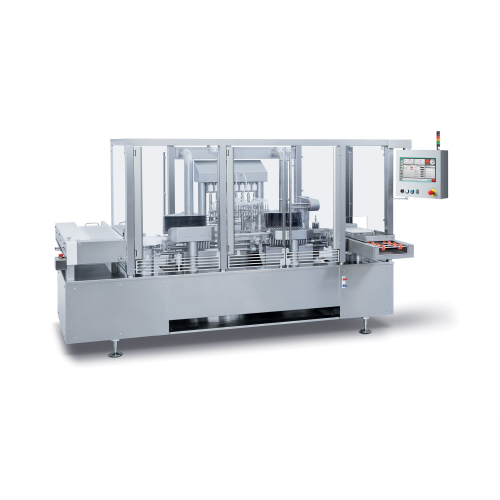

Aseptic ampoule filling and sealing solution

Ensure precise dosing and secure sealing of sterile liquid pharmaceuticals in ampoules and vials with aseptic technology designed to maintain the integrity and purity of injectable products throughout high-speed production lines.

Fills, Seals, and Sterilizes Ampoules and Vials

The RSF Series by Marchesini Group offers aseptic filling and sealing solutions tailored for liquid pharmaceuticals. This equipment is designed to address precision and sterility challenges in processing ampoules and vials, using rotary piston or peristaltic pumps to ensure accurate dosing. The machine integrates seamlessly into high-speed production lines with continuous operation capabilities, handling a range of products from 1 ml ampoules to 30R vials. Energy efficiency is enhanced through electronically controlled draw-back features to prevent needle dripping, while nitrogen and gas flushing stations, compliant with ATEX rules, ensure optimal process conditions. The RSF Series supports a throughput of 6,000 to 24,000 pieces per hour, adhering to GMP standards for pharmaceutical manufacturing. Its compact design facilitates easy access and cleaning, supported by automatic loading and unloading features. Customization is available to fit diverse production line arrangements, ensuring it meets specific needs of pharmaceutical and biotech facilities.

Benefits

- Enhances production efficiency with high-speed operation up to 24,000 pieces per hour.

- Maintains product integrity by ensuring aseptic filling and sealing processes.

- Reduces contamination risk through integrated "No ampoule – No Filling" function.

- Meets regulatory standards with ATEX-compliant oxygen and gas flushing systems.

- Simplifies maintenance with easy access and customizable configurations.

- Applications

- Pharmaceutical liquids, Liquid pharmaceuticals, Injectable products, Vials, Ampoules, Parenteral products, Aseptic solutions

- End products

- Insulin vials, Antibiotic vials, Dextrose injection ampoules, Adrenaline vials, Chemotherapy drugs, Vitamin b12 injections, Heparin solutions, Sterile saline solutions, Morphine ampoules, Vaccine doses

- Steps before

- Washing, Sterilizing

- Steps after

- Sealing, Stoppering, Inspection, Packing

- Input ingredients

- liquid products, open ampoules, closed ampoules, vials

- Output ingredients

- filled ampoules, sealed ampoules, rubber stoppered vials

- Market info

- Marchesini is renowned for manufacturing high-quality packaging machinery for the pharmaceutical and cosmetics industries, offering innovative, customized solutions with advanced automation and technology.

- Filling volume

- 1 ml – 25 ml for ampoules

- Filling volume

- 2R – 30R for vials

- Output Pieces/h

- 6, 000 to 24, 000

- Automation

- Automatic loading with motorized sanitary-plastic belts

- Dosing system

- Rotary Piston Pumps and/or Peristaltic Pumps

- Dosing volume adjustment

- Electronic adjustment

- Draw-back of dosing pumps

- Electronic adjustable to avoid needle dripping

- Flushing stations

- Oxigen, Gas and Nitrogen controlled by electronic mass-flow meters

- Compliance

- Oxigen and Gas ramp circuits in compliance with ATEX rules

- Sealing station

- Equipped with safety systems and controlled fumes extractors

- Operational repeatability

- Perfect

- Design

- Compact

- Automation level

- Automatic loading

- Sealing function

- No ampoule – No Filling

- Automation level

- Electronic adjustable dosing

- Gas Flushing

- Oxygen, Gas, Nitrogen

- Compliance with safety systems

- ATEX rules

- Flames ignition

- Automatic

- Automatic unloading

- On tray

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Ampoule type

- Open / Closed

- Compact footprint

- Yes

- Discharge method

- Automatic unloading on tray

- Control panel type

- Easy to use, access, and clean

- Integration possibilities

- In-line connection and automatic loading

- Discharge method

- Automatic unloading on tray

- Customization according to required line arrangement

- Yes