Batch processing system for processed cheese and sauces

Optimize your food processing line with a versatile batch processing system designed for efficient blending, cooking, and de-aerating of diverse products like processed cheese, sauces, and purees, ensuring high-quality results with every batch.

Blends, Cooks, and Pasteurizes Diverse Food Products

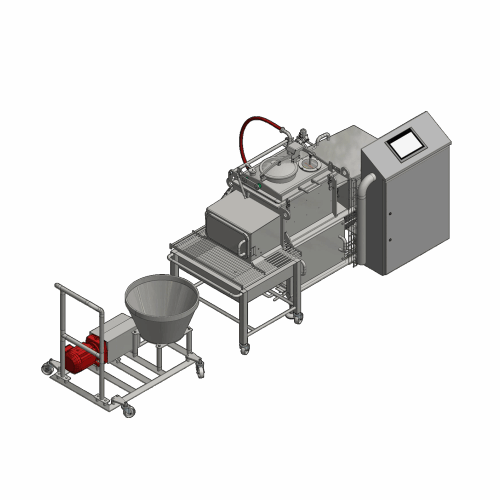

The FreeTherm 50 from the Natec Network is a multifunctional steam batch cooker engineered for food processing companies requiring precise control over blending, cooking, and pasteurizing a wide array of products. This system utilizes direct steam injection and integrated vacuum technology for efficient heating and de-aeration, ensuring uniform temperature distribution and superior product quality without hotspots. Ideal for producing processed cheese, sauces, and baby foods, the FreeTherm 50 can process batches up to 50 kg and achieve a throughput of up to 250 kg per hour. Its design includes a fully enclosed CIP cleaning system, 316L stainless steel contact surfaces for hygiene and durability, and optional central control for seamless integration into existing production lines. With customizable features such as different mixing augers and ingredient systems, it offers scalability and flexibility for diverse food industries, providing a robust solution for developing innovative and high-quality end products.

Benefits

- Enhances production flexibility with multifunctional batch processing.

- Improves product quality with precise temperature control and de-aeration.

- Streamlines cleaning and maintenance with a built-in CIP system.

- Reduces energy use with efficient direct steam injection.

- Customizable to meet diverse production requirements and increase efficiency.

- Applications

- Sauces, Soups, Pasta filata, Pet food, Specialty food, Meat, Baby food, Processed cheese, Dressings, Vegetables, Purees, Fruit

- End products

- Alfredo sauce, Caesar dressing, Cheddar cheese slices, Tomato soup, Mozzarella sticks, Rice cereal baby food, Fruit compote, Vegetable puree, Plant-based cheese, Ground beef filling, Rice dog food, Pumpkin puree, Beef

- Steps before

- Ingredient addition, Grinding, Blending

- Steps after

- Discharge to R, D trolley, Packaging, Cooling

- Input ingredients

- processed cheese, pasta filata types, sauces, purees, baby food, meat, pet food

- Output ingredients

- processed cheese, pasta filata, soups, sauces, dressings, meat products, fruit, vegetables, baby food, specialty food, pet food

- Market info

- Hochland Natec is known for manufacturing innovative engineered-to-order equipment and solutions for the dairy and food processing industry, specializing in cheese production and processing technologies, with a strong reputation for quality and innovation.

- Batch size

- 50 kg (110 lbs)

- Capacity

- Up to 250 kg/h (550 lbs/h)

- Dimensions

- LxWxH

- Voltage

- 400 V, 50 Hz, 3 phase

- Heating temperature

- Up to 98 °C (208 °F)

- Material

- 316 L stainless steel

- Automation

- Central control and surveillance system

- Cleaning method

- Optional CIP ability

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Batch

- CIP/SIP

- CIP

- Cleaning method

- CIP

- Heating method

- Direct steam injection

- Vacuum system

- Integrated

- Blending efficiency

- Mixing pattern flexibility

- Operator comfort

- Central control surveillance system

- Changeover time

- Not specified

- Energy efficiency

- Not specified

- Cleanability

- Fully enclosed, CIP able

- Corrosive resistance (e.g. acids)

- 316 L stainless steel

- Biological compatibility

- Hygienic design ensuring product safety

- Abrasion resistance

- Suitable for abrasive materials

- Foaming tendency

- Low viscosity products

- Heat sensitivity

- Temperature controlled up to 98 °C

- Viscosity range

- Low to high viscosity

- Container size compatibility

- 50 kg per batch

- Product homogenization

- Two independently controlled augers

- Material de-aeration

- Integrated vacuum system

- Machine footprint

- 2, 400 x 1, 200 x 1, 550 mm

- Batch size

- 50 kg per batch (110 lbs)

- Batch frequency

- Up to 5 batches per hour

- Construction material

- 316 L stainless steel

- Discharge method

- Discharged into an R, D trolley or insulated buffer tank

- Heating temperature

- Up to 98 °C (208 °F) by direct steam injection

- Control panel type

- Central control and surveillance system

- Discharge method

- Combined discharge and CIP pump

- Additional functions

- Options for lifting equipment, steam conditioning unit, and powder addition systems

- Mixing auger executions

- Different executions available depending on product requirement

- Shaft seal upgrade

- Available

- Integration

- Optional CIP ability and connection to existing systems