Batch processing system for processed cheese and various food products

Optimize your food production line with a multifunctional batch processing system designed to efficiently blend, cook, and pasteurize a wide range of products while ensuring precise temperature control and enhanced product quality.

Blends, Cooks, and De-aerates Liquid and Slurry Products

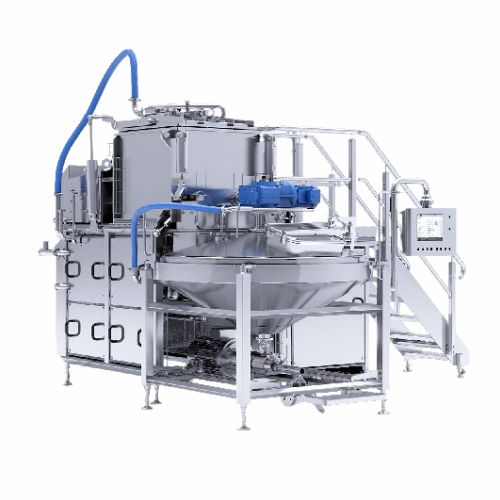

The FreeTherm 150 from Natec is a multifunctional batch processing system designed for diverse food industry applications, including the production of processed cheeses, sauces, purees, and specialized food items. This equipment stands out due to its unique direct steam injection and integrated vacuum system, which ensure even heating and product de-aeration, enhancing density control and color stability. Suitable for producing end-products like cheddar cheese slices, Alfredo sauce, and organic baby cereal, it processes up to 750 kg per hour, making it ideal for high-speed operations. Automation is facilitated through a PLC-controlled central surveillance system, allowing for seamless integration into existing production lines. Additionally, its CIP (Clean-In-Place) capability with automatic programs simplifies maintenance and ensures hygienic operation. Constructed with all product contact surfaces in 316L stainless steel, it offers durability and corrosion resistance, meeting industry standards for food safety. Customizable features such as powder and ingredient addition systems and various mixing auger configurations provide further flexibility to meet specific processing needs.

Benefits

- Enhances product quality through precise steam injection and de-aeration, ensuring consistent texture and flavor.

- Increases production efficiency with the ability to process up to 750 kg per hour.

- Minimizes maintenance downtime with CIP capabilities for quick, hygienic cleaning.

- Versatile processing supports a wide range of food products and viscosities.

- Streamlines operations with customizable configurations to meet specific processing requirements.

- Applications

- Meat products, Sauces, Pet food, Specialty food, Baby food, Fruits, Processed cheese, Vegetables, Purees, Pasta filata types

- End products

- Alfredo sauce, Cheddar cheese slices, Canned dog food, Diced carrots, Tomato puree, Vegan cheese spread, Marinated artichoke hearts, Ground meat patties, Mozzarella cheese sticks, Organic baby cereal

- Steps before

- Grinding, Blending, Feeding, Ingredient Addition

- Steps after

- Cooling, Insulated Buffer Storage, Packing, Distribution

- Input ingredients

- processed cheese ingredients, pasta filata ingredients, sauce ingredients, puree ingredients, baby food ingredients, meat ingredients, pet food ingredients

- Output ingredients

- processed cheese, pasta filata, sauces, purees, baby food, meat products, pet food

- Market info

- Hochland Natec is known for manufacturing innovative engineered-to-order equipment and solutions for the dairy and food processing industry, specializing in cheese production and processing technologies, with a strong reputation for quality and innovation.

- Batch size

- 150 kg (330 lbs)

- Capacity

- Up to 750 kg/h (1, 650 lbs/h)

- Heating temperature

- Up to 98 °C (208 °F)

- Dimension (LxWxH)

- 3, 650 x 3, 550 x 3, 150 mm

- Voltage

- 400 V, 50 Hz, 3 phase

- Heating method

- Direct steam injection

- Automation

- Central control and surveillance system

- Cleaning method

- Automatic cleaning via spray balls (CIP system)

- Material

- 316 L stainless steel for product contact surfaces

- Working mechanism

- Batch processing system

- Integrated steps

- Mixing, heating, de-aerating

- CIP/SIP

- Automatic CIP

- Batch vs. continuous operation

- Batch

- Automation level

- Central control surveillance system

- Air incorporation control

- Vacuum system for de-aeration

- Cleaning method

- Automated CIP

- Cleanability

- Clean-In-Place (CIP)

- Corrosive resistance (e.g. acids)

- 316 L stainless steel

- Viscosity range

- Low to high viscosity

- Heat sensitivity

- High-temperature durability

- Foaming tendency

- Minimal foaming

- Product consistency

- Emulsions, pastes, liquids

- Abrasion resistance

- Yes

- De-aeration capability

- Requires vacuum de-aeration

- Temperature range

- Up to 98°C (208°F)

- Batch size flexibility

- 150kg per batch

- Product composition variation

- Creams, purees, meat, cheese

- Color stability

- Requires controlled de-aeration

- Product load range

- Up to 750kg/h

- Machine footprint

- 3, 650 x 3, 550 x 3, 150 mm

- Feed method

- Bin lifter for ingredients addition

- Discharge method

- Discharged into an insulated buffer tank

- Material

- 316 L stainless steel

- Control panel type

- Central control and surveillance system

- Discharge method

- Insulated buffer tank with agitator

- Mixing auger executions

- Different options available depending on product requirement

- Cleaning integration

- Automatic cleaning via spray balls and integrated systems

- Additional functions

- Bin lifter, steam conditioning unit, powder and ingredient addition systems

- Execution options

- Double jacketing of processing vessel