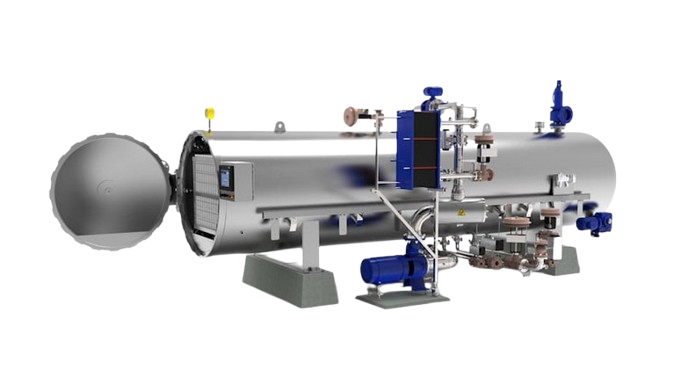

Steam water spray retort for shelf-stable food processing

Ensure uniform heat distribution and precision control in sterilization and pasteurization processes for various food and pharmaceutical products with this advanced retort system, enhancing product safety and quality while minimizing resource use.

Sterilizes and Pasteurizes Products with Uniform Temperature Control

The Static Retort – Steam Water Spray™ (SWS) from JBT FoodTech offers precise temperature and pressure control for the efficient sterilization and pasteurization of a wide range of products, including ready meals, sauces, and pharmaceuticals. By directly injecting steam and implementing water spray over the entire retort length, this system ensures fast and uniform temperature distribution. It supports batch operations with precise execution of pre-programmed recipes, making it ideal for processing beef stew, canned vegetables, orange juice, and medicinal syrups.

Designed for both solid and liquid products, the SWS retort integrates seamlessly into existing production lines. It offers automated operation with PLC controls and energy-efficient features such as indirect, sterile cooling through a plate heat exchanger, eliminating the need for water treatment chemicals. Constructed with high-quality materials, it provides ultimate container flexibility, accommodating rigid, semi-rigid, and flexible packaging. With compliance to industry standards, it ensures safe processing in food, pharmaceutical, and pet food sectors. Optional models and engineering support are available for customized configurations tailored to specific production needs.

Benefits

- Shortens processing time with uniform temperature distribution and efficient heat transfer.

- Minimizes water usage and chemical treatment needs with indirect cooling.

- Enhances product quality consistency through precise control of temperature and pressure.

- Accommodates diverse packaging types, providing flexibility across production lines.

- Reduces operational costs through automation and energy-efficient design.

- Applications

- Seafood, Ready meals, Sauces, Soups, Pet food, Fruits juices, Meat, Non-carbonated beverages, Oils, Dressings, Vegetables, Poultry, Seasonings, Baby food, Pharmaceutical

- End products

- Béchamel sauce, Beef stew, Apple puree, Dog kibble, Infant formula, Barbecue sauce, Vegetable lasagna, Chicken curry, Roasted chicken breast, Orange juice, Canned carrots, Canned tuna, Frozen peas, Clam chowder, Wet cat food pouches, Tomato soup, Sesame oil, Liquid pain reliever, Smoked salmon, Sunflower oil, Fruit smoothie, Over-the-counter cough syrup, Italian vinaigrette, Iced tea, Apple cider, Ranch dressing

- Steps before

- Filling, Seaming, Preparation, Grinding, Mixing

- Steps after

- Sterilization, Cooling, Packing, Labeling

- Input ingredients

- ready-meals, baby food, pet food, soups, sauces, mushrooms, vegetables, beans, milk, fruits juices, non-carbonated beverages, tea, coffee

- Output ingredients

- shelf-stable ready-meals, shelf-stable baby food, shelf-stable pet food, shelf-stable soups, shelf-stable sauces, processed mushrooms, processed vegetables, processed beans, shelf-stable milk products, shelf-stable fruit juices, shelf-stable beverages, shelf-stable tea, shelf-stable coffee

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Process time

- Reduced

- Heat distribution

- Efficient

- Cooling method

- Micro cooling

- Temperature control

- Precise

- Pressure control

- Precise

- Container flexibility

- Ultimate

- Steam injection

- Directly in bottom

- Batch vs. continuous operation

- Batch

- Automation level

- PLC

- Energy efficiency

- High

- CIP/SIP

- CIP capable

- Cleaning method

- CIP

- Changeover time

- Minimal

- Temperature control

- Precise

- Pressure control

- Precise

- Container flexibility

- Rigid, semi-rigid, flexible

- Corrosive resistance (e.g. acids)

- Yes

- Biological compatibility

- Food grade

- Cleanability

- CIP compatible

- Heat resistance

- Up to 135°C

- Pressure resistance

- High pressure

- Abrasion resistance

- Stainless steel construction

- Container type

- Rigid (bottles, cans), Semi-rigid (tubs), Flexible (pouches)

- Water spray distribution

- Entire shell length

- Control panel type

- HMI / PLC

- Configuration Options

- A142, A144, A146, A166, A186

- Integration possibilities

- Process Line Control, Automation

- Container flexibility

- Rigid / Semi-rigid / Flexible