Aseptic Filling Equipment

Connect directly with world-leading production technology suppliers of innovative aseptic filling equipment

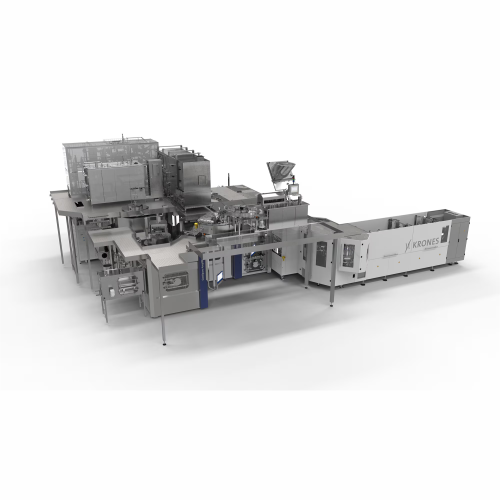

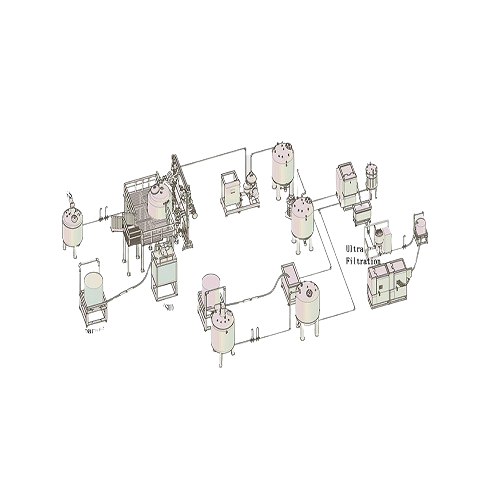

Aseptic filling equipment is crucial for sensitive products, as they need to be filled into their primary packaging in an environment free from contamination caused by harmful bacteria, viruses, or other microorganisms. Choosing an aseptic filling solution requires consideration of the physical form of the product, the type of primary packaging, the volume to be dosed per package, and the production speed. Aseptic fillers are widely used for cleaning, filling, and sealing pre-sterilized vials, cartridges, ampoules, and syringes in the pharmaceutical industry. Aseptic filling is also used in the food industry to process for example, dairy products that need harmful bacteria's minimized, or ensure shelf-stable products that do not require refrigeration. In these industries, aseptic equipment is integrated into the production line for maximum isolation and sterilization. And, can either be configured as an automated or manual process, depending on standards that the products require.

What are you making?

Active pharmaceutical ingredients (API)

