it offers customizable configurations tailored to specific processing needs. With features such as a manhole for easy inspection, WIP nozzles, and CIP capabilities, maintenance is streamlined. Compliance with DIN EN ISO, ASME, and other industry standards ensures reliable operation and international approval.

Benefits

- Enhances production efficiency with high-speed mixing and systematic product movement.

- Supports diverse material processing, from food to pharmaceuticals, with customizable configurations.

- Minimizes contamination risks with WIP and CIP cleaning systems.

- Ensures regulatory compliance with GMP standards and international certifications.

- Adapts to various processing needs with adjustable vessel configurations and tool systems.

- Applications

- Soup pastes, Chemical products, Special sauces, Food products, Baby food, Plastic mixes, Pharmaceutical industry

- End products

- Cream soups, Infant cereal, Resin compounds, Nutraceutical powders, Baby formula, Food additives, Marinades, Active pharmaceutical ingredients (apis), Salad dressings, Polymer blends, Vegetable purees

- Steps before

- Grinding, Purification, Temperature Control, Preparation of Ingredients

- Steps after

- Sterilization, Packing, Quality Control, Inspection

- Input ingredients

- viscous components, paste-like products, medium to highly viscous masses, soup pastes, baby food, special sauces, plastic mixes, dry substances, liquids, greases, lecithins

- Output ingredients

- mixed medium to highly viscous masses, processed soup pastes, blended baby food, combined special sauces, homogenized plastic mixes

- Market info

- Loedige Process Technology is renowned for its expertise in industrial mixing, granulation, drying, and coating technologies, offering engineered-to-order solutions for various industries, including pharmaceuticals, chemicals, and food processing.

- Mixing system type

- Vertical

- Installation height adjustability

- Yes

- Batch process

- Yes

- Mixer vessel shape

- Conical/Cylindrical

- Mixing tool configuration

- Customizable

- Temperature control

- Available

- Product discharge

- Residue-free

- Cleaning system

- WIP nozzles

- Material transport

- Adjustable deflector

- Mixing vessel surface material

- High-tensile/Stainless steel

- GMP-compliance

- Yes

- Mixing capability

- Medium to highly viscous masses

- Process engineering tasks

- Dispersion and disagglomeration

- Product addition capability

- Dry substances, liquids, greases, lecithins

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch

- Changeover time

- Low

- CIP/SIP

- WIP

- Cleaning method

- WIP / Manual

- Energy efficiency

- High

- Abrasion resistance

- Yes

- Biological compatibility

- GMP-compliant

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steels used

- Density/particle size

- 0.5–2.5 g/cm³

- Product types

- Soup pastes, baby food, special sauces

- Machine footprint

- Compact

- Bowl shape

- Conical

- Bowl size

- Adjustable

- Control panel type

- Digital

- Discharge method

- Residue-free discharge

- Parts in contact with product

- Customer's choice

- Material

- High-tensile steels, stainless steels, special materials

- Tool systems

- Various

- Devices for adding substances

- Dry substances, liquids, greases, lecithins