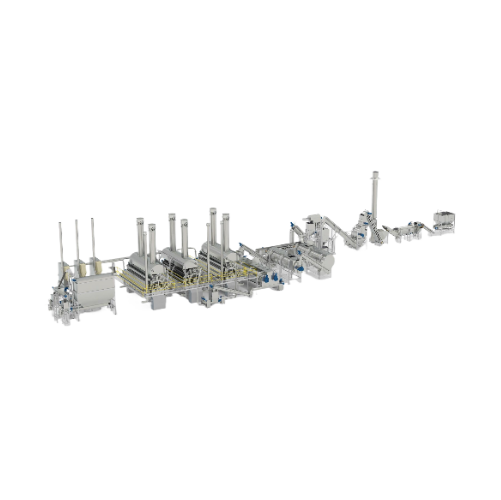

Turnkey potato flake processing line

Effortlessly transform raw potatoes into high-quality flakes with this integrated line, ensuring optimal texture and moisture levels for your final product.

Transforms Raw Potatoes into Dehydrated Flakes

The Flake line from Tummers Food Processing Solutions excels in converting raw potatoes into versatile, dehydrated products such as flakes and starch, tailored for the food processing industry. The process begins with cleaning, peeling, and cutting the potatoes, followed by precision boiling and mashing, ensuring optimal texture and stability. The core component, the Drum Dryer, evenly applies a thin layer of mash onto a heated cylinder for efficient moisture evaporation. This results in a consistent sheet of dried potato, milled to your desired specifications for applications ranging from snacks to baby food.

Designed for seamless integration, this turnkey line includes inspection belts and dosing hoppers, supported by automated lobe pumps and mill sifters, managing up to several tons per hour with continuous operation. Energy use is minimized through optimized motor control, reducing consumption significantly. Built from durable materials to withstand the rigors of industrial environments, the line complies with food safety standards, incorporating easy-to-clean features and customization options. Emphasizing sustainability, Tummers focuses on reducing waste and conserving water throughout the process, offering comprehensive engineering support for tailored solutions.

Benefits

- Enhances production efficiency with continuous, automated operation.

- Minimizes resource use, cutting energy and water consumption.

- Adapts to diverse product specifications for market flexibility.

- Simplifies cleaning and maintenance, reducing overall downtime.

- Promotes sustainability through innovative waste reduction strategies.

- Applications

- Snacks, Potato flakes, Pet food, Cereals, Starch, Baby food

- End products

- Instant mashed potatoes, Starch-enriched pet food, Dried potato flakes for snacks, Potato starch, Potato-based baby cereal, Dehydrated potato flakes

- Steps before

- Cleaning, Peeling, Cutting, Boiling, Mashing

- Steps after

- Milling, Packaging

- Input ingredients

- potatoes, foreign bodies, water, air, additives

- Output ingredients

- potato flakes, starch, mash, moisture evaporate, dried potato sheets

- Market info

- Tummers is known for its expertise in manufacturing industrial engineered-to-order equipment, particularly for the potato processing industry, including peeling, cutting, and frying systems. They are reputed for innovation, quality, and customized solutions in food processing technology.

- Boiling temperature range

- Varies by potato type

- Mashing method

- Mashing screw

- Drying method

- Drum Dryer

- Drying layer thickness

- Continuous thin layer

- Flake size control

- Sieving mill

- Pneumatic transport system

- Conditioned space

- Automation

- Turnkey

- Power consumption

- Focus on energy efficiency

- Raw material efficiency

- High

- Moisture evaporation control

- Heated cylinder

- Process Type

- Turnkey Flake Line

- Automation Level

- High/PLC controlled

- Operation Flow

- Inline continuous

- Cleaning Method

- CIP compatible

- Energy Efficiency

- Low energy consumption

- Raw Material Handling

- Direct from field or storage

- Production Capacity

- High

- Sustainability Features

- Energy, water, and waste optimization

- Production Steps

- Cleaning, peeling, cutting, boiling, mashing, drying, milling, packaging

- Moisture control during drying

- Automated

- Abrasion resistance

- Yes

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- Stainless steel used

- Mashing method

- Mashing screw with special pump system

- Machine footprint

- Based on setup

- Drum Dryer

- Central component

- Discharge method

- Pneumatic transport system

- Feed method

- Special pump to drying roller

- Control panel type

- Touchscreen / Button interface

- Integration possibilities

- SCADA / PLC

- Modular components

- Drum Dryer / Inspection belt / Dosing hopper

- Scalability

- Customizable capacity