Ampoules

Baby Food

Chocolate fillings

Chocolate milk

Condensed milk

Cough syrup

Eardrops

Eyedrops

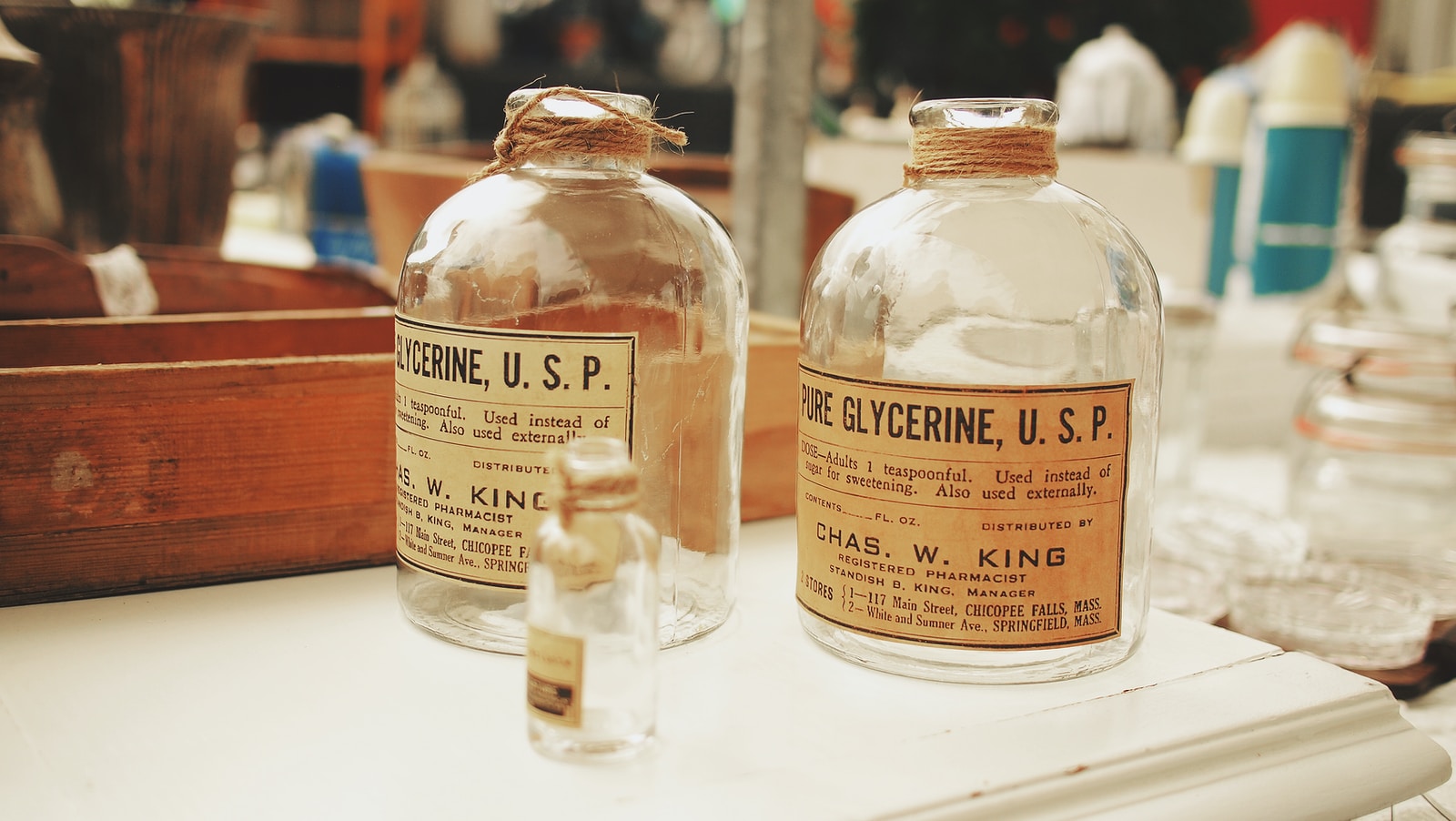

Glycerine

Ground coffee

HPMC capsules

Insulin

Mayonnaise

Mineral water

Nasal spray

Ointment

Oleochemicals

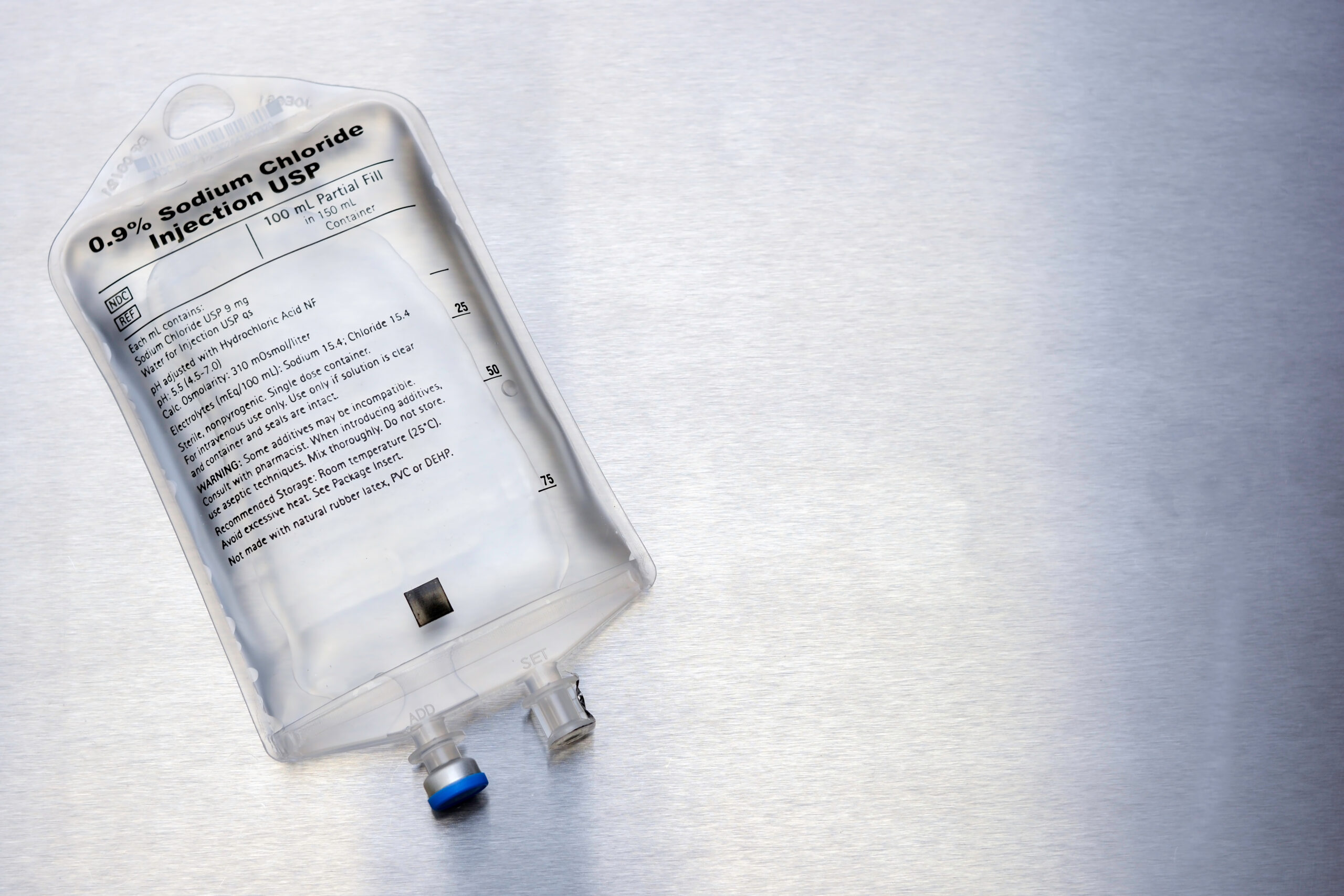

Parenterals

Pharmaceutical cartridges

Pre-filled Syringes

Single-use bags

Vaccines

Vials

Water for injection

Which aseptic filling equipment technology do you need?

Aseptic separator for high solid content in biopharma

Ensure high yield and optimal purity in biopharmaceuticals with thi...

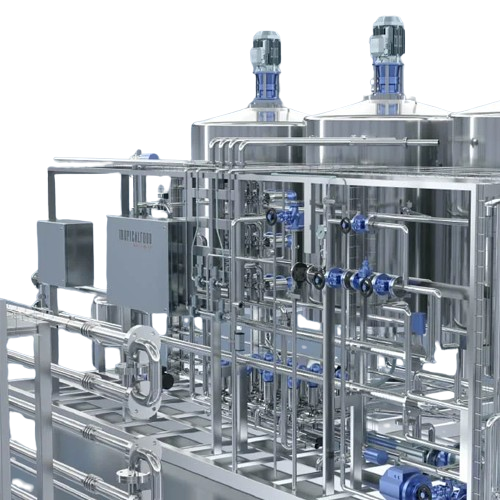

Aseptic tank for sterile liquid food storage

Ensure sterility and maximize shelf life for liquid foods by utilizing an ase...

Aseptic thermal processor for high viscosity products

Optimize your processing of high viscosity products with precise te...

Uht/htst aseptic processor for pilot plants

Achieve precise heat treatment and aseptic processing with flexible pilot syst...

Cold aseptic filling solution for Uht samples

Ensure aseptic integrity and extend shelf life by securely filling and closi...

Aseptic filler for nutraceuticals

Ensure the sterility of your liquid nutraceuticals and beverages with a versatile solutio...

Aseptic bag-in-box filler for laboratory use

Achieve aseptic filling precision on a lab-scale with a compact solution that...

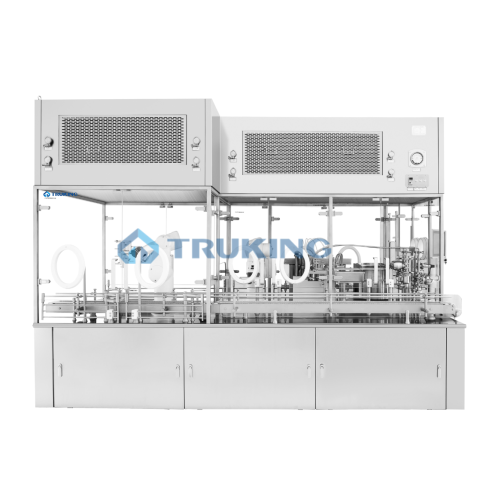

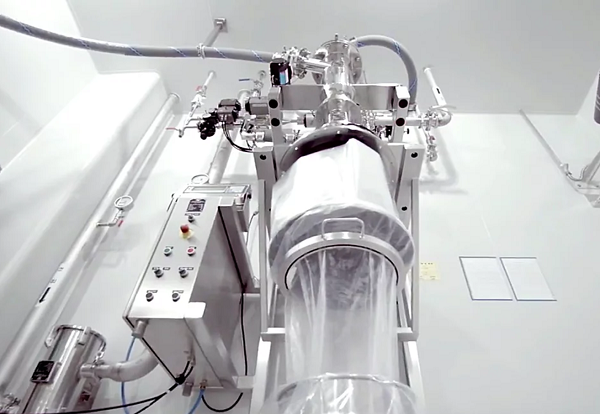

Aseptic filling system for biopharmaceutical products

This system ensures sterility in high-volume aseptic filling operat...

Aseptic ampoule filling and sealing solution

Ensure precise dosing and secure sealing of sterile liquid pharmaceuticals in...

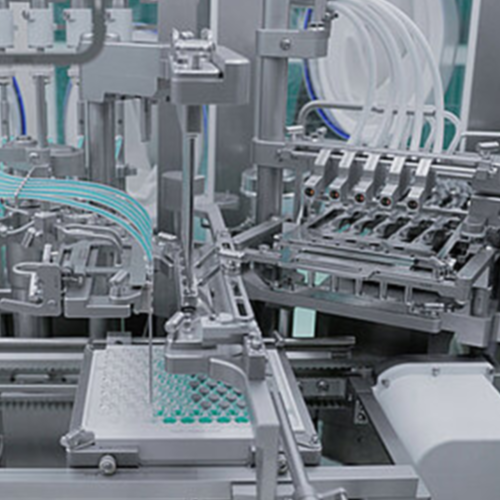

Aseptic vials filling and capping

Ensure precise vial capping and sealing for liquid pharmaceuticals with advanced aseptic ...

Aseptic filling and capping for vials and syringes

Ensure sterility and precision in vial and syringe filling with advanc...

