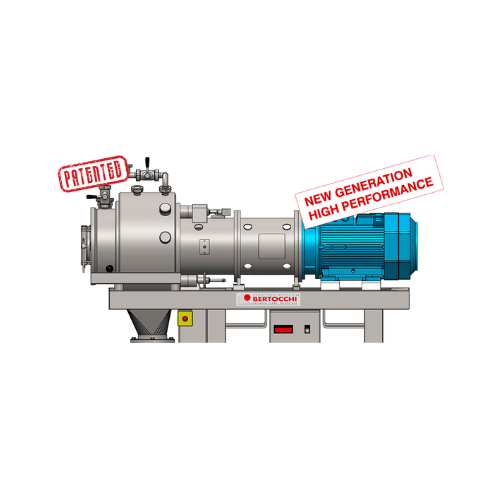

Turbo extractor for tomato and fruit puree processing

Optimize your production line with high-capacity turbo extraction for seamless puree and sauce creation, addressing the need for efficient processing of tomatoes, fruits, and vegetables with precision and speed.

Extracts and Processes Purees, Sauces, and Concentrates

The ULTRA HX Turbo Extractor series from Bertocchi represents a leap forward in processing efficiency for food production, particularly in tomato, fruit, and vegetable sectors. This machine utilizes an advanced extraction and refining process, equipped with an alveolar and hypocycloidal rotor, to handle a diverse range of products. Ideal for producing high-quality purees, sauces, and concentrates, it operates continuously with high throughput, processing up to 200 tons per hour.

Automation is seamlessly integrated with PLC controls, allowing for remote monitoring and ensuring effective operation across various stages of production. The system’s energy efficiency is enhanced by optimized motor controls, allowing for significant reductions in power consumption. Constructed from durable materials, the ULTRA HX is designed to withstand the demands of high-capacity processing lines while maintaining compliance with industry standards.

The extractor’s easy-to-clean design includes a CIP system, facilitating quick and thorough sanitation between batches, which is crucial for maintaining product quality and meeting strict hygiene standards. Customizable features and strong engineering support ensure this equipment can be tailored to meet specific processing requirements, making it a versatile addition to any production line dedicated to the creation of purees, baby foods, and fruit nectars.

Benefits

- Enhances productivity with high-capacity processing up to 200 tons per hour.

- Optimizes energy use with advanced motor control, reducing power costs.

- Ensures product quality with CIP system facilitating fast, effective cleaning.

- Tailors to specific processing needs with customizable features.

- Streamlines operations with integrated, remote-monitored PLC control system.

- Applications

- Sauces, Tomato processing, Baby food, Fruit processing, Nectars, Concentrates, Purees, Vegetable processing

- End products

- Peach puree, Apple puree, Aseptic-packed tomato concentrate, Banana puree, Baby food apple sauce, Peach nectar, Wild berry juice, Apricot nectar, Aseptic-packed vegetable puree, Apricot puree, Tomato paste, Grape puree, Pear puree

- Steps before

- Chopping, Heating, Destoning

- Steps after

- Concentration, Packing, Aseptic Processing

- Input ingredients

- tomato, apples, pears, destoned peaches, apricots, grapes, red fruits, wild fruits, tropical fruits, bananas, vegetables, chopped products, heated products

- Output ingredients

- tomato concentrate, tomato sauce, fruit puree, vegetable puree, purée to be packed at hot temperature/aseptic, baby foods, nectars

- Market info

- Bertocchi is known for manufacturing engineered-to-order industrial equipment, specializing in custom process solutions for the food and beverage industry. They have a strong reputation for innovation, quality, and reliability in producing machinery tailored to customer specifications.

- Capacity

- 1 to 200 t/h

- Capacity (UHX for Tomato)

- 10 to 100 t/h

- Capacity (UHX HD for Tomato)

- 65 to 200 t/h

- Capacity (UHX for Fruit and Vegetables)

- 10 to 100 t/h

- Capacity (UHX HD for Fruit and Vegetables)

- 65 to 200 t/h

- Capacity (UHX R Turbo Extractor Refiner)

- 1 to 24 t/h

- Process Type

- Hot and Cold Extraction

- Process Type

- Hot Break / Cold Break

- Performance

- High efficiency and yield

- Hygiene and Maintenance

- Improved hygiene and easy maintenance

- Working mechanism

- Turbo extraction

- Integrated steps

- Hot and cold extraction

- Batch vs. continuous operation

- Continuous operation

- Cleaning method

- CIP (Clean-In-Place)

- Automation level

- High automation with PLC control

- Handling capabilities

- Fruit and vegetable processing

- Capacity range

- 1 to 200 t/h

- Turbine type

- Alveolar and hypocycloidal rotor

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Processing Type

- Hot extraction / Cold extraction

- Product Form

- Chopped / Heated / Destoned

- Final Use

- Baby Foods / Nectars / Packed Aseptically

- Machine footprint

- Compact design

- Feed/discharge method

- Hot and cold extraction

- Rotor type

- Alveolar and Hypocycloidal

- Model sizes

- 9 different sizes