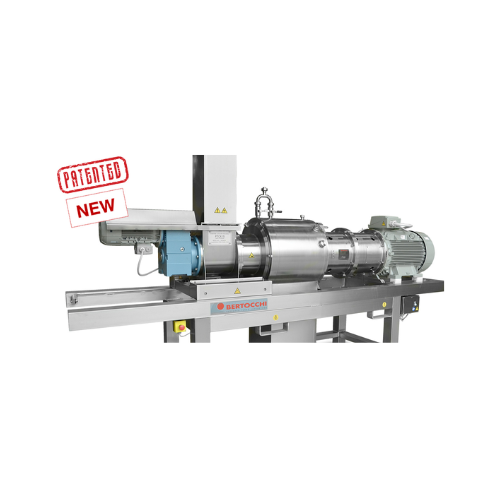

Industrial depitter for stone fruits

Effortlessly process stone fruits into smooth purees and nectars with a continuous, cold extraction system that ensures high yield and quality, eliminating the need for mechanical adjustments with size or ripeness changes.

Destones and Purees Fruits for Cold Extraction

The PTCX Turbo Depitter by Bertocchi Srl is a robust solution for processing peaches and apricots into premium purees and nectars. This equipment is designed for continuous operation, utilizing a cold extraction process that preserves the natural flavors and nutrients of the fruit. Capable of handling up to 15 tons per hour, the PTCX ensures efficient destoning with its integrated Rotopulse® softening section, effectively preparing fruit without mechanical adjustments for varying fruit sizes and conditions. This minimizes downtime and reduces maintenance, making it ideal for juice manufacturers and puree production facilities.

Operating as both a depitter and a puree processor, the machine seamlessly integrates into pre-processing and processing lines, ideal for baby food and juice production. It excels in energy efficiency by eliminating the need for traditional drum-style destoners, and its continuous operation boosts productivity. Constructed from high-grade materials suited for the food industry, the PTCX maintains hygienic standards and is easy to clean, supporting safe and efficient industrial applications.

Benefits

- Maximizes production efficiency with continuous destoning and pureeing processes.

- Reduces maintenance time through automatic adaptation to fruit size and ripeness.

- Preserves natural fruit qualities with cold extraction, ideal for premium purees and nectars.

- Optimizes line integration, eliminating the need for separate destoners.

- Increases product quality with clean stone removal, enhancing puree yield.

- Applications

- Baby food, Fruit purees, Fruit nectars

- End products

- Avocado baby food puree, Puree for fruit beverage blends, Peach baby food puree, Cold-extracted peach nectar, Mango baby food puree, Cold-extracted apricot nectar, Cold-extracted plum nectar, Apricot baby food puree, Cold-extracted cherry nectar

- Steps before

- Fruit Sorting, Fruit Washing, Fruit Inspection

- Steps after

- Purée Sterilization, Purée Aseptic Packaging, Purée Hot Packing

- Input ingredients

- peaches with stone, apricots with stone, peaches and apricots at room temperature (with stone)

- Output ingredients

- fruit puree, purée to be packed at hot temperature, aseptic, baby foods, nectars

- Market info

- Bertocchi is known for manufacturing engineered-to-order industrial equipment, specializing in custom process solutions for the food and beverage industry. They have a strong reputation for innovation, quality, and reliability in producing machinery tailored to customer specifications.

- Capacity

- 5–15 t/h

- Processing temperature

- Room temperature

- Process type

- Continuous process

- Automation

- Continuous working

- Maintenance requirement

- Low maintenance

- Working mechanism

- Continuous process

- Integrated steps

- Destoning and puree extraction

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- Manual / PLC

- Cleaning method

- Low maintenance

- Changeover time

- Minimal, due to no mechanical adjustment needed

- CIP/SIP

- Not specified

- Energy efficiency

- Not specified

- Yield and quality optimization

- High yield, whole stone removal

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Fruit type

- Peach / Apricot / Plum / Cherry / Mango / Avocado

- Final product type

- Fruit pureé

- Feed method

- Manual / Automatic

- Shape

- Rotary / Drum

- Size

- Max capacity from 5 to 15 t/h

- Rotopulse® softening section

- Integrated

- Continuous working mechanism

- Yes

- Control panel type

- Integrated system

- Integration possibilities

- Forefront System integration

- Compact footprint

- Yes

- Discharge method

- Continuous