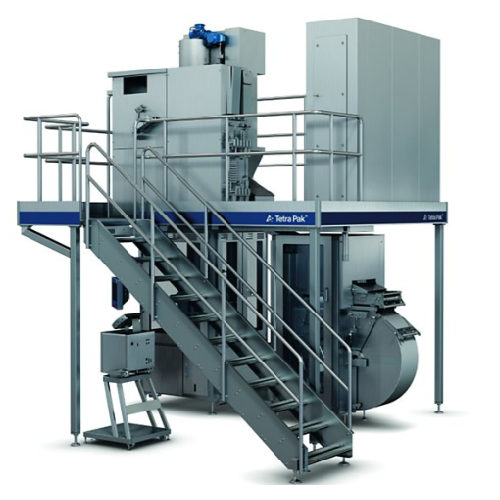

Ultrahygienic block for aseptic filling

When handling sensitive beverages, ensuring microbiological safety and quick produc...

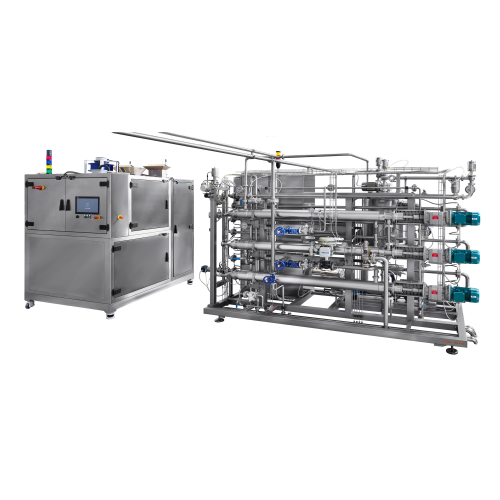

Uht system for aseptic filling of beverages

Ensure microbiological safety and retain natural flavors in your liquid produc...

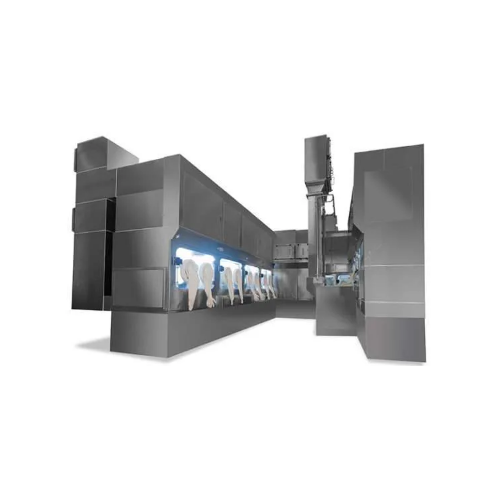

Aseptic bottle sterilisation system for Pet containers

Ensure aseptic integrity and high-speed efficiency in beverage pro...

Aseptic filling system for Pet containers

Ensure your beverage products maintain sterility and longevity with a high-speed...

Aseptic linear filler for sensitive beverages

Experience unparalleled versatility and efficient aseptic filling with advan...

Cold aseptic filling system for beverages

Ensure microbiological safety and high product quality with a versatile cold ase...

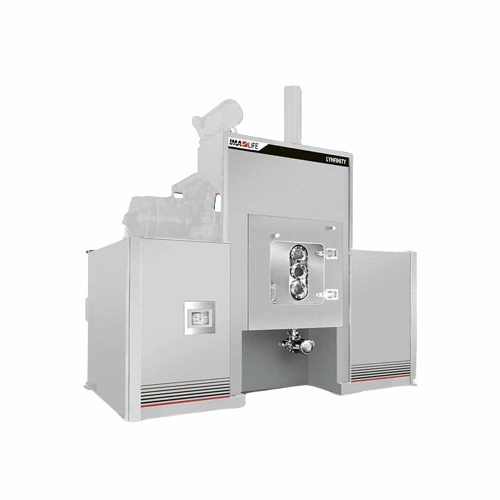

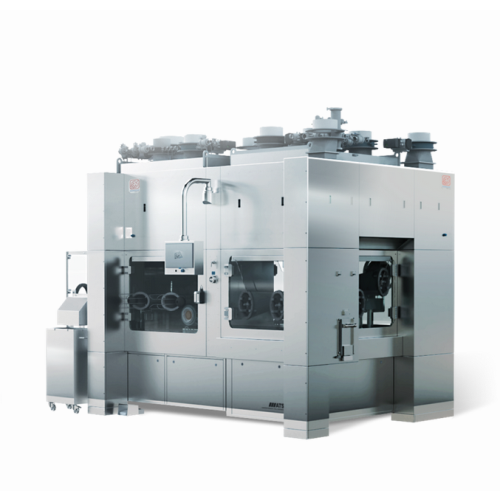

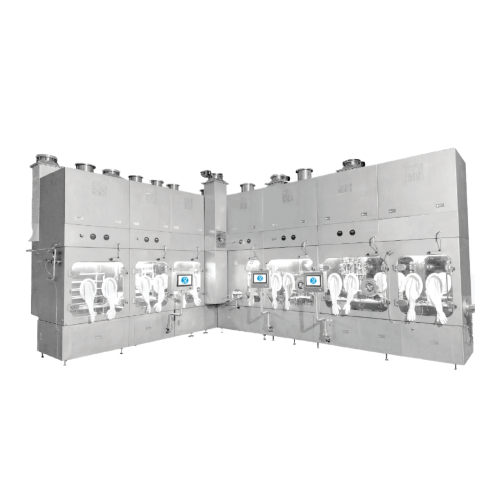

Isolation solutions for aseptic fill-finish lines

Achieve maximum product sterility with advanced isolation solutions, mi...

Continuous aseptic spray-freeze-drying system

Achieve higher sterility and improved product uniformity with a continuous a...

Aseptic filling and stoppering solution for vials

Ensure precise aseptic filling and stoppering of vials with enhanced fl...

Integrated vial filling system for aseptic and toxic pharmaceuticals

Minimize product loss and ensure high sterility in...

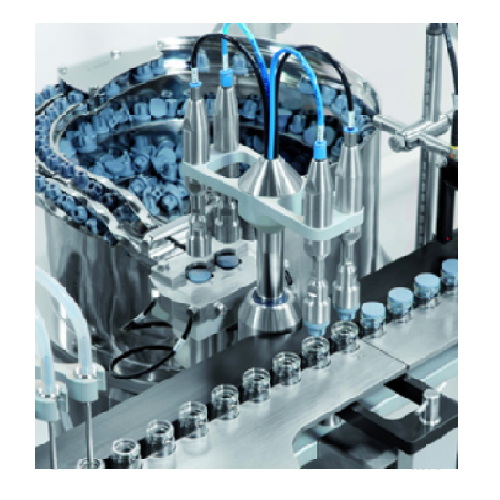

Aseptic filling solutions for Rtu vials, cartridges, and syringes

Optimize your aseptic filling processes with a system...

Aseptic syringe filling solution for Rtu containers

Streamline your pharmaceutical liquid filling operations with precise...

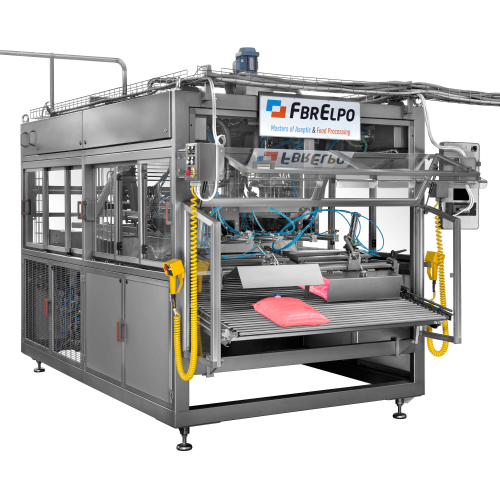

Industrial aseptic fillers for food processing

Ensure sterile packaging with advanced aseptic fillers, designed for precis...

