Iceberg lettuce decoring and cutting system

Optimize your salad production with precise decoring and cutting, ensuring maximum yield and consistent quality in iceberg lettuce processing.

Decores and Cuts Iceberg Lettuce Efficiently

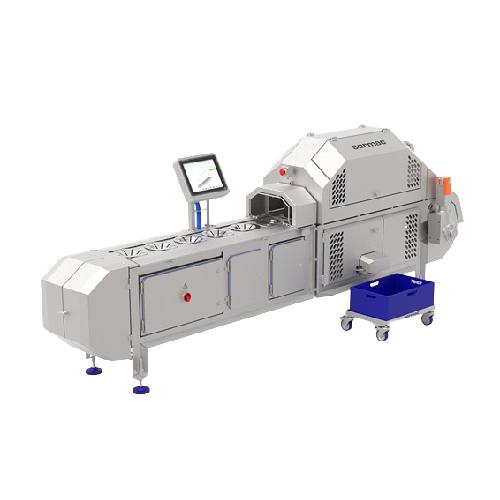

The OptiCor OC-60 from Sormac is an innovative solution designed for the precise decoring and cutting of iceberg lettuce. This system utilizes a unique combination of manual and automated processes, enabling high-speed operations essential for modern food processing and salad production facilities. The machine’s working principle involves a stepflow singulator for automatic filling, with pockets that move using a start-stop mechanism. A camera-based alignment system ensures precise core positioning and depth calculation, optimizing yield by decoring from underneath to separate the core efficiently.

The OptiCor OC-60 is ideal for preparing a variety of salad mixes and pre-cut lettuce, accommodating heads with diameters between 90 and 220 mm. With a maximum throughput of 60 pieces per minute, it supports both continuous and high-speed operations, adjustable based on operator skill level. Optional features include segmenting the lettuce into 2, 4, or 8 pieces post-decoring and integrating with conveyors for seamless production line integration.

The machine’s energy efficiency is bolstered by its precision alignment system, reducing waste and enhancing productivity. Constructed for durability and ease of maintenance, the OptiCor OC-60 integrates smoothly into existing lines, often combined with complementary Sormac equipment like flume conveyors and salad washers for comprehensive processing solutions.

Benefits

- Increases yield by optimizing decoring depth and core separation.

- Enhances processing efficiency with a throughput of up to 60 pieces per minute.

- Reduces manual intervention with automated alignment and cutting options.

- Integrates seamlessly into existing processing lines with optional conveyor systems.

- Minimizes waste and improves product quality with precise cutting and segmenting capabilities.

- Applications

- Salad preparation, Iceberg lettuce processing

- End products

- Pre-cut iceberg lettuce, Iceberg lettuce cores, Packaged salad mixes

- Steps before

- Washing, Singulating, Aligning

- Steps after

- Cutting, Conveying, Drying, Packaging

- Input ingredients

- iceberg lettuce, lettuce heads

- Output ingredients

- decorated lettuce, segmented lettuce, lettuce cores

- Market info

- Sormac is known for its expertise in manufacturing high-quality vegetable processing equipment, particularly peeling, washing, and slicing machines, with a strong reputation for innovation, reliability, and customer-focused solutions in the food processing industry.

- Capacity

- 60 pieces per minute

- Decoring diameter range

- 90–220 mm

- Automation

- Stepflow singulator / camera alignment

- Cutting options

- 2, 4, or 8 pieces

- Working Mechanism

- Start-stop principle

- Automation Level

- Manual / Automated with optional stepflow singulator

- Integrative Technology

- Camera-based alignment system

- Cutting Options

- 2, 4, or 8 pieces after decoring

- Operation Speed

- 60 pieces per minute

- Operation Speed (Segmented)

- 45 pieces per minute

- Yield Optimization

- Optimal decoring depth control

- Feed method

- Manual/Automatic with stepflow singulator

- Discharge method

- Outfeed conveyor

- Product size compatibility

- Iceberg lettuce diameter 90–220 mm

- Conical decoring knives

- Adjustable

- Pocket alignment system

- Camera-based

- Filling method

- Manual/Automatic with stepflow singulator

- Cutting configuration

- 2, 4, or 8 pieces

- Decoring depth adjustment

- Automatic based on camera measurements

- Outfeed system

- Outfeed conveyor