Automated sauce production lines

Streamline your sauce production with flexible lines designed for rapid recipe changeovers, ensuring consistent quality and enhanced efficiency from cooking through to packaging.

Processes and Packages Sauces with Precision

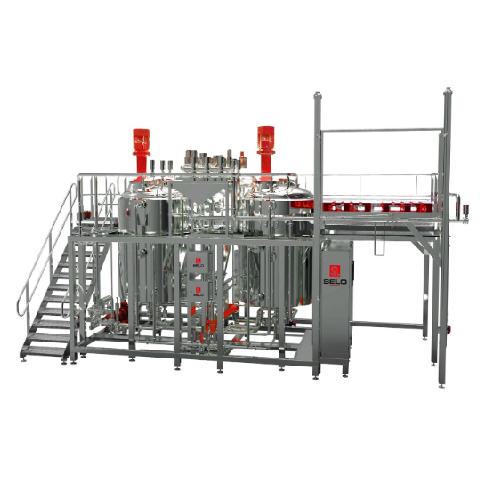

The Selo Sauce Production and Packaging System offers a robust solution for food processing companies seeking to enhance their production capabilities. This system specializes in cooking, pasteurizing, chilling, and homogenizing a variety of sauces and liquid food products, ensuring seamless recipe changeovers and integration with packaging lines. Designed with high hygiene and quality standards, it efficiently produces end-products such as pasta sauces, soups, and dressings. Operating within food, sauce, and baby food production industries, this fully automatic system supports continuous high-speed operations. Selo’s equipment can be tailored to suit specific production requirements, offering features like direct steam injection, pressure/vacuum cooling, and homogenizers. The system is constructed from high-quality materials to guarantee compliance with food safety standards, while its CIP system facilitates swift cleaning and maintenance. With engineering support for customization, Selo ensures that your equipment aligns perfectly with your operational needs, ultimately optimizing efficiency and throughput.

Benefits

- Enhances production efficiency by enabling fast and precise recipe changeovers, minimizing downtime.

- Integrates seamlessly with existing packaging systems, ensuring smooth workflow and consistent output.

- Reduces waste and increases yield with precise portion control and immediate discrepancy detection.

- Ensures compliance with the highest hygiene and food safety standards, protecting product integrity.

- Customizable design allows adaptation to specific production needs, optimizing process efficiency.

- Applications

- Soups, Sauces, Meat sauces, Spaghetti sauce, Vegetable sauces, Pasta sauce, Dressings, Liquid food products, Baby food, Pizza sauce

- End products

- Mushroom cream sauce, Vegetable beef soup, Curry sauce, Bbq sauce, Hummus, Caesar dressing, Alfredo sauce, Marinade, Cheese sauce, Hot sauce, Bolognese sauce, Vinaigrette dressing, Marinara sauce, Chicken noodle soup, Tomato basil pasta sauce, Sweet and sour sauce, Apple baby puree, Ranch dressing, Tomato ketchup

- Steps before

- Pre Engineering, Project Management, Engineering

- Steps after

- Packing, Installation, Commissioning, Aftersales, Sterilization, Packing

- Input ingredients

- raw ingredients, spices, vegetables, meat, pasteurized materials

- Output ingredients

- pizza sauce, pasta sauce, spaghetti sauce, meat sauces, vegetable sauces, soups, dressings

- Market info

- Selo is known for providing industrial engineered-to-order equipment solutions, specializing in processing and packaging systems. They are reputed for their innovative engineering, customization capabilities, and a strong commitment to quality and customer satisfaction within various industries.

- Accuracy

- High portion accuracy

- Automation

- Fully Automatic Process

- Capacity

- High production levels

- Direct Steam Injection

- Optional

- Pressure/Vacuum Cooling

- Optional

- Energy Efficiency

- Improved profitability

- Homogenizer

- Optional

- Recipe Changeover

- Fast and Effective

- Safety Standards

- Strict Hygiene, Safety

- Seamless Integration

- With Packaging Lines

- Portion Control

- High precision, speed

- Working mechanism

- Fully automatic

- Integrated steps

- Production, pasteurization, chilling

- Automation level

- PLC / SCADA

- Recipe changeover time

- Fast and effective

- Batch vs. continuous operation

- Batch / Inline Continuous

- Seamless integration

- Packaging process

- Energy efficiency

- High

- CIP/SIP

- CIP

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Foaming sensitivity

- High / Low

- Container type

- Stand-up pouches / Jars / Bottles

- Tank shape

- Cylindrical/Rectangular

- Tank size

- 500 L – 5000 L

- Feed/discharge method

- Direct steam injection/Pressure/vacuum cooling

- Control panel type

- PLC/Touchscreen

- Control panel type

- HMI / Touchscreen

- Integration possibilities

- SCADA / ERP integration

- Direct steam injection

- Optional

- Pressure/vacuum cooling

- Optional

- Homogenizer integration

- Optional