Aseptic sterilizer for fruit-based products

Ensure product safety and extend shelf life with advanced sterilization techno...

Aseptic sterilizers for tomato products

Ensure your tomato-based and fruit products remain safe and shelf-stable with advan...

Aseptic filler for bag-in-box packaging

Achieve unparalleled product safety and quality in liquid packaging with our advanc...

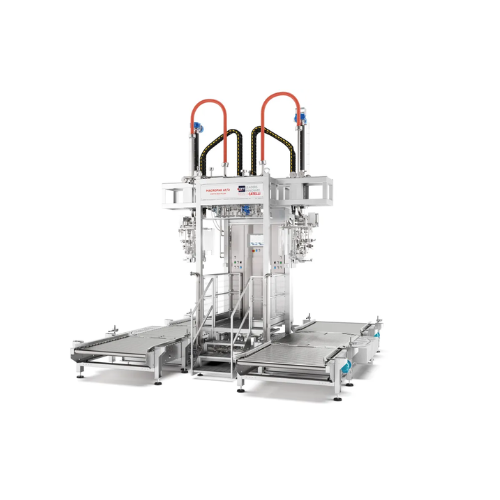

Aseptic filler for large bags

Ensure safe and sterile packaging of liquid and slurry products in large formats with this ase...

Aseptic filling system for bag-in-box packaging

Efficiently fill a range of liquid products into pre-sterilized bags while...

Aseptic filler for liquid and particulate products

Achieve precise, sterile filling of both liquid and chunky products wi...

Aseptic treatment and filling for concentrates and purees

Optimize your processing line with a compact solution that com...

Aseptic filler for bag in box packaging

Optimize your bag-in-box packaging process with high-speed aseptic filling, ensurin...

Aseptic bag-in-box filler for juices and purees

Enhance your filling operations with a high-speed aseptic solution designe...

High-throughput aseptic isolator for syringes and vials filling

Streamline your aseptic filling process with a high-spee...

Aseptic filling line for 131i sodium Iodide

Ensure compliant production of iodine-131 radiopharmaceutical vials with preci...

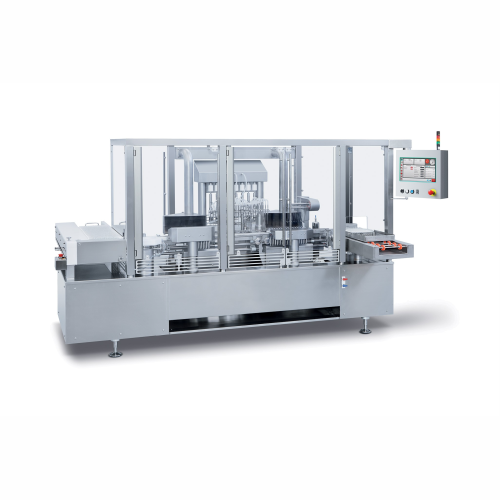

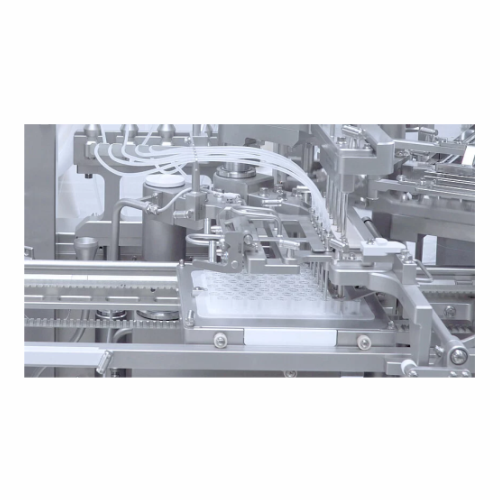

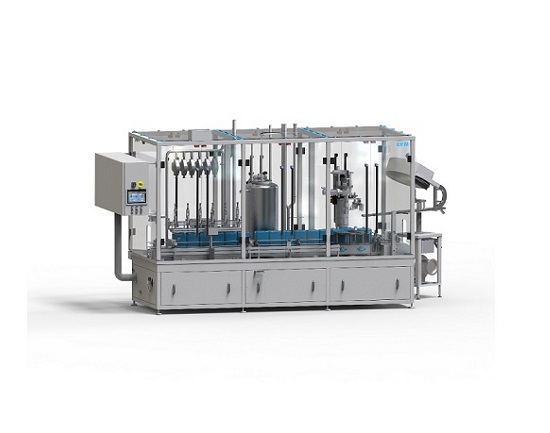

Automatic aseptic filling line for Iv bags

Ensure aseptic integrity and high-speed processing of IV bags with a filling li...

Compact aseptic vial filling system

Optimize your aseptic liquid filling with a compact system designed for seamless integr...

Aseptic fillers for liquid and viscous products

Ensure sterile and precise filling of liquid and viscous foods with adapta...

Semi-automatic aseptic filler for single bags

Ensure aseptic integrity and flexibility for your liquid and semi-liquid pro...

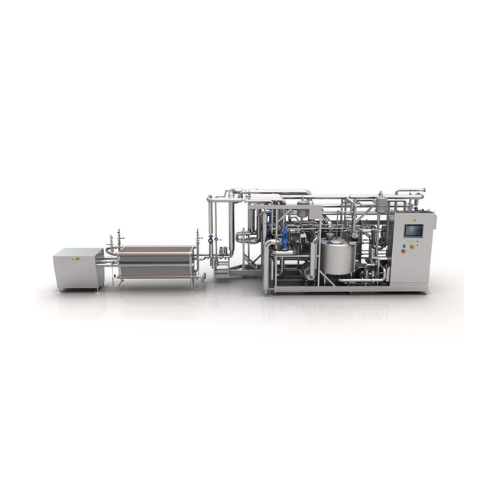

Aseptic filtration system for juice production

Ensure the microbiological quality and turbidity of juices and concentrates...

Aseptic filling system for fruit juices and nectars

Effortlessly integrate aseptic filling into your beverage production ...

Aseptic filling and closing for flexible Iv bags

Streamline your production line with high-speed aseptic filling and seali...

Aseptic cooking line for plant-based products

Enhance your production efficiency and product quality with an advanced doub...

Aseptic filler for bag in drum or box

Enhance product shelf life and maintain quality without preservatives by employing as...

Aseptic linear doypack filler

Ensure extended shelf life and preserve quality in liquid food products with this high-speed a...

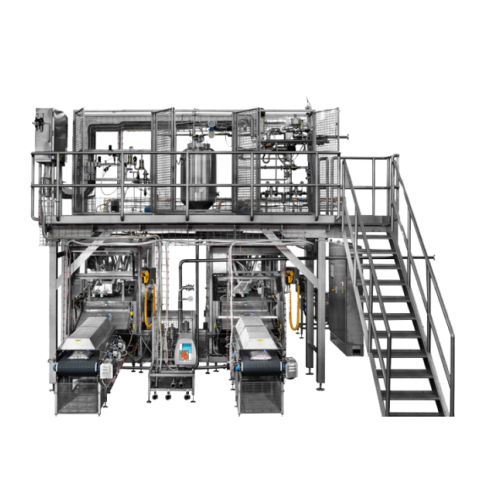

Aseptic cooking and filling line with two reactors

Streamline your production with a versatile line that combines high-ef...

Robotic filler for aseptic pharmaceutical packaging

Effortlessly manage complex aseptic filling tasks with a system desig...

Automated aseptic filling and closing system for vials and syringes

Optimize small-batch production with precision fill...

