High-efficiency high-capacity reactor for industrial processing

Enhance production efficiency with a reactor system designed for high-volume processing, ensuring optimal heat transfer and minimized processing time. Ideal for tackling demanding applications involving products of varying viscosities and particle sizes.

Processes and Mixes Viscous and Particulate Products

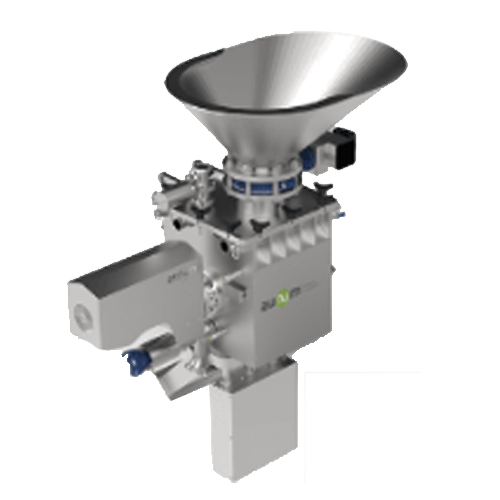

The T-Sensation high-efficiency reactor from Aurum Process Technology offers a cutting-edge solution for diverse industrial applications. Featuring a horizontal stainless steel design, it processes volumes from 50 to over 1000 liters, utilizing scraping systems to enhance heat transfer and mixing. Its efficiency stems from the internal plates that maximize heat transfer surfaces, reducing processing time and energy consumption. Ideal for applications ranging from broths and fruit pulps to shampoos and creams, it supports food, beverage, personal care, and infant food industries. The reactor operates under both pressurized and vacuum conditions, excelling in processes including heating, evaporation, and crystallization. Designed to maintain product integrity and minimize fouling, the T-Sensation is suitable for both batch and continuous operations, facilitating aseptic processing without pump feeding. Its compliance with high-quality product standards ensures low shearing and maintains nutritional properties, making it an asset in any production line seeking efficiency and flexibility.

Benefits

- Enhances processing efficiency with reduced energy consumption through optimized heat transfer.

- Maintains product quality by preserving nutritional and flavor integrity with minimal shearing.

- Supports versatile operations by handling variable viscosities in both batch and continuous modes.

- Facilitates installation in existing lines with seamless integration for pressurized and vacuum conditions.

- Minimizes product loss during cleaning and transition cycles, ensuring operational cost-efficiency.

- Applications

- Sauces, Industrial vegetable processing, Products of any degree of viscosity, Broths, Convenience food, Vegetable creams, Products with particles of variable sizes, Body care, Industrial fruit processing, Infant food

- End products

- Baby food purees, Vegetable broth, Carrot cream, Fruit pulps, Pumpkin soup, Chicken broth, Pasta sauces, Mashed potatoes, Salad dressings, Ready-to-eat meals, Shampoo base, Cream lotions, Tomato paste, Applesauce, Fruit concentrates

- Steps before

- Purification, Hydrating, Blending, Formulating

- Steps after

- Sterilization, Packaging, Cooling, Concentration

- Input ingredients

- broths, industrial fruit, body care ingredients, convenience food ingredients, sauces, vegetable creams, infant food, industrial vegetables, products with variable sizes, products of any viscosity, dry products

- Output ingredients

- high-quality product, flavourful product, nutritious product, products with maintained integrity

- Market info

- Aurum specializes in the design and manufacture of custom-engineered industrial equipment, known for their innovative solutions, high-quality craftsmanship, and reliable performance in complex projects, establishing a strong reputation in the ETO equipment market.

- Performance

- Tenfold over conventional reactors

- Capacity

- 50 to over 1000 litres

- Material

- Stainless steel

- Heating surface

- Scraped surface

- Process type

- Batch or continuous

- Pressure capability

- Pressurised and vacuum conditions

- Working Mechanism

- Horizontal reactor with scraping system

- Batch vs. continuous operation

- Batch / Continuous

- Vacuum Processing

- Available

- Pressurised processing

- Available

- Integrated Steps

- Evaporation, heating, cooling

- Energy Efficiency

- High

- Cleaning Method

- CIP / SIP

- Aseptic Processing

- Direct Cooling

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- Any degree of viscosity

- Particle size variability

- Variable sizes

- Reactor shape

- Horizontal

- Material

- Stainless Steel

- Capacity

- 50 to 1000+ Liters

- Heat transfer surface

- Scraped surface

- Scraping system

- Optimized for mixing

- Loading method

- Worm screw / Chain or belt-type bucket elevators

- Pressure conditions

- Pressurized and vacuum

- Material of construction

- Stainless steel

- Scraping system

- Fully scraped surface

- Volume capacity

- 50 to over 1000 litres

- Operation mode

- Batch or continuous