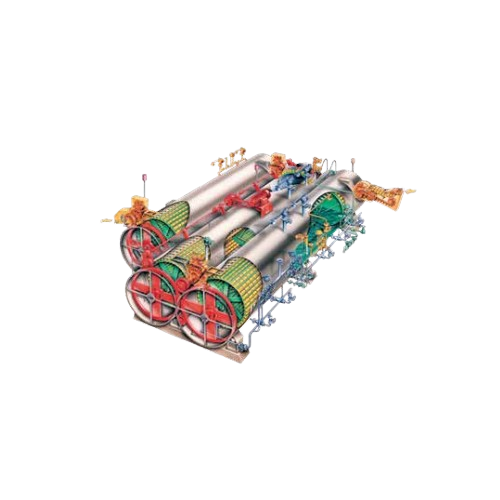

Gentle can handling ejector for rotary cooker

Achieve seamless can transfer and sterilization with reduced damage during high-speed operations, ensuring integrity for products ranging from delicate baby foods to robust pet meals.

Transfers and Ejects Cans Gently

The Gentle Can Handling Ejector from JBT FoodTech’s Rotary Pressure Sterilizers is engineered to minimize can damage during high-speed operations. It facilitates a controlled tangential path for metal cans, ensuring a smooth transition from shell to shell, crucial for sensitive products like infant formula and yogurt alternatives. This equipment supports continuous processing, enabling increased throughput for applications such as ready meals and sauces. Its design allows for integration into both new and existing sterilization setups, featuring configurable transfer components to reduce setup time and transfer jams. The system is compatible with lightweight and necked-in cans, offering energy efficiency and reduced operational costs due to its optimized motion control. Available in corrosion-resistant materials, it meets stringent industry standards, making it a reliable component for food and pet food manufacturers.

Benefits

- Minimizes can damage, reducing product loss and maintaining packaging integrity.

- Supports high-speed production lines, enhancing manufacturing efficiency and output.

- Enables the use of lighter and necked-in cans, lowering material costs.

- Reduces transfer jams, ensuring smoother operations and less downtime.

- Retrofit capability allows seamless integration into existing systems, optimizing investment costs.

- Applications

- Soups, Sauces, Ready meals, Pet food, Dairy alternatives, Oils, Dressings, Seasonings, Baby food, Dairy

- End products

- Tomato soup, Infant formula, Barbecue sauce, Microwavable lasagna, Salad dressings, Baby vegetable puree, Vinaigrettes, Instant pasta meals, Curry-based ready-to-eat meals, Cat food, Meat-based gravy, Plant-based milk, Yogurt alternatives, Canned dog food

- Steps before

- Filling, Seaming, Preparation

- Steps after

- Cooling, Labeling, Packaging

- Input ingredients

- metal cans, lighter weight cans, necked-in cans, body chime cans

- Output ingredients

- processed cans, sterilized cans, ejected cans

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Can Handling

- Gentle Ejector Technology

- Can Size Compatibility

- Lighter Weight, Necked-in

- Automation

- PLC Automated Control

- Throughput

- Increased for High-Speed Lines

- Adaptability

- New, Retrofit Applications

- Can transfer mechanism

- Tangential path

- Reduced can damage

- Minimized sharp impacts

- Compatibility

- New and existing RPS equipment

- Operation type

- Retrofit kit or new units

- Throughput increase

- Faster equipment speeds

- Automation level

- Manual / PLC / SCADA

- Smooth can transfer

- More forgiving setup

- Jam frequency

- Reduced

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat sensitivity

- Reduced can damage

- Footprint

- Compact

- Discharge method

- Tangential path

- Control panel type

- PLC

- Transfer path

- Tangential

- Can size compatibility

- Lighter weight, necked-in cans

- Retrofitting

- Available for existing RPS units

- Control Panel Type

- NA