Aseptic small batch filling and closing system

Optimize your small-batch aseptic processing with this versatile system, de...

Aseptic liquid transfer connection system

Ensure sterile liquid transfer between containment areas with minimal product lo...

Aseptic vial filling system for gene therapy products

Elevate the sterility of your fill-and-finish process with a high-s...

Aseptic filling line for biopharmaceuticals

Streamline your aseptic filling process with precision dosing and minimal spac...

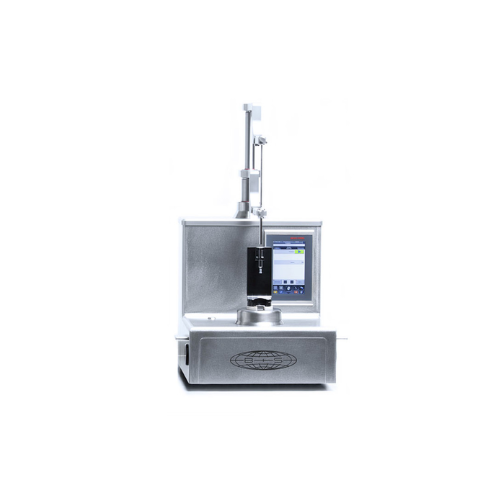

Aseptic filling station for small batch processes

Streamline small batch manufacturing with a tabletop filling station th...

Aseptic filling isolator for small cgmp batches

Guarantee aseptic integrity for small-scale batches with this isolator, of...

Aseptic filling solution for small cgmp batches

Ensure sterile and efficient filling of small-volume parenterals while mai...

Aseptic small / medium batch filling and closing system

Ensure sterility in drug production by seamlessly integrating a v...

Aseptic tank module for liquid food storage

Ensure safe storage of sterilized liquid foods with a customizable tank module...

Thousand-litre aseptic filler

Ensure the aseptic filling of bulk liquid and viscous food products, reducing contamination ri...

Aseptic processing equipment for food products

Optimize aseptic processing to ensure microbiological stability and product...

Aseptic processing system for food products

Streamline your food processing line with an efficient aseptic processing syst...

Aseptic flash cooling for tomato and fruit concentrates

Achieve seamless aseptic processing while minimizing product degr...

Aseptic filler for fluids, concentrates, and particulates

Optimize your fluid and concentrate filling process with a hig...

Aseptic filler for juices and beverages

Ensure sterile packaging with precision. This aseptic filler offers high-speed, con...

Aseptic filler for packaged dairy and beverages

Ensure product sterility and extend shelf life efficiently with high-speed...

Aseptic bag filler for bulk containers

Eliminate spoilage events and ensure sterility in high-speed filling of bulk aseptic...

Uht plant for aseptic product treatment

Ensure optimal product quality and production safety with versatile UHT solutions f...

Aseptic filling system for sensitive beverages

Optimize your beverage production with an aseptic filling system that ensur...

Advanced aseptic filling system for beverage bottles

Seeking a sterilization and filling system that maximizes sterilizat...

Aseptic filling system for bag-in-box containers

Ensure sterility and precision in filling aseptic liquid products, with s...

Aseptic filling for high and low acid beverages

Ensure aseptic integrity while maximizing operational efficiency with a co...

Aseptic liquid dosing system

Ensure precise, sterile dosing of aseptic liquid products, enhancing product integrity and exte...

Aseptic filling system for milk-based drinks

Ensure sterile bottling of milk-based and sensitive beverages with this syste...

Blow/fill/seal system for aseptic liquid packaging

Achieve efficient aseptic packaging with a system that combines blow m...

Aseptic blow fill seal system

Ensure sterile, high-speed production of liquid pharmaceuticals by integrating a cutting-edge ...

High pressure aseptic sterilizer for tomato paste

Ensure your tomato paste achieves optimal safety and quality with a hig...

Aseptic filler for fruit juice and dairy products

Ensure sterile, high-speed filling of liquids and creams with precision...

Aseptic filler for fruit juices and purees

Ensure product integrity and shelf stability with a versatile filler designed t...

Aseptic filler for various liquid and semi-liquid food products

For manufacturers focused on quality, this aseptic filli...

Aseptic filler for fruit juice and puree

Ensure optimal product safety and quality with this aseptic filler, designed to ha...

Aseptic filling solution for fruit juice and dairy products

Ensure product integrity and safety with this aseptic fillin...

Aseptic rotary cup filling and closing solution

Maximize your production capacity with this cutting-edge aseptic solution,...

Aseptic dosing unit for enzymes and vitamins

Efficiently integrate precision ingredient dosing for enzymes and vitamins in...

Aseptic dosing system for heat-sensitive ingredients

Enhance product quality and reduce ingredient waste by precisely inj...

Aseptic tank with blending function for liquid food storage

Achieve seamless integration of aseptic buffering and in-lin...

Aseptic dosing unit for in-line ingredient addition

Optimize your production with precise aseptic dosing, minimizing ingr...

Aseptic dosing unit for sensitive ingredients

Ensure the stability of heat-sensitive ingredients with precise in-line dosi...

Aseptic tank for intermediate storage

Ensure safe and sterile storage for liquid and slurry products, minimizing product lo...

Aseptic tank for blending and buffering

Optimize your production line with a secure aseptic tank that ensures precise in-li...

High-speed aseptic carton filling solution

Maximize production efficiency and meet growing demand with this high-output fi...

Aseptic filling solution for tetra classic packaging

Experience efficient aseptic packaging with high-speed operation, of...

Aseptic carton filling system for tetra fino packaging

Elevate your production efficiency with a high-speed aseptic filli...

Filling system for tetra wedge aseptic packages

Optimize your production line with a reliable filling system designed to e...

Compact aseptic filling solution for versatile production

Maximize production line efficiency with a compact filling sys...

High-speed carton filler for aseptic packaging

Maximize production efficiency with this high-speed filling solution that e...

Aseptic filling solution for liquid food packaging

Optimize liquid food production with advanced aseptic filling, ensurin...

Freeze dryer & filling line aseptic isolator for cytotoxic products

Handle cytotoxic and high-potent drugs with precisi...

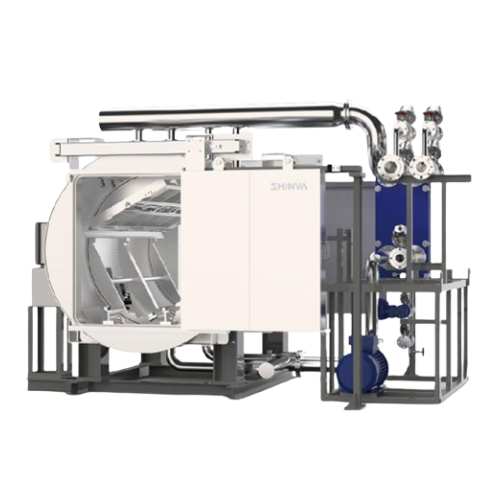

Pharmaceutical aseptic separator tumble dryer

Streamline moisture reduction with precision: this solution accelerates dryi...

Aseptic storage tank for aseptic products

Ensure uninterrupted aseptic product storage with this advanced tank system, des...

Robotic filler for aseptic pharmaceutical production

Streamline your aseptic filling process with high-speed robotic prec...

Aseptic filling technology for dairy products

Ensure product integrity and extend shelf life with a high-speed aseptic fil...

Aseptic filling machine for liquids and powders

Aseptic filling of containers such as vials, syringes, bottles, and cartri...

Aseptic FFS machine for UHT products

UHT products (ultra high temperature processing) such as sterilized milk, are products...

Aseptic vial cap sealing machine

Aseptic production methods are at the heart of the latest development in pharmaceuticals in...

