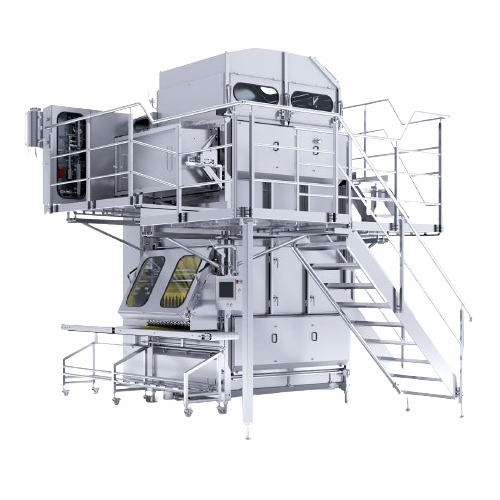

Processed cheese slice production system

Reduce recontamination risks in cheese production with a system designed for high-speed, continuous output, offering flexibility in producing various cheese formats from slices to shreds.

Forms and Slices Cheese Products Efficiently

The FreeSlice 1500 from the Natec Network is an engineered-to-order cheese processing system designed to enhance your production line. Specializing in cooling, forming, and slicing, this system produces high-quality Slice-On-Slice cheese slices, cubes, shreds, and sticks. It incorporates an integrated Clean-In-Place (CIP) system, ensuring seamless and contamination-free cleaning, and an innovative laminar flow design to prevent recontamination. Capable of processing up to 1,800 kg/h, it delivers productivity with minimal labor intervention. The system’s automation features enable efficient operation within continuous production environments, and its flexibility supports the production of processed, analogue, and hybrid cheeses, making it ideal for food, dairy, and plant-based industries. Designed to meet CE guidelines, the FreeSlice 1500 ensures compliance and reliability in diverse applications.

Benefits

- Minimizes contamination risks with integrated laminar flow and CIP systems.

- Enhances productivity and precision through high-speed, automated slicing.

- Offers flexibility for diverse cheese products, reducing need for multiple machines.

- Decreases labor costs by streamlining operation and maintenance processes.

- Adapts to various production needs with customizable slice thickness and formats.

- Applications

- Meat products, Soups, Sauces, Mozzarella, Pasta filata, Specialty food, Pet food, Fruits, Plant-based, Processed cheese, Cream cheese, Hybrid cheese, Dressings, Vegetables, Analogue cheese, Vegan, Baby food

- End products

- Hybrid cheese slices, Processed cheese shreds, Processed cheese cubes, Analogue cheese slices, Slice-on-slice cheese slices, Processed cheese sticks

- Steps before

- Grinding, Blending / feeding, Cooking / pasteurising

- Steps after

- Stacking, Grouping, Packing

- Input ingredients

- processed cheese, analogue cheese, hybrid cheese, compressed air, fresh water, coil water

- Output ingredients

- Slice-On-Slice (SOS) cheese, cheese cubes, cheese shreds, cheese sticks

- Market info

- Hochland Natec is known for manufacturing innovative engineered-to-order equipment and solutions for the dairy and food processing industry, specializing in cheese production and processing technologies, with a strong reputation for quality and innovation.

- Size

- 3, 000 x 3, 000 x 4, 100 mm (118" x 118" x 159")

- Power supply

- 400 V, 50 Hz, 3 phase / 46 kVA

- Capacity

- 1, 800 kg/h (4, 000 lbs/h)

- Slicing speed

- 2, 100 slices/min

- Slice weight

- 14 g (0.5 oz)

- Cooling requirement

- 120 kW / 307, 100 BTU/h

- Compressed air usage

- 1 m³/h at 6 bar

- Cheese width

- Up to 1, 100 mm (43")

- Cheese thickness

- 1.5 mm - 12 mm (0.06" - 0.5"), infinitely adjustable

- Cleaning method

- Integrated CIP system

- Working Mechanism

- Slice-On-Slice cheese production

- Integrated Steps

- Cooling, Forming

- CIP Principles

- Fully CIP able including laminar flow part

- Batch vs. Continuous Operation

- Continuous Inline

- Automation Level

- Central control surveillance system

- Slice Thickness Flexibility

- Infinitely adjustable from 1.5 mm - 12 mm

- Recontamination Prevention

- Laminar flow system

- Manpower Requirement

- Minimized due to integrated systems

- Cleanability

- Integrated CIP system

- Biological compatibility

- Laminar flow system

- Machine footprint

- LxWxH

- Discharge method

- Vertical design of belts

- Control panel type

- Central control surveillance system

- Control panel / HMI type

- Central control surveillance system

- Integration possibilities

- Add-ons for different applications

- Cut thickness

- Infinitely adjustable 1.5 mm - 12 mm

- Cheese format flexibility

- Slices, cubes, shreds, sticks

- Additional features

- Oil spraying unit, Diagonal cut device, Reject unit