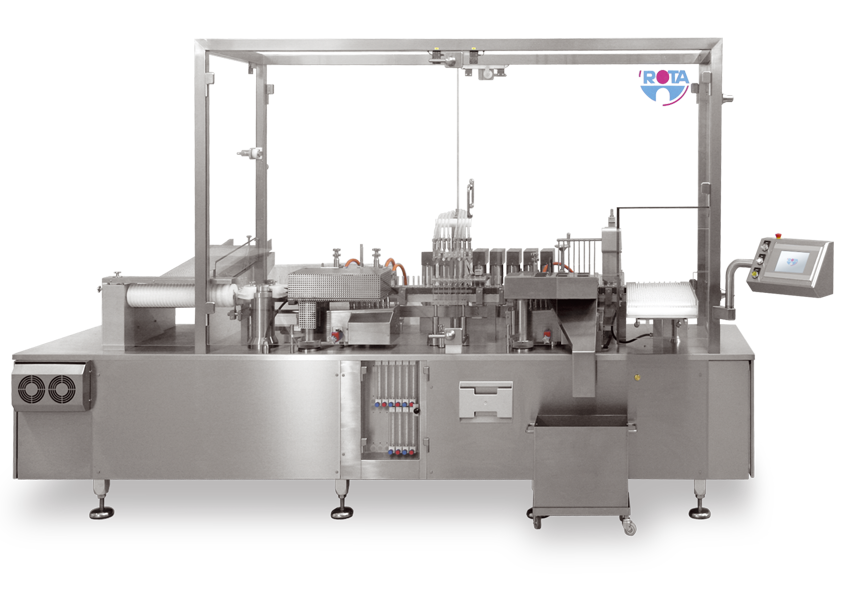

Aseptic automatic vial filling machine

Current and future developments in pharmaceuticals increasingly rely on aseptic prod...

High-speed aseptic injectable vial filling machine

Fill up to 24,000 vials per hour with pharmaceutical powders or liquid...

Aseptic liquid filler for vials

Compact modular aseptic filler of vials with parenteral medicines and freeze-dried products.

Uht sterilization for milk

Enhance your production line with advanced UHT sterilization, ensuring extended shelf-life and un...

Almond milk production system

Streamline your plant-based beverage production with a comprehensive system designed to finely...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

High shear mixer for emulsification

Achieve precise emulsification and dispersions with magnetic high shear technology, ens...

Nested syringe filling and stoppering line

Streamline your aseptic filling process with advanced machinery that handles ne...

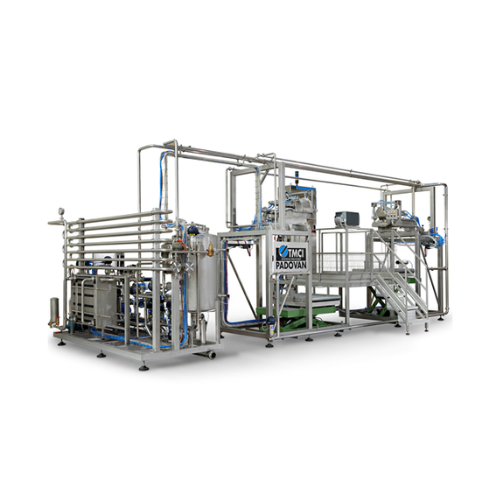

Uht system for milk products

Achieve optimal product safety and quality for dairy and plant-based beverages with precise UHT...

High-speed fill-finish system for ready-to-use components

Enhance aseptic fill-finish operations with a high-speed solut...

Horizontal vacuum paddle dryer for sensitive pharmaceutical ingredients

Achieve precise drying and mixing of sensitive ...

Sterile filling system for Iv bags

Ensure precise and sterile filling of IV and infusion bags with flexible, semiautomatic ...

Vial and syringe filling system for pharmaceuticals

Ensure aseptic precision in liquid formulation filling with a modular...

Vial filling for pharmaceuticals

Streamline your aseptic processing with vial filling machines that ensure sterile, precise,...

Plate sterilizer for low fiber content liquids and juices

Efficiently sterilize and prepare low-consistency liquids with...

Radiofrequency sterilizer for delicate food products

Streamline your food processing with radiofrequency technology, offe...

Fruit processing system for jams and marmalades

Optimize your fruit-based product manufacturing with equipment designed fo...

Tipping and filling line for bulk Api powder production

Ensure precise and aseptic handling of pharmaceutical powders wit...

Semi-automatic filling system for cell and gene therapy

Optimize your cell and gene therapy processes with a modular fill...

Rb-82 generators production plant

Ensure stringent aseptic conditions and efficient Sr-82/Rb-82 generator production with a...

Sterile robotic filling for ready-to-use vials and syringes

Achieve precise and contamination-free filling for biopharma...

Automated ioflupane i-123 injection dispensing solution

Ensure precision and efficiency in radiopharmaceutical production...

Rotary filling system for Rtu vials in pharma production

Optimize your sterile liquid and powder handling with a versatil...

Sterile liquid preparation system for pharmaceutical use

Ensure the sterility and precision of your liquid formulations w...

Hybrid bioprocess system for cell culture and purification

Streamline your bioprocessing operations with a versatile sol...

Plate heat exchanger sterilizer for food products

Ensure consistent product quality and microbiological stability in your...

Industrial homogenizers for liquid processing

Achieve consistent product quality and energy efficiency in liquid processin...

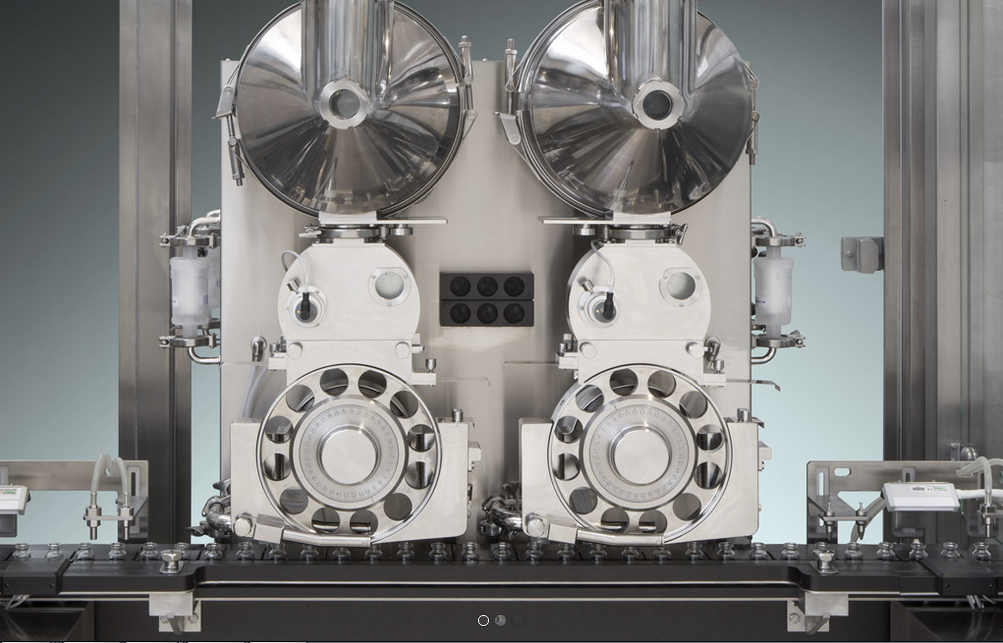

Nested fillers for vials, pre-filled syringes, and cartridges

Optimize your aseptic filling processes with precision dos...

High-speed ampoule filling unit

Ensure precision and speed with this cutting-edge solution designed for efficient filling an...

Gravity rotary filling for large infusion bottles

Ensure precise filling and secure stoppering of large infusion bottles ...

Multifruit processing line for wholemeal pulps and juices

Optimize your fruit processing capabilities with a skid-based ...

Peach, plum, and apricot juice processing line

Optimize your fruit processing capabilities with a multifunctional solution...

Pineapple juice extraction line

Streamline your pineapple processing with a complete solution designed to efficiently transf...

Banana purée production line

Maintain banana pulp quality by processing in a nitrogen atmosphere, ensuring fresh, oxidation-...

Coconut processing line for green coconut water and cream

Enhance your coconut processing with a fully automatic line th...

Direct Uht treatment for liquid foods

Optimize aseptic production with advanced UHT technology to preserve nutritional valu...

Indirect Uht treatment for dairy products

Ensure your beverages achieve extended shelf life with consistent quality using ...

Direct Uht processing for heat-sensitive liquid products

Achieve optimal taste and nutritional value in liquid foods thro...

Direct Uht processing system for dairy and plant-based beverages

Achieve ultra-high temperature treatment with minimal i...

Effective pasteurization system for beverage industry

Maximize beverage safety with efficient heating and cooling process...

Sterile lyophilised filler

Achieve precise weighing and contamination-free lyophilisation with our cutting-edge sterile fill...

Laminar air flow systems for pharmaceutical production

Ensure contamination-free production by maintaining unidirectional...

Biodecontamination unit for clean rooms and laboratories

Achieve reliable, 6-log bioburden reduction with this automated ...

Pharmaceutical liquid and powder filling solution

Achieve precise filling and capping of diverse formulations with a vers...

Automatic linear filling stoppering system for large volume vials

Ensure precise vial filling and secure sealing with a...

Single-mold continuous bottle Bfs solution

Optimize aseptic production with this advanced solution, offering superior ster...

Blow-fill-seal system for small volume injection production

Ensure precise aseptic liquid packaging with integrated blow...

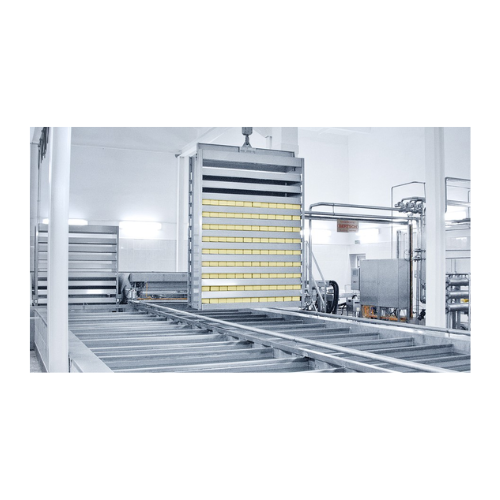

Automatic loading and unloading system for freeze-drying

Eliminate contamination risks and improve operational efficiency...

Semi-automatic filling solution for syringes and vials in isolators

Achieve precise aseptic fill-finish operations for ...

High-clean FFS machine for butter in mini portions

With the production of dairy products such as butter in mini portions ...

Standard FFS machine for spreads and sauces in mini portions

In the food industry, from a microbiological point of view,...

Nested syringe filling machine

Increasingly, pre-sterilized Ready To Use (RTU) nested vials, cartridges and syringes are the...

Microdosing machine for sterile powders

Fill sterile pharmaceutical powders into vials under aseptic conditions with a spee...

Bioprocessing liquid cell culture media

Streamline your bioprocessing with sterile liquid media solutions that ensure optim...

Automated system for cleaning in place (cip)

Ensure thorough, efficient cleaning of your production equipment with a syste...

In-line filling system for pharmaceutical products

Ensure precise and flexible filling of liquids, from sterile saline to...

Liquid filling system for medical and pharmaceutical products

Enhance your production capabilities with high-speed liqui...

Marmalade, sauces, nectars, and baby food processing solution

Maximize flexibility in your production line with a system...

Technetium-99m generator production line

Streamline your radiopharmaceutical production with our solution, ensuring precise...

Ra-223 dichloride production and dispensing suite

Ensure precise production of Ra-223 dichloride and related radiopharmac...

Cip cleaning systems for dairy processing plants

Optimize cheese production with precise curd handling and exceptional sti...

Cartridge and disposable syringe closing solution

Ensure precise closing of pre-filled syringes and cartridges with custo...

Carbonated drink filling solution for Pet bottles

Optimize your carbonated beverage production with an all-in-one filling...

Sugar reduction skid for fresh juice

Transform the way you produce juice with enzymatic technology that reduces sugar conte...

Hygienic filling system for short shelf life milk

Optimize your cold-chain distribution with a filling system engineered ...

Cold chain filling system for sensitive beverages

Ensure extended shelf-life for liquid dairy and sensitive beverages wit...

Insertion technology for sterile blow/fill/seal systems

Ensure sterility and precision in liquid pharmaceutical packaging...

Continuous mixing and filling system for viscous materials

Experience precise, pulsation-free mixing and filling of visc...

Tomato paste production line

Maximize tomato yield and flavor retention with this robust processing line designed to ensure ...

Acai berry processing line

Enhance your acai berry production efficiency with an automated line that transforms traditional ...

Apple, pear, and kiwi juice extraction line

Achieve high-yield juice production from apples, pears, and kiwis while retain...

Automatic mono-dose strip filling system

Optimize your liquid product packaging with a multi-functional system designed for...

Ultra-high temperature processor for premium liquid foods

Achieve superior product quality and flexibility with advanced...

Filling solution for water packaging

Achieve efficient packaging for a variety of beverages with this high-speed filling so...

Filling system for tetra brik 100 slim packages

Optimize your chilled product packaging with a high-speed filling system d...

Instant infusion Uht for baby food or milk concentrate processing

Achieve exceptional product quality with ultra-short,...

Infusion Uht plant for dairy products

Achieve precise thermal treatment with minimal product alteration, enhancing quality ...

Infusion Uht system for dairy and plant-based beverages

Efficiently extend the shelf life of dairy and plant-based bevera...

Ophthalmic filling solution for eye drops

Enhance your ophthalmic production line with a solution designed for precision f...

Ampoule filling and sealing line

Streamline your ampoule production with an integrated solution that expertly handles everyt...

Combi r&d ampoule and vial filling equipment

Optimize your R&D operations with a versatile machine designed for preci...

Nested syringe filling and stoppering system

Optimize your syringe production with precise filling and stoppering, ensurin...

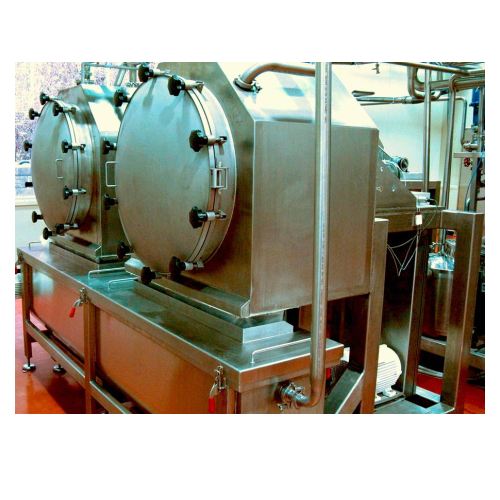

Moist heat sterilizer for liquid preparation

Ensure precise sterilization of pharmaceutical liquids and injectable biologi...

Rotary transfer system for pharmaceutical product filling

Ensure precise and hygienic filling of diverse pharmaceutical ...

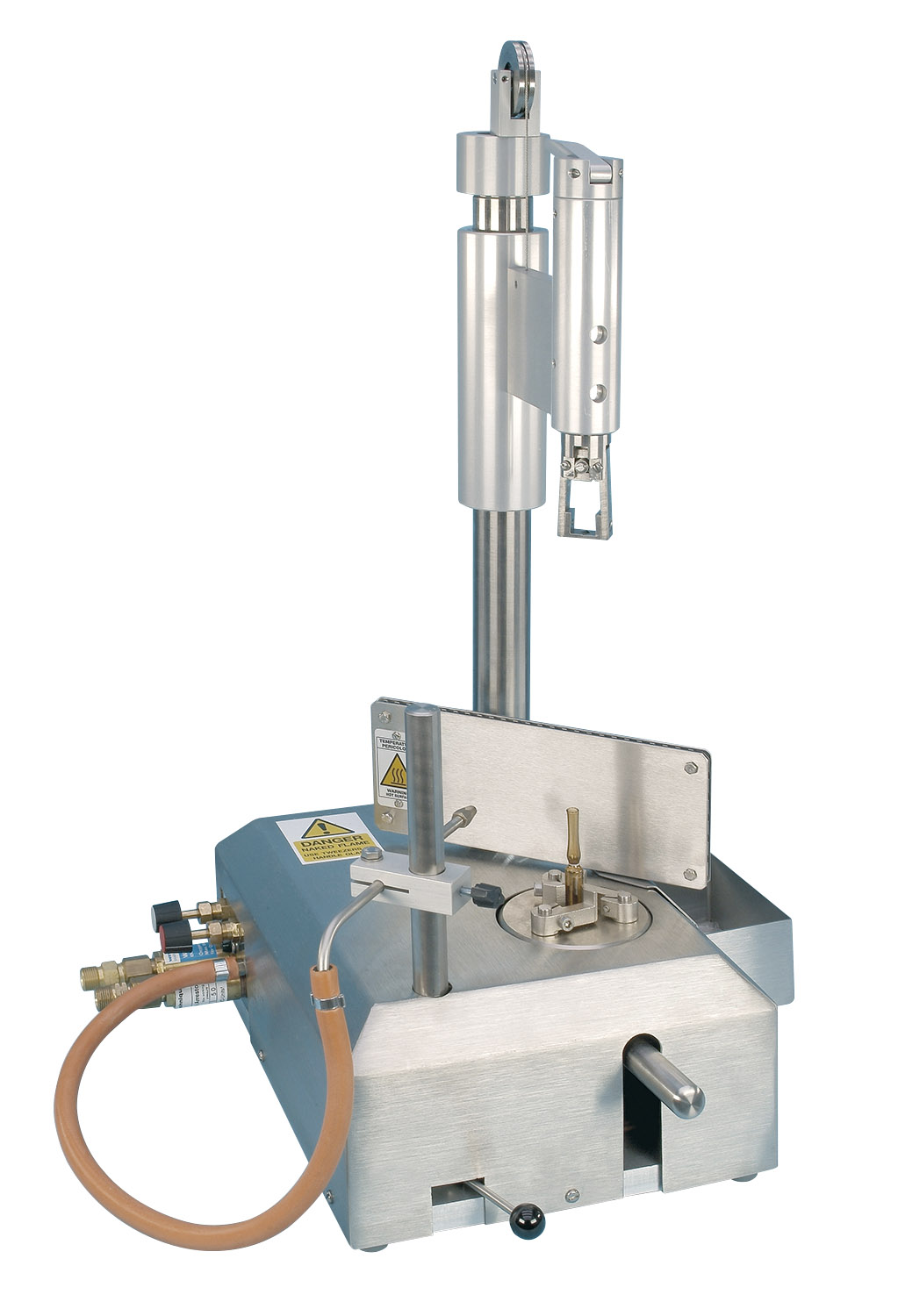

Benchtop peristaltic dispenser

When you fill vials and ampoules, high standards of hygiene are required to avoid the risk of...

Manual ampoule filler

When you fill ampoules it is essential to avoid wetting the inside walls of the container, as it may af...

Manual plastic tube sealing equipment

Working in labs or with small batch production lines where you have to seal plastic o...

Benchtop piston filling equipment for vials in trays

Vials are difficult to fill individually through manual methods due ...

Manual stoppering equipment for pre-filled syringes

Air present in the empty space of pre-filled syringes may prevent you...

Semi-automatic filler

When you are a small or a medium-sized manufacturer the manual filling processes might often lead to in...

Semi-automatic vial crimper

In a small production line, crimping vials manually can cause fatigue to your operator due to mu...

Up to four head automatic filling machine

When your consumer demand is increasing you will need new and more effective pac...

Big bag filling machine

Active pharmaceutical ingredients demand high handling standards to prevent cross-contamination. More...

Accurate multiple dosing system for powders

Dosing multiple powders in a batch process is time inefficient, especially whe...

High-speed powder dosing system

Balancing speed and accuracy in powder dosing is crucial to fulfilling production viability....

Powder micro-dosing system

Pharmaceutical powders in metered doses demand maximum filling precision. This is particularly ch...

Contamination free filling system

Liners for powder handling across industries must prevent contamination of materials to c...

Powder dosing system

Dosing of powder products must be done in a continuously controlled manner to provide a precise amount o...

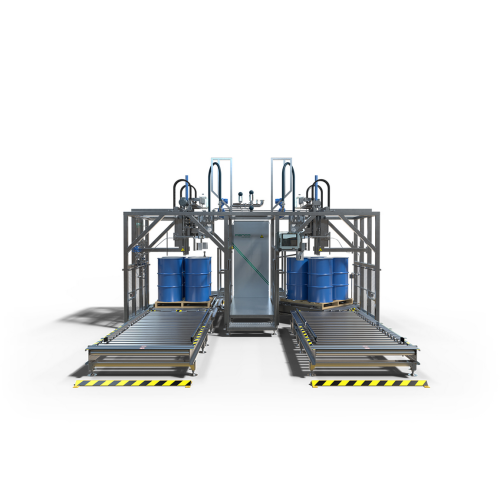

Drum filling system

Pharmaceutical and chemical products may be toxic or prone to contamination from environmental exposure. ...

Benchtop ampoule opening and closing equipment

The procedure for opening or closing ampoules requires you to handle gas an...

Ampoule filling machine

Filling ampoules or vials with parenteral fluids are an essential matter for which you need to consid...

Start-up sterile filling line for injectables

For smaller-scale production of vials and syringes for the injectables marke...

Start-up sterile filling line for ophthalmics

Commencing ophthalmic production requires sterile conditions and accurate me...

Table top sterile filling line for injectables

Where a compact solution is required for filling vials for the injectables ...

In-line monoblock linear filler & capper

In many food, chemicals and cosmetic industry processes it is vital to have a...

Flowmeter filler

For larger production runs of food, non-food and cosmetics industries, where accuracy and volume of filling i...

Compact monoblock filler

Filling and capping bottles and pots for food, chemical and cosmetics industries using separate mach...

Single head capper

For the stand-alone capping of bottles of up to 30 litre capacity for smaller-scale production you need a ...

Servo controlled filler

For food and non-food liquid products that are high foam or have a high viscosity a specialist fillin...

Multi-head capper

For the stand-alone capping of bottles of up to 2.5litre capacity you need a robust and flexible machine wi...

Sterile filling line for injectables

Sterile filling of liquids and powders for the pharmaceutical and cosmetic industries ...

Sterile filling line for ophthalmics

Demanding very high standards, the ophthalmic market requires quality solutions for fi...

Monobloc small volume liquid filler

These intermittent motion monobloc machines are designed for filling various liquids in...

High-speed small volume liquid filler

Fill liquid pharmaceutical, nutraceutical and cosmetic products in ampoules